You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My lens making thread.

- Thread starter Zymurgy

- Start date

GJS

Senior Member

Gotta say, this is some next level stuff going on here. Cheers, man!

65sporty

Old Man with a Hat

Looking really good, I am sure your next one will be spot on

bluefury361

Old Man with a Hat

Incredible effort and results Mike. Very impressive. I suppose a UV test period will be in order soon.

commando1

Old Man with a Hat

Jeezes, you guys gonna want DOT approval, too?

300rag

It's Not Going to Shift Itself

Don't need to. It's already marked on the lense.Jeezes, you guys gonna want DOT approval, too?

It took me over a decade to score a pair of near mint original lenses, I can only imagine these 66 300 owners trying to find a pair, Zymurgy could keep busy for a couple years just meeting their demand! And I don't think they will settle for anything less than perfect.

Next we want tinted -69 300 tail lensesJeezes, you guys gonna want DOT approval, too?

Addressing he UV situation, the urethane resin is a UV product made specifically for this situation and will not yellow. The resin dye has excellent color retention claims from the manufacturer, only their yellow dye does not.

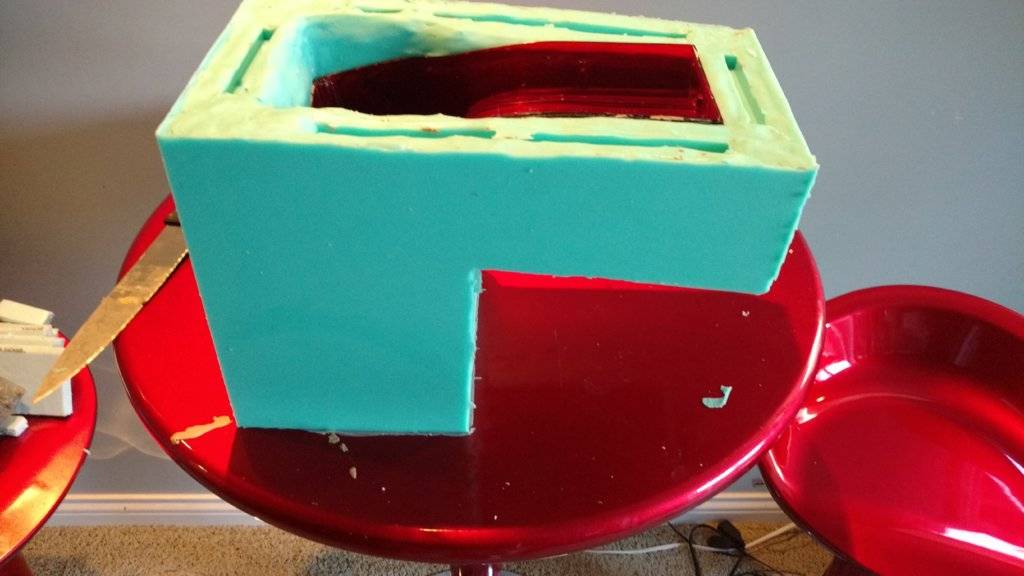

Just poured the big half of the wrap around lens. Freaking 20lbs of product. I had to do it in 2 pours to fill the box, because my intial calculation was off.

Just poured the big half of the wrap around lens. Freaking 20lbs of product. I had to do it in 2 pours to fill the box, because my intial calculation was off.

Last edited:

Next we want tinted -69 300 tail lenses

I can do that too, I have purple, blue and turquoise.

Stan got me thinking about color sample slides. The plexiglass is almost the same thickness as the lens. I made a simple open mold that I can made 8 samples.

live4theking

Old Man with a Hat

- Joined

- Nov 24, 2014

- Messages

- 12,884

- Reaction score

- 9,078

Go Mike!

By the way I did look into an accelerated UV. 10 years would cost me little under 2 Grand sorry I'm going to do it, I will take the manufacturers word for it.

And no I'm not going to get a Rabbi 2 bless it and make it kosher that would be even more expensive.

And no I'm not going to get a Rabbi 2 bless it and make it kosher that would be even more expensive.

Just send one to somebody in Arizona and have them throw it out in their yard for a couple of weeks in the summer.By the way I did look into an accelerated UV. 10 years would cost me little under 2 Grand sorry I'm going to do it, I will take the manufacturers word for it.

MarPar

Meat Man with a Hat

Paging @azblackhemi...

- Joined

- Nov 14, 2010

- Messages

- 28,555

- Reaction score

- 28,405

Incredible Mike, very impressive! As far as how they do in the uv, I would say as long these cars now spend 95% of their life in garages and under covers there shouldn’t be any issues.

Slight problem, can't seem to release Excalibur from the stone. I think 2 or 3 men could, but not my wife with no hand strength. The way the lens is made you need to pull the mold from 3 direction and 2 more hands to pull the lens out.

I slept on it and have decided to go ahead and do the second pour to complete the mold. I know I can make a small cut in the mold to remove it safely, and may need to do this just to remove the reproduced lens.

I slept on it and have decided to go ahead and do the second pour to complete the mold. I know I can make a small cut in the mold to remove it safely, and may need to do this just to remove the reproduced lens.

bluefury361

Old Man with a Hat

Perhaps a two piece mold for large items? Are you using a release agent?

I once took on reproducing the speaker grilles used in 1962/3 B body's. I hired a auto plastic prototype company in Michigan to do it. It took a few attempts to get a good mold. I got 40 OEM quality parts before the mold gave up. (They were featured in MCG). Next step was a very expensive aluminum mold.

I sold all the grilles in a short time but the cost was to high and demand to low to justify continuing.

An old mans hats off to you Mike.

I once took on reproducing the speaker grilles used in 1962/3 B body's. I hired a auto plastic prototype company in Michigan to do it. It took a few attempts to get a good mold. I got 40 OEM quality parts before the mold gave up. (They were featured in MCG). Next step was a very expensive aluminum mold.

I sold all the grilles in a short time but the cost was to high and demand to low to justify continuing.

An old mans hats off to you Mike.

Just a thought... You might have a slight vacuum holding the lens in place. Maybe a little bit of low pressure compressed air shot down the sides of the lens might break the vacuum.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 1

- Views

- 1K