Gerald Morris

Senior Member

Despite the 1968 vintage of the body, I'm running a 1966 engine and transmission in Gertrude. After upgrading to the Edelbrock 1405, I haven't had a kickdown, despite my attempts at adjusting it as per the 1966 FSM. I now suspect nothing I do with the 2 barrel bellcrank and linkage will work. Despite Edelbrock's instructions as given here,

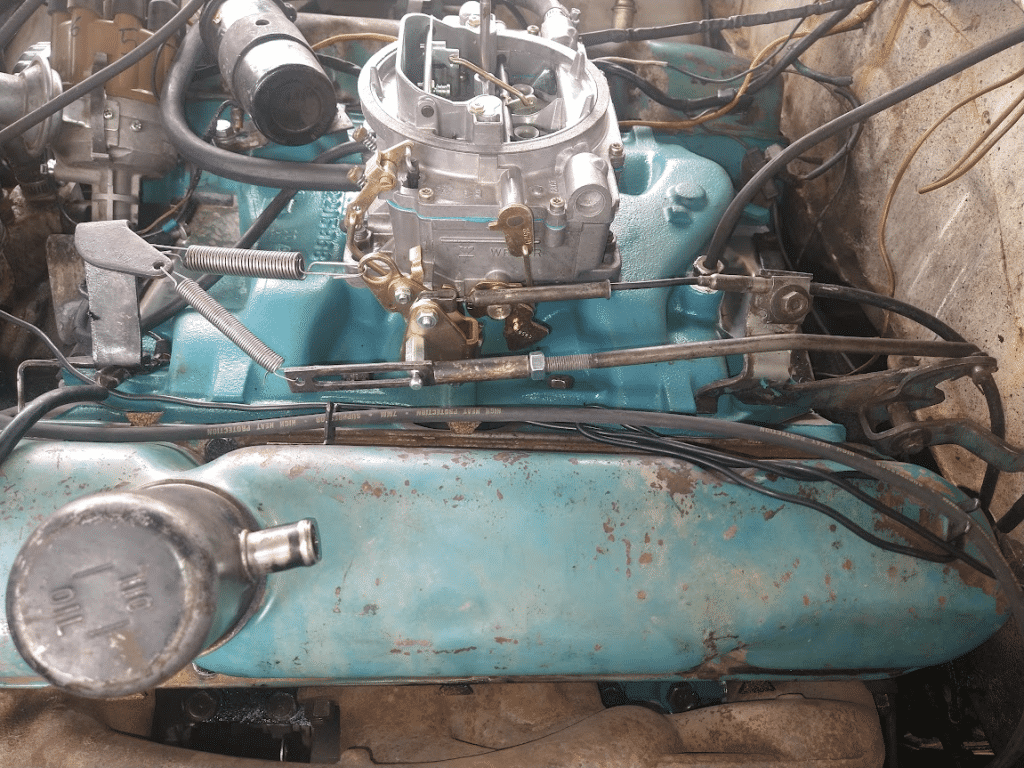

which sufficed for the THROTTLE, I now expect to kick down more cash to get a working kickdown. As usual, good Moparian references from the vendor can't be had beyond a few small adapters, which can be seen in use below.

The throttle adapter, stud and a nut from their kickdown rod extender are all I have installed on my linkage. That extender extended the length of my kickdown rod beyond useful length. The fine thread nut helps a little bit...

Do any of you Wise Elders know of an optimal hardware solution here? I've seen a number of after market options for 4 barrel carburetor kickdown and throttle adapters meant for the 727 and B/RB engines, and have seen some OEM Mopar hardware too. Any helpful advice, and/or hardware for the right price will be MUCH appreciated! While I have got the shifting how I like it, with a little SNAP, but not too much, I don't want to ruin this transmission, and prefer a working kickdown to having to drop it into the lower gear from the column shifter.

which sufficed for the THROTTLE, I now expect to kick down more cash to get a working kickdown. As usual, good Moparian references from the vendor can't be had beyond a few small adapters, which can be seen in use below.

The throttle adapter, stud and a nut from their kickdown rod extender are all I have installed on my linkage. That extender extended the length of my kickdown rod beyond useful length. The fine thread nut helps a little bit...

Do any of you Wise Elders know of an optimal hardware solution here? I've seen a number of after market options for 4 barrel carburetor kickdown and throttle adapters meant for the 727 and B/RB engines, and have seen some OEM Mopar hardware too. Any helpful advice, and/or hardware for the right price will be MUCH appreciated! While I have got the shifting how I like it, with a little SNAP, but not too much, I don't want to ruin this transmission, and prefer a working kickdown to having to drop it into the lower gear from the column shifter.