thethee

Senior Member

Okay, maybe a more fitting title would be 'A guide to my Speed Control Servo' but I'm sure a lot of you have the same one as me. It's the later style unit with one vacuum connection and three electrical connections.

I've been meaning to do a thread on it for a while now and I finally got around to it. I'm sure a lot of you have seen the Chrysler Master Tech about the speed control, it has been around the forum several times, but here it is once more:

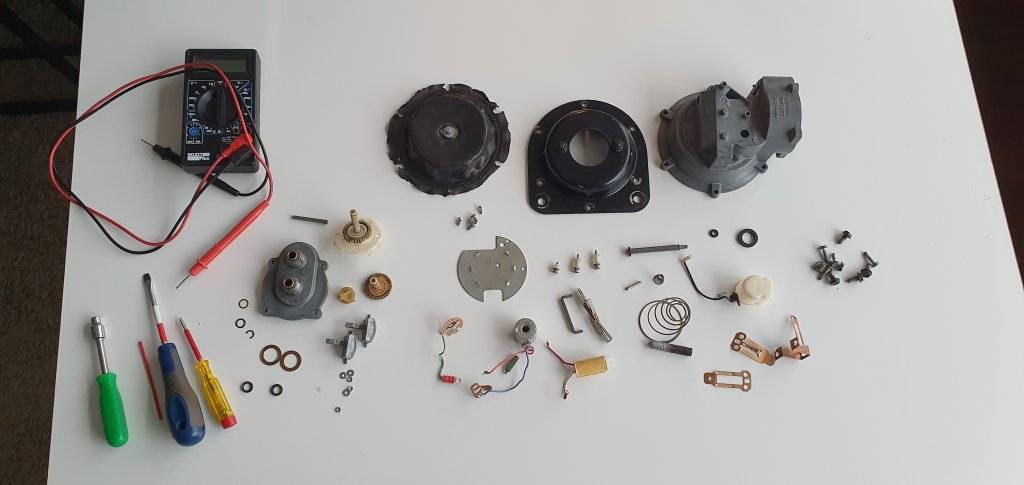

A key line of that video is at the beginning; "Although this servo is serviced only as a complete assmbly [...]". But I'm a fixer, I like to take things apart, understand how they're supposed to work, and then try to put it back together. So I did. I've completely disassembled it and I've pretty much figured out how it works. I'm planning on documenting putting it back together here so it can maybe be of any help to you guys if you want to try fixing your own. Or at least be able to diagnose it.

Starting point is a completely empty housing and I'll end up with the complete unit so disassembly will pretty much be the reverse order of the thread.

I've been meaning to do a thread on it for a while now and I finally got around to it. I'm sure a lot of you have seen the Chrysler Master Tech about the speed control, it has been around the forum several times, but here it is once more:

A key line of that video is at the beginning; "Although this servo is serviced only as a complete assmbly [...]". But I'm a fixer, I like to take things apart, understand how they're supposed to work, and then try to put it back together. So I did. I've completely disassembled it and I've pretty much figured out how it works. I'm planning on documenting putting it back together here so it can maybe be of any help to you guys if you want to try fixing your own. Or at least be able to diagnose it.

Starting point is a completely empty housing and I'll end up with the complete unit so disassembly will pretty much be the reverse order of the thread.