badvs3vil

Active Member

Hello everyone,

