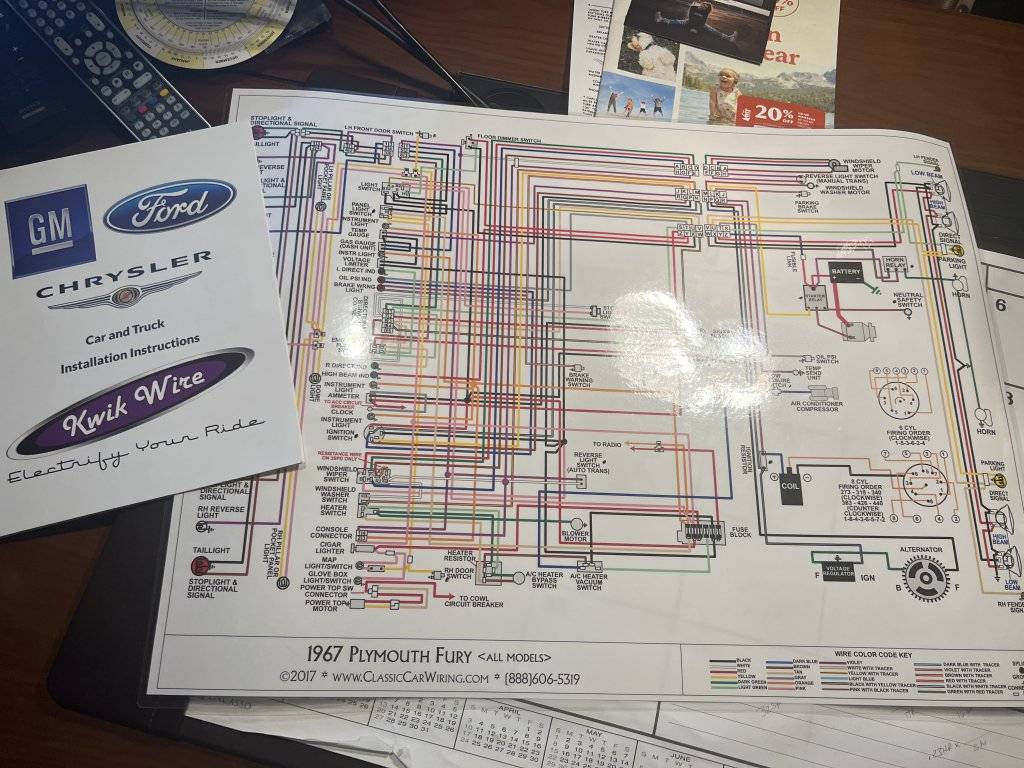

howdy folks. i a have a 67 fury III that needs to be rewired. The wiring in it now is the original wiring when my grandmother bought the thing - hence it is old. i went to a restoration shop here in Tomball TX and these folks wanted almost $10K to do the work (and that is with me providing the wiring harness). That being said, I must try and do this myself. Im a pretty handy fella - not a moron but certainly not an electrician. I have the original service manual as well. here is my question... is there a good resource out there I can use to learn how to do this job? The diagrams I have (see below) are pretty good, but there are some details left out. There are some assumptions made regarding the skill level of someone purchasing the materials you see below. I am slowly watching every video I can find. I thought maybe I could just ask and see what, if anything, is out there. any help is appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

electrical rewiring

- Thread starter craigl

- Start date

There might be a few upgrades (as the ammeter bypass that's documented well in this forum) and a few other places to look at, BUT unless there is a problem, no real need to replace the whole car's wiring just because "it's old", to me.

Certainly, clean out the accumulation of gunk in the wiring bulkhead connector sides (inside and outside) on the firewall. Ensure that all of the connectors connect firmly and tightly, too. Then replace whatever protective coatings which might have been in them at the factory. Sometimes, the courtesy light switches will fail, so inspecting them and the related trunk light switch, can be good. Summarily replacing them might not be a good idea as I suspect any new ones (not NOS items, but replacement items from other sources) might not be as good as the OEM items.

As you can see from the wiring schematics, there are main circuits which feed a multitude of other circuits. You might trace and inspect those feed circuits' connections for any prior owner-altered (or somebody else doing it) modifications to prevent future issues.

