67newport

Old Man with a Hat

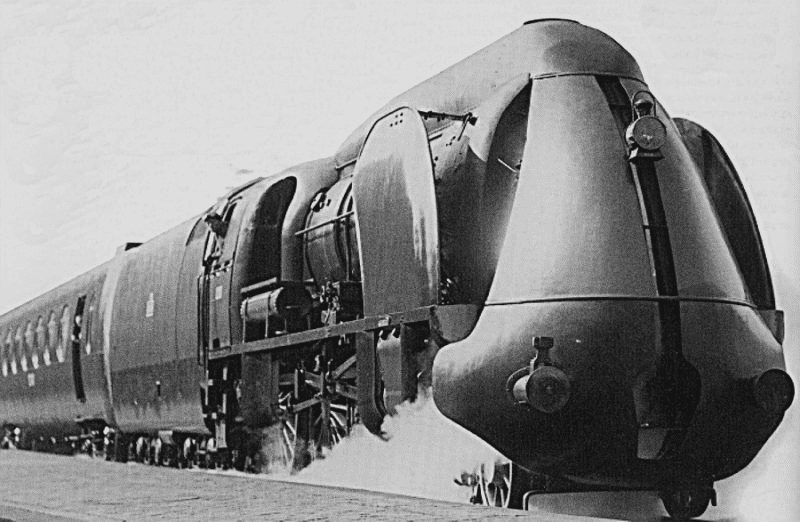

The sleek Tat 230 800 in Paris Saint-Lazare, 1937.

This pic is very interesting. Cant inspect it as it seems to be connected to an excessively spammy, prohibited, or otherwise threatening site that my browser/VPN refuses to access.

.

.

B-21s are coming to Ellsworth AFB…Hey @3175375

Stop by and tell the folks at Ellsworth to stop losing (nobody hurt thankfully) B-1's - we only have 60 left of the 100 we built.

View attachment 636846

source: B-1 bomber crashes while trying to land at its base in South Dakota, Air Force says

Taken from the web.Can anyone explain the "blow down" (IF that is what is going on) process for a steam locomotive

That's a nice photo.What you see coming out of the stack on top is a mix of the actual smoke from whatever they are burning and the steam after it exits the cylinders. Smoke will be gray or black, and the steam will be clear, but when it hits the relatively cool atmosphere starts condensing back into water and forms the white cloud. My bet is the shots with the huge fluffy white clouds were taken on a rather cold day. In most cases if the engine is being fired & run efficiently there will be little to no smoke, especially with an oil burner like the 4014. At slow speeds the steam exiting the stack will come in visible pulses that match the exhaust strokes, this is where the chug a chug sound comes from.

These days if you see a lot of dark smoke from a steam engine it is likely

a. they are doing it on purpose to make a show

b. sub optimal fuel

c. inexperienced crew.

d. they have poured some sand into the firebox to scour crud out of the boiler flues (kind of like putting seafoam down your carburetor)

Boiler blow down is definitely a thing, and while I'm not 100% sure about the Big Boy, that typically comes out down near track level towards the rear of the engine (under the firebox or cab)

What you are seeing at 13:30 (and other times) is the cylinder cocks open. You can spot this, because it will be big plumes of steam coming out sideways from near the front. Usually alternating from side to side and usually only when the engine is starting up after sitting a while. If the engine sits, the steam between the boiler and the cylinders starts to cool and condense back to liquid water. The enigineer will open the cylinder cocks for a few power strokes to clear that out. Hydrolocking a steam locomotive isn't any better than doing it to your car engine, and the broken parts are a lot bigger and heavier.

Other places you may see steam coming out:

The exhaust from the air compressors (trains have air brakes) often a small plume or puffs near the stacks, but this can vary. Different engines had the compressors located all over the place.

The whistle. Usually top of the boiler somewhere. The steam only comes out when the whistle is sounding. Cool science experiment, at a distance, you can see the plume well before you can hear it, because light travels faster than sound.

Turbogenerator. This will be a small but steady stream on top of the boiler, usually back towards the cab. Just a small steam turbine driving a generator to provide the power for the lights (and these days radios & other hi tech equipment)

Safety valves. These are on top of the boiler about halfway between the cab and the stack. If I remember correctly there are 3 or 4, each of which opens at a slightly higher pressure. The first one is set to go just over the normal max operating pressure, so it not uncommon for it to go off if the fireman has things ready to go, but the train isn't moving. You'll definitely notice this as it will make a healthy plume straight up and a loud roar.

General leaks anywhere there is a worn gasket or slightly loose fitting. Moden steam ran at 2-300 psi of steam pressure, so it doesn't take much.

View attachment 636928

Near Kenosha WI - July 26 2019.

Do NOT put your head or other body parts this close to a moving train. I started the video recording a couple of minutes in advance, propped the phone against a pole and was much farther away when the train passed.