This car is coming together slow, but everything we’ve done in our time building it has been worth it. It’s the little details that matter!!

Our first line of order yesterday was to get the torque converter into the 727 trans. I fought it for quite a while until I heard the 2 clicks. Once I got the first click, the second one almost immediately followed and it sat in there a good ways into the bellhousing.

Then I just mocked up to starter to verify things where as they should be…

I filled up the torque converter with about a quart of ATF +4. I know to some it’s overkill, but with a fresh and entirely new rebuild - I thought “might as well.” Getting the transmission bolted to the block wasn’t as hard as I thought it’d be! The little cogs built into the block that support the trans helped me to get a free hand and finger tighten the top two bellhousing bolts to the block. I used lock washers for good measure.

This thing is long!!! You may remember, I had a really hard time getting the transmission crossmember into the car, so we didn’t remove it. I believe that if I had removed it - it would’ve made the install MUCH easier, as we had to wrestle the engine in. The oil pan was getting hung up on the front crossmember, and the tail shaft stuck on a part of the rear crossmember… but with some coercing and twisting around we were able to get the engine in!

Need to touch up some paint in areas that got scraped, but I’ve quickly learned things never go too easy when it comes to doing this stuff…

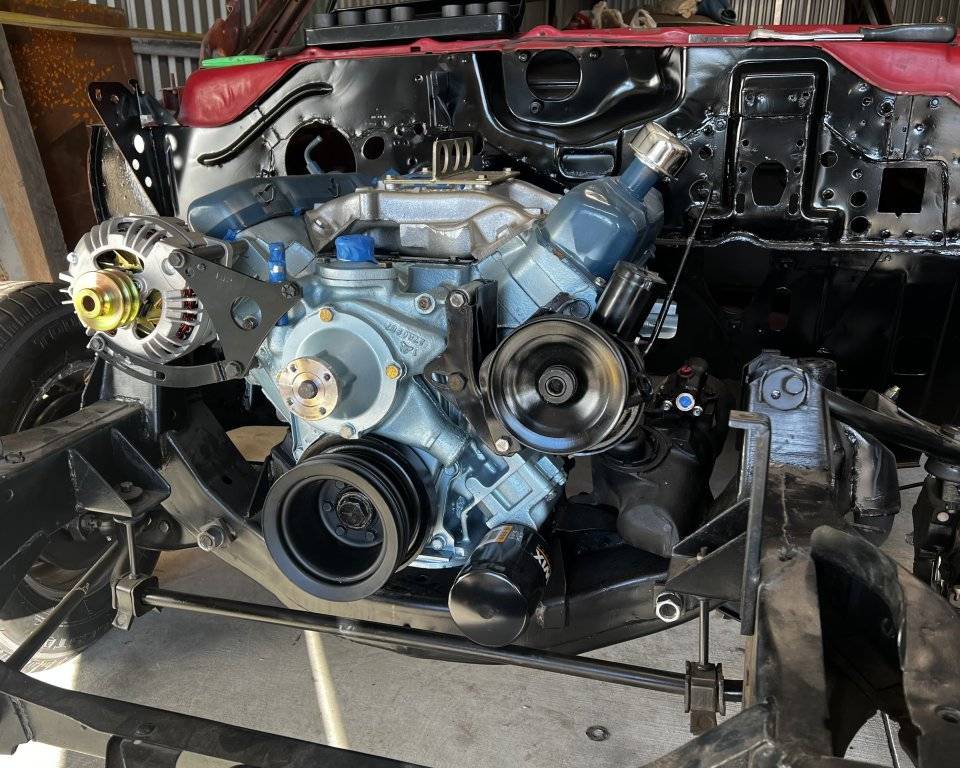

Some side views!

and one up top…

Next is to get the clutch / fan mounted up and run the water pump / alternator belt. Going to leave the steering pump off for now, but I have both! Going to set up my core support as well and install radiator w/ fan shroud. Fingers crossed the break in process goes well (whenever that might be.)

Our first line of order yesterday was to get the torque converter into the 727 trans. I fought it for quite a while until I heard the 2 clicks. Once I got the first click, the second one almost immediately followed and it sat in there a good ways into the bellhousing.

Then I just mocked up to starter to verify things where as they should be…

I filled up the torque converter with about a quart of ATF +4. I know to some it’s overkill, but with a fresh and entirely new rebuild - I thought “might as well.” Getting the transmission bolted to the block wasn’t as hard as I thought it’d be! The little cogs built into the block that support the trans helped me to get a free hand and finger tighten the top two bellhousing bolts to the block. I used lock washers for good measure.

This thing is long!!! You may remember, I had a really hard time getting the transmission crossmember into the car, so we didn’t remove it. I believe that if I had removed it - it would’ve made the install MUCH easier, as we had to wrestle the engine in. The oil pan was getting hung up on the front crossmember, and the tail shaft stuck on a part of the rear crossmember… but with some coercing and twisting around we were able to get the engine in!

Need to touch up some paint in areas that got scraped, but I’ve quickly learned things never go too easy when it comes to doing this stuff…

Some side views!

and one up top…

Next is to get the clutch / fan mounted up and run the water pump / alternator belt. Going to leave the steering pump off for now, but I have both! Going to set up my core support as well and install radiator w/ fan shroud. Fingers crossed the break in process goes well (whenever that might be.)