Do inspect each of the light bulb sockets and such, too. Look for any evidence of "heat" from discoloration of the insulation.

So, in general, just good inspection and maintenance operations. Re-wiring the entire car can be a suboptimal investment with few paybacks. Take care of that car and give it lots of loving care!

Just some thoughts and observations,

CBODY67

Certainly, clean out the accumulation of gunk in the wiring bulkhead connector sides (inside and outside) on the firewall. Ensure that all of the connectors connect firmly and tightly, too. Then replace whatever protective coatings which might have been in them at the factory. Sometimes, the courtesy light switches will fail, so inspecting them and the related trunk light switch, can be good. Summarily replacing them might not be a good idea as I suspect any new ones (not NOS items, but replacement items from other sources) might not be as good as the OEM items.

As you can see from the wiring schematics, there are main circuits which feed a multitude of other circuits. You might trace and inspect those feed circuits' connections for any prior owner-altered (or somebody else doing it) modifications to prevent future issues.

Do inspect each of the light bulb sockets and such, too. Look for any evidence of "heat" from discoloration of the insulation.

So, in general, just good inspection and maintenance operations. Re-wiring the entire car can be a suboptimal investment with few paybacks. Take care of that car and give it lots of loving care!

Just some thoughts and observations,

CBODY67

I am in agreement with CBODY67 , if it ain’t broke don’t fix it . You will be opening up a whole new can of problems that will end up costing you $$$$ to get back to a working state .

Agreed - you can do this yourself, and learn a lot in the process. Yes, it's time consuming, but it's WAY cheaper than a shop doing it. Do NOT attempt to use a wiring kit - they're a pain in the butt, and it quickly becomes a nightmare. The factory harnesses are generally excellent, and can easily be repaired and refurbished.

Invest in some rolls of good 12, 14 and 16 AWG automotive wire in the standard 6 colours (parts store), quality butt connector kits (parts store), some heat shrink tubing kits (parts store) and some non-adhesive wire wrap (eBay).

Remove each individual wiring harnesses one at a time and take lots of photos of how they're installed, and label the connections.

Lay it out on the shop floor and compare to the wiring diagrams in your service manual. Some diagrams are tucked away in other sections outside of the Electrical section - you may have to search around to find them... things like console, power seats, AC, convertible top...

Repair any pinches, abrasions etc., and remove the terminals from each connector block (one at a time!!), and clean them with a wire brush and/or replace them with the same ones. The connectors are available from multiple sources on eBay. They are known as Packard Connectors, and they have a special crimping tool that is worth investing in.

You can even get new bulkhead connector kits on eBay, and the parts to rebuild the fuse box with new connectors.

Once you have things in hand, then you can do the Bulkhead power wire bypasses, and the Amp gauge bypass or safety upgrade.

You can do this. Save your money, fix what's there, and have the satisfaction of accomplishing a task that makes many people's eyes glaze over.

I can help - PM me with questions.

Invest in some rolls of good 12, 14 and 16 AWG automotive wire in the standard 6 colours (parts store), quality butt connector kits (parts store), some heat shrink tubing kits (parts store) and some non-adhesive wire wrap (eBay).

Remove each individual wiring harnesses one at a time and take lots of photos of how they're installed, and label the connections.

Lay it out on the shop floor and compare to the wiring diagrams in your service manual. Some diagrams are tucked away in other sections outside of the Electrical section - you may have to search around to find them... things like console, power seats, AC, convertible top...

Repair any pinches, abrasions etc., and remove the terminals from each connector block (one at a time!!), and clean them with a wire brush and/or replace them with the same ones. The connectors are available from multiple sources on eBay. They are known as Packard Connectors, and they have a special crimping tool that is worth investing in.

You can even get new bulkhead connector kits on eBay, and the parts to rebuild the fuse box with new connectors.

Once you have things in hand, then you can do the Bulkhead power wire bypasses, and the Amp gauge bypass or safety upgrade.

You can do this. Save your money, fix what's there, and have the satisfaction of accomplishing a task that makes many people's eyes glaze over.

I can help - PM me with questions.

mrfury68

Senior Member

Like the previous posts mentioned, if it ain’t broke don’t fix it. If you are having issues with a couple of circuits, troubleshoot that circuit only. These wiring systems were pretty stout. The bulkhead connection was the Achilles heel. That is fairly basic to correct though with inspection & proper cleaning of terminals. Those rewire kits are great if you are building a street rod or some type of custom car. Remember, keep it simple. One circuit at a time. Proper grounding is essential. You don’t want to start hacking into an otherwise old but still good factory harness. Hope this info helps.

65CopCar

Active Member

I have a lot of experience with car wiring.

There is NO WAY I would be trying to use an aftermarket kit to rewire this car. Just buy replacement engine bay harnesses - available from several sources or as previously stated, just duplicate the existing harnesses. But if you do it yourself you need the correct terminals and have (and know how to use) correct crimpers. Many of the plastic connector bodies are tough to find or not available so you end up reusing the old ones or use ones that are close. And the wires ones that are cloth wrapped - you are not duplicating that cloth unless you buy it from someone and and good luck with that - never found one for my 65 Fury so reused the old ones.

For wire you want a cross linked insulation (generally XLPE) such as this one - they are available in several insulation thicknesses:

General Cable 131882-91A Automotive Cross-Link Wire | Waytek

Store bought wire is generally garbage pvc insulation.

Under dash harnesses are very complicated and generally do not go bad. They just get cleaned up. Some harnesses such as the one going to the trunk are probably not available for your car. Just clean those up and replace the connectors if necessary.

$10k is insane.........

There is NO WAY I would be trying to use an aftermarket kit to rewire this car. Just buy replacement engine bay harnesses - available from several sources or as previously stated, just duplicate the existing harnesses. But if you do it yourself you need the correct terminals and have (and know how to use) correct crimpers. Many of the plastic connector bodies are tough to find or not available so you end up reusing the old ones or use ones that are close. And the wires ones that are cloth wrapped - you are not duplicating that cloth unless you buy it from someone and and good luck with that - never found one for my 65 Fury so reused the old ones.

For wire you want a cross linked insulation (generally XLPE) such as this one - they are available in several insulation thicknesses:

General Cable 131882-91A Automotive Cross-Link Wire | Waytek

Store bought wire is generally garbage pvc insulation.

Under dash harnesses are very complicated and generally do not go bad. They just get cleaned up. Some harnesses such as the one going to the trunk are probably not available for your car. Just clean those up and replace the connectors if necessary.

$10k is insane.........

IMHO, I would stay far away from the aftermarket "fits all" type wiring harnesses (example Painless or Kwik Wire).

The best option is a reproduction harness from one of the suppliers.

