MBar

Active Member

With help and encouragement from several members, I was able to replace the seal without dropping the pan. I had a trans fluid leak that created a puddle under the car. After cleaning and inspecting, I determined it was the shift lever seal.. I ordered the seal and tool kit but was dreading doing this. Fortunately, got it done and it wasn't so bad at all.

Thank you to Dan Scully for the link to the parts.

Thank you to SAForwardLook for the invaluable tip to use a c-clamp.

I took photos along the way and I'm creating this post in hopes of helping the next guy.

I did this in the garage and with the car on stands as high as possible.

Here are the tools I used:

1/4 inch ratchet with small extensions and 7/16th socket

C-clamp

5/8 and 9/16 combo wrenches

Needle-nose pliers

Flat-head screwdriver

Small piece of plywood

Medium channel locks

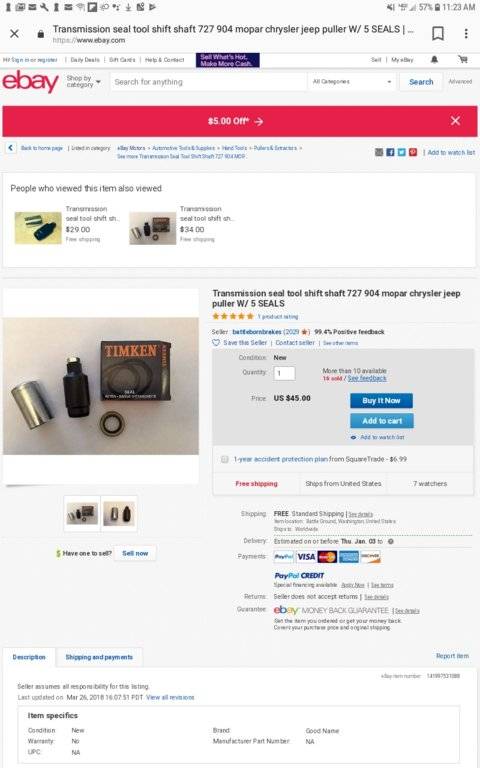

Seal and tool set from eBay which includes extractor and installer

Brake cleaner and paper towels

Patience and about an hour or 2

Thank you to Dan Scully for the link to the parts.

Thank you to SAForwardLook for the invaluable tip to use a c-clamp.

I took photos along the way and I'm creating this post in hopes of helping the next guy.

I did this in the garage and with the car on stands as high as possible.

Here are the tools I used:

1/4 inch ratchet with small extensions and 7/16th socket

C-clamp

5/8 and 9/16 combo wrenches

Needle-nose pliers

Flat-head screwdriver

Small piece of plywood

Medium channel locks

Seal and tool set from eBay which includes extractor and installer

Brake cleaner and paper towels

Patience and about an hour or 2

Last edited: