Dan Scully

Well-Known Member

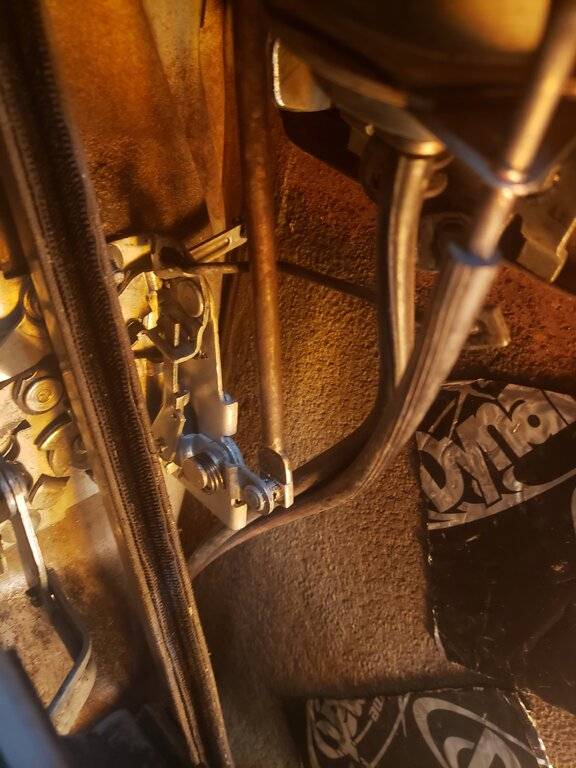

Got the door latches in the 64, I hate door work. First took forever second was easy after the learning curve of the first one. Converting to disc brakes and curios to see if I could make left hand studs work in the rotor. A friend has a Bridgeport and lathe, the studs where from my 68- a-100 that I changed to right hands. He had to turn them down slightly on the head and shank and then re knurled them. Only about a 1mm short thru the rotor, so that should not be a problem with the lug nuts.