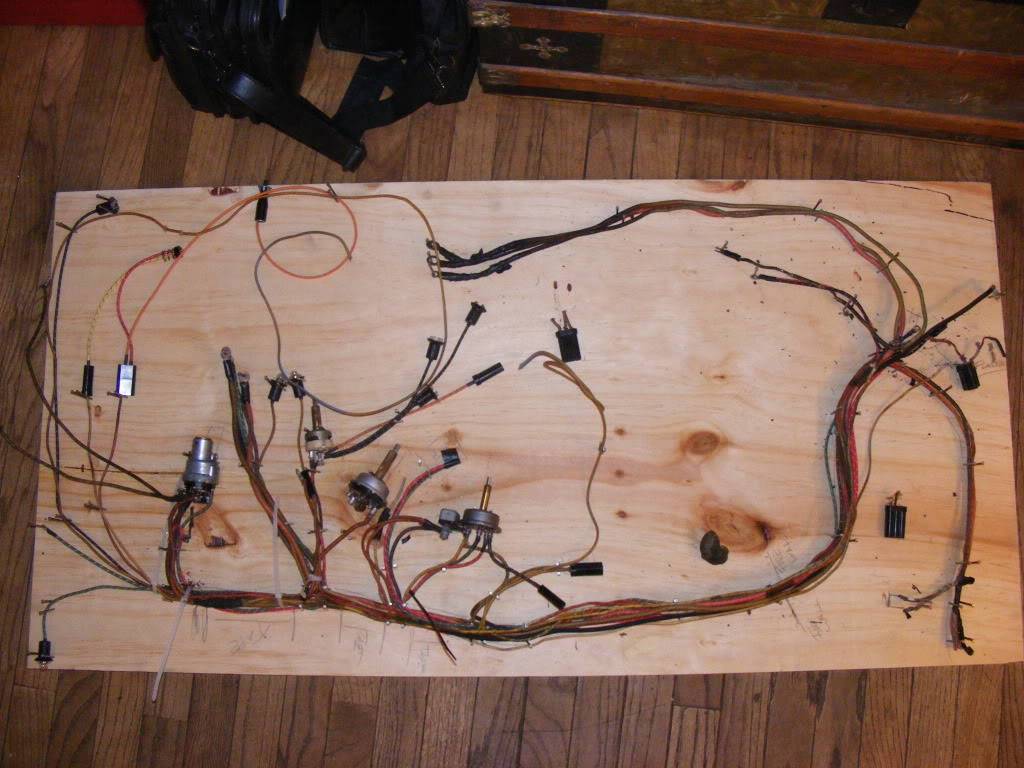

Another option, and I've done this, is to use a piece of plywood and some finishing nails. Lay the harness and outline it with the nails. Unwrap and remove/replace each wire one at a time. The best source I've found for good quality wire WITH the correct markings (tracer stripes) are these guys. The have a lot of the connectors too. Rhode Island Wiring Service Inc.

The best option is a reproduction harness from one of the suppliers.

Another option, and I've done this, is to use a piece of plywood and some finishing nails. Lay the harness and outline it with the nails. Unwrap and remove/replace each wire one at a time. The best source I've found for good quality wire WITH the correct markings (tracer stripes) are these guys. The have a lot of the connectors too. Rhode Island Wiring Service Inc.

I forgot to add this... If you do rework your harness, use some non-adhesive electrical tape. Why "non-adhesive"? The factory harness was wrapped with it so you can unwrap a section to test a wire easily.

1 Roll Factory Electrical Non Adhesive Wiring Harness Friction Tape Oem C Nos Oe | eBay

1 Roll Factory Electrical Non Adhesive Wiring Harness Friction Tape Oem C Nos Oe | eBay

That's the very tape I was referring to in my post. Thanks for the link!I forgot to add this... If you do rework your harness, use some non-adhesive electrical tape. Why "non-adhesive"? The factory harness was wrapped with it so you can unwrap a section to test a wire easily.

1 Roll Factory Electrical Non Adhesive Wiring Harness Friction Tape Oem C Nos Oe | eBay

A quick Google search turns up these pre-made ready fit correct harnesses for your car:

NEW 1968 Fury Polara Monaco Chrysler 383 440 v8 Engine Wiring Harness W/ ECU | eBay

Mopar Restoration and Performance C-BODY ELECTRICAL, Wiring Harnesses

Herb's seems to have a lot of the parts in a One-Stop shop. Fuse boxes, engine harnesses for use with or without electrictronic ignition, and likely lots of the parts available to repair your existing harnesses.

NEW 1968 Fury Polara Monaco Chrysler 383 440 v8 Engine Wiring Harness W/ ECU | eBay

Mopar Restoration and Performance C-BODY ELECTRICAL, Wiring Harnesses

Herb's seems to have a lot of the parts in a One-Stop shop. Fuse boxes, engine harnesses for use with or without electrictronic ignition, and likely lots of the parts available to repair your existing harnesses.

Last edited:

65CopCar

Active Member

Bill Evans made my Fury harnesses - he is probably the most cost effective you will find. I bought my 69 GTX harnesses from year one.

Evans Wiring Harnesses

Evans Wiring Harnesses

Agreed, Evans is also a great place to shop.

65CopCar

Active Member

Ross - in case you didn't know, those are the same vendor. Mike at Obsolete still uses FMMPAR on ebay and he bought Herbs. So FMMPAR, Obsolete Auto and Herbs are all the same now - all owned by Mike. I know Mike and like him a lot.A quick Google search turns up these pre-made ready fit correct harnesses for your car:

NEW 1968 Fury Polara Monaco Chrysler 383 440 v8 Engine Wiring Harness W/ ECU | eBay

Mopar Restoration and Performance C-BODY ELECTRICAL, Wiring Harnesses

Herb's seems to have a lot of the parts in a One-Stop shop. Fuse boxes, engine harnesses for use with or without electrictronic ignition, and likely lots of the parts available to repair your existing harnesses.

Cool! Thanks for the info!

cbarge

World Famous Barge in a Budget

Nothing I can add that has already been said.

I am with the others if it is not broke dont fix it.

If you are bent on rewiring, I would avoid any aftermarket generic wiring kits and go with the recommendations made too.

I have rewired many Mopars with factory or equivalent quality harnesses.

Bypass the ammeter, and bypass the main feeds of the bulkhead connector.

Repair/repkace any broken wires/connections

Make sure all grounds are clean.

You should be fine.

Hope this helps and good luck.

I am with the others if it is not broke dont fix it.

If you are bent on rewiring, I would avoid any aftermarket generic wiring kits and go with the recommendations made too.

I have rewired many Mopars with factory or equivalent quality harnesses.

Bypass the ammeter, and bypass the main feeds of the bulkhead connector.

Repair/repkace any broken wires/connections

Make sure all grounds are clean.

You should be fine.

Hope this helps and good luck.

fury fan

Old Man with a Hat

I will add a slightly differing opinion.

After experiencing an ignition-fed wire shortout in my 70 300 many years ago, and scouring the FSM to trace the wire and find the shorting location, I became disappointed in Chrysler wiring. Generally, it is reliable (it's not Lucas!) however the circuit layout didn't have a good approach to FMEA (Failure Modes Effect Analysis, which I'll get to in a minute).

I smelled the unmistakable smell, whipped a U-turn in a driveway, and high-tailed back home (about 1/2 mile). The engine stayed running because I had separate wiring to an MSD ignition, otherwise I would've been stranded. The wire was in the alternator/regulator circuitry, and it was burned from the alternator thru the bulkhead and behind the dashboard (in the vicinity of the radio). Some of it didn't burn, but the insulation and ignition switch had notable heat damage. As I traced it, I discovered the car (mostly unmolested) didn't match the FSM for this circuit, which had 4-5 different items spliced together. They were items that shouldn't have been included on the non-fused ignition circuit (was a fusible link supposed to be protecting it?). I reviewed it multiple times over several weeks and kept drawing the same conclusion.

So, to FMEA:

IIRC, the circuit included the ignition switch, voltage regulator, hot wire to the coil, and 2 or 3 other non critical items (like IP lighting, or headlight door relays, or rear window defogger, or something like that).

FMEA says to review each item for failure and understand the likelihood - and what the consequences are. The non-critical items on this circuit were likely included so they could not operate unless the ignition was on (an intentional act) and therefore prevent battery drain if the item was left on when the car was unattended. However - a short in any of those items had potential to cause the ignition circuit to fail and the engine/car immobilized. The more items, the greater potential for a short.

When I got out of school, I spent 8 years designing electrical systems for custom-built utility trucks. Learned about relays and a little about FMEA on circuits. IMO not even the VR circuit should be included with the coil feed wire - if the VR circuit fails the engine needs to stay running, even if the charging system no longer works. To design the system better would have added cost, of course, and it was a competitive market even back then.

After experiencing an ignition-fed wire shortout in my 70 300 many years ago, and scouring the FSM to trace the wire and find the shorting location, I became disappointed in Chrysler wiring. Generally, it is reliable (it's not Lucas!) however the circuit layout didn't have a good approach to FMEA (Failure Modes Effect Analysis, which I'll get to in a minute).

I smelled the unmistakable smell, whipped a U-turn in a driveway, and high-tailed back home (about 1/2 mile). The engine stayed running because I had separate wiring to an MSD ignition, otherwise I would've been stranded. The wire was in the alternator/regulator circuitry, and it was burned from the alternator thru the bulkhead and behind the dashboard (in the vicinity of the radio). Some of it didn't burn, but the insulation and ignition switch had notable heat damage. As I traced it, I discovered the car (mostly unmolested) didn't match the FSM for this circuit, which had 4-5 different items spliced together. They were items that shouldn't have been included on the non-fused ignition circuit (was a fusible link supposed to be protecting it?). I reviewed it multiple times over several weeks and kept drawing the same conclusion.

So, to FMEA:

IIRC, the circuit included the ignition switch, voltage regulator, hot wire to the coil, and 2 or 3 other non critical items (like IP lighting, or headlight door relays, or rear window defogger, or something like that).

FMEA says to review each item for failure and understand the likelihood - and what the consequences are. The non-critical items on this circuit were likely included so they could not operate unless the ignition was on (an intentional act) and therefore prevent battery drain if the item was left on when the car was unattended. However - a short in any of those items had potential to cause the ignition circuit to fail and the engine/car immobilized. The more items, the greater potential for a short.

When I got out of school, I spent 8 years designing electrical systems for custom-built utility trucks. Learned about relays and a little about FMEA on circuits. IMO not even the VR circuit should be included with the coil feed wire - if the VR circuit fails the engine needs to stay running, even if the charging system no longer works. To design the system better would have added cost, of course, and it was a competitive market even back then.

fury fan

Old Man with a Hat

So to the OP - my advice:

As others have said - don't rewire the whole car to fix what isn't broken. However, I would recommend to add robust supplementary wiring improvements that are controlled by the factory wiring, to prevent things that might become broken (some of this already mentioned):

1. Do the ammeter bypass and wire in a voltmeter (removes load/heat from the bulkhead connector).

2. Upgrade to electronic ignition (I don't see anything in your underhood picture, unless you have a Pertronix) and electronic voltage regulator - these should be fused separately from other circuits. I would recommend a 60-75 amp alternator - your rebuilt one may have that rating. (this is a general reliability improvement)

3. Consider wiring your engine's ignition system on its own relay, triggered by the ignition switch (same reason as above). This relay could be triggered by the input wire to the ballast resistor. As with the VR, should be on its own fuse. (this removes load from the ignition switch and bulkhead connector)

4. Get all of your headlights wired thru relays, triggered by the original switch via one of the original headlight connectors (this moves all of that load underhood, away from the bulkhead connector and ignition switch).

Chrysler's designs have much of the electrical load going from underhood, thru the bulkhead connector and sometimes the ignition switch - and then sometimes going back thru the bulkhead again on a different circuit. Not an efficient path! Ideally all underhood loads would be controlled by relays triggered by factory wiring.

All of the above does depend on one being able to design some robust circuits (they are simple, though) and properly execute/install them. As you work thru each step, be mindful of doing quality work and the consequences of failure of each item (FMEA!). A great relay circuit, installed poorly, is no benefit.

As others have said - don't rewire the whole car to fix what isn't broken. However, I would recommend to add robust supplementary wiring improvements that are controlled by the factory wiring, to prevent things that might become broken (some of this already mentioned):

1. Do the ammeter bypass and wire in a voltmeter (removes load/heat from the bulkhead connector).

2. Upgrade to electronic ignition (I don't see anything in your underhood picture, unless you have a Pertronix) and electronic voltage regulator - these should be fused separately from other circuits. I would recommend a 60-75 amp alternator - your rebuilt one may have that rating. (this is a general reliability improvement)

3. Consider wiring your engine's ignition system on its own relay, triggered by the ignition switch (same reason as above). This relay could be triggered by the input wire to the ballast resistor. As with the VR, should be on its own fuse. (this removes load from the ignition switch and bulkhead connector)

4. Get all of your headlights wired thru relays, triggered by the original switch via one of the original headlight connectors (this moves all of that load underhood, away from the bulkhead connector and ignition switch).

Chrysler's designs have much of the electrical load going from underhood, thru the bulkhead connector and sometimes the ignition switch - and then sometimes going back thru the bulkhead again on a different circuit. Not an efficient path! Ideally all underhood loads would be controlled by relays triggered by factory wiring.

All of the above does depend on one being able to design some robust circuits (they are simple, though) and properly execute/install them. As you work thru each step, be mindful of doing quality work and the consequences of failure of each item (FMEA!). A great relay circuit, installed poorly, is no benefit.

Excellent advice above.

Similar threads

- Replies

- 2

- Views

- 680

- Replies

- 3

- Views

- 316

- Replies

- 6

- Views

- 986