Well, I'll be listening to the rumbles of big blocks while you "Enjoy the Silence". Haha!Right now I'm not sure.

I'm not going the Saturday, for sure. It coincides with Depeche Mode playing in New Orleans and my wife wouldn't pass that up...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1966 Fury III - Unfinished Project

- Thread starter Philip Andrews

- Start date

Philip Andrews

Well-Known Member

If the weather stays as forecast, I may head down on the first Sunday.Well, I'll be listening to the rumbles of big blocks while you "Enjoy the Silence". Haha!

Philip Andrews

Well-Known Member

Tried to catch the same angle. Definitely an improvement.

Phil

Philip Andrews

Well-Known Member

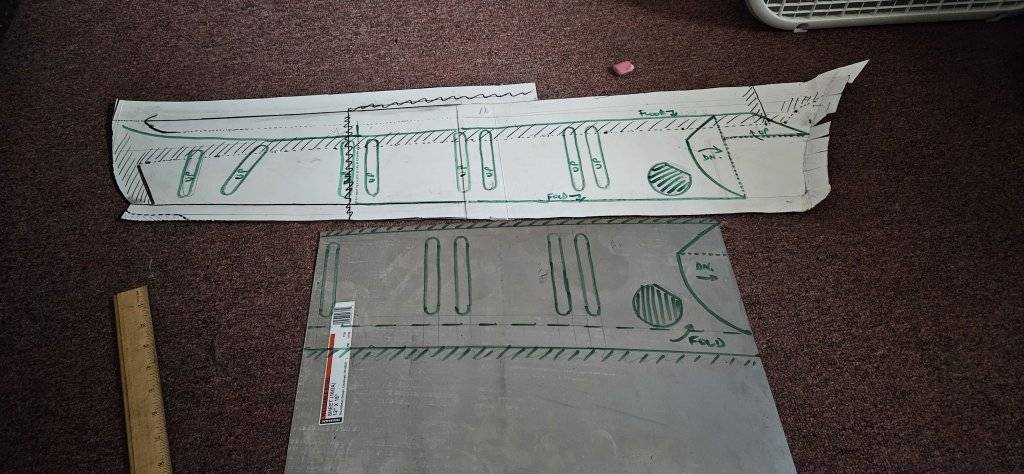

First of the inner panels to go on the inner edge of the quarter. This one's measured correctly.

That's from the end of the floor to the upkick panel. Using the outer quarter template to measure up.

Phil

That's from the end of the floor to the upkick panel. Using the outer quarter template to measure up.

Phil

Philip Andrews

Well-Known Member

Bash bash bash

Philip Andrews

Well-Known Member

Trimmed and adjusted, now the section fits. Think I may have to redo the arch profile though.

Phil

Phil

Philip Andrews

Well-Known Member

I'll be headed to Mississippi tomorrow in this.

Keep an eye open if you're there, flag me down if you recognize me!

Cruising up and down the boulevard.

Once the Fury is done, I'll take the same photo if I can there.

Phil

Keep an eye open if you're there, flag me down if you recognize me!

Cruising up and down the boulevard.

Once the Fury is done, I'll take the same photo if I can there.

Phil

Last edited:

Philip Andrews

Well-Known Member

Got the carburetor and ignition tuned up reasonably well. Runs and idles now without being too stubborn.

Holds good fuel pressure. Secondaries work too which is good.

Need to get back to the sheet metal on this.

Phil

Holds good fuel pressure. Secondaries work too which is good.

Need to get back to the sheet metal on this.

Phil

Philip Andrews

Well-Known Member

Surprisingly, this aluminum trim has remained shiny, despite being bare polished metal

I think the rest should tolerate being cleaned up. I need to get some paint thinners to strip the paint off the trim.

Phil

I think the rest should tolerate being cleaned up. I need to get some paint thinners to strip the paint off the trim.

Phil

Philip Andrews

Well-Known Member

Well, help me understand.

Pulled the pinion carrier off.

Undid the nut, knocked the back of it one side then the other until it came off the splines.

Knocked it back on to keep it sealed but now it's wobbly. And it leaks.

Will the pinion nose bearing pull out that way?

Phil

Pulled the pinion carrier off.

Undid the nut, knocked the back of it one side then the other until it came off the splines.

Knocked it back on to keep it sealed but now it's wobbly. And it leaks.

Will the pinion nose bearing pull out that way?

Phil

Last edited:

rkrochen

Senior Member

I guess the first thing is why did you remove the yoke. Need a bit more info.Well, help me understand.

View attachment 624244

Pulled the pinion carrier off.

Undid the nut, knocked the back of it one side then the other until it came off the splines.

Knocked it back on to keep it sealed but now it's wobbly. And it leaks.

Phil

Not sure if this diff utilizes a crush sleeve to maintain preload. If it did there is a good chance it’s not tight enough. Also you may have damaged the seal when you did this procedure.

Philip Andrews

Well-Known Member

The yoke has been hogged out on one side and has half a screw stuck in the other. It is u/s and needs replacement.I guess the first thing is why did you remove the yoke. Need a bit more info.

Not sure if this diff utilizes a crush sleeve to maintain preload. If it did there is a good chance it’s not tight enough. Also you may have damaged the seal when you did this procedure.

The seal is still ok; the pinion now wobbles about, it didn't when I started.

Philip Andrews

Well-Known Member

Yup, looks like I've smashed the preload sleeve. Superb.

Guess I'll get a bearing if it needs it, seal and redo the nose of the axle while I'm at it.

Phil

Guess I'll get a bearing if it needs it, seal and redo the nose of the axle while I'm at it.

Phil

Last edited:

It happens to the best (or worst, like me) of us. Live and learn, parts are available, make it good!

rkrochen

Senior Member

Usually if you over tighten the nut it will squash the sleeve and the end result will be too much preload on the bearings. This will result in a very tight pinion not loose as you describe. I suspect you didn’t tighten it enough. I always check the number of threads showing prior to removing the nut. On reassembly I check the threads and rotate the pinion to see if it is getting too tight.Yup, looks like I've smashed the preload sleeve. Superb.

Guess I'll get a bearing if it needs it, seal and redo the nose of the axle while I'm at it.

Phil

Philip Andrews

Well-Known Member

It's flopping about like the bearing has collapsed. I'll pull it apart again tomorrow if I have time and get a flashlight in there to see.Usually if you over tighten the nut it will squash the sleeve and the end result will be too much preload on the bearings. This will result in a very tight pinion not loose as you describe. I suspect you didn’t tighten it enough. I always check the number of threads showing prior to removing the nut. On reassembly I check the threads and rotate the pinion to see if it is getting too tight.

Phil

LocuMob

Fluid Technician with a hat

489 case is the only one that uses a crush sleeve. 741 & 742 cases don't.Yup, looks like I've smashed the preload sleeve. Superb.

Guess I'll get a bearing if it needs it, seal and redo the nose of the axle while I'm at it.

Phil

Philip Andrews

Well-Known Member

I need to go under tomorrow in the light and see which casting number I have.489 case is the only one that uses a crush sleeve. 741 & 742 cases don't.

I found a useful descriptive reference which provides cross reference and sizing details.

Thanks!

Phil

Philip Andrews

Well-Known Member

Okay, so it's a 741, which matches the spec of the car.

So that means the pinion preload is set internally with shims and the yoke bolt just does up to a static lb/ft figure?

Phil

So that means the pinion preload is set internally with shims and the yoke bolt just does up to a static lb/ft figure?

Phil

Philip Andrews

Well-Known Member

Stand up and raise your hand, who said "you didn't tighten it enough".

Yes.

It's all back together again.

Thanks

Phil

Yes.

It's all back together again.

Thanks

Phil

Similar threads

- Locked

- Replies

- 3

- Views

- 522

- Replies

- 0

- Views

- 667

- Locked

- Replies

- 0

- Views

- 780

- Replies

- 19

- Views

- 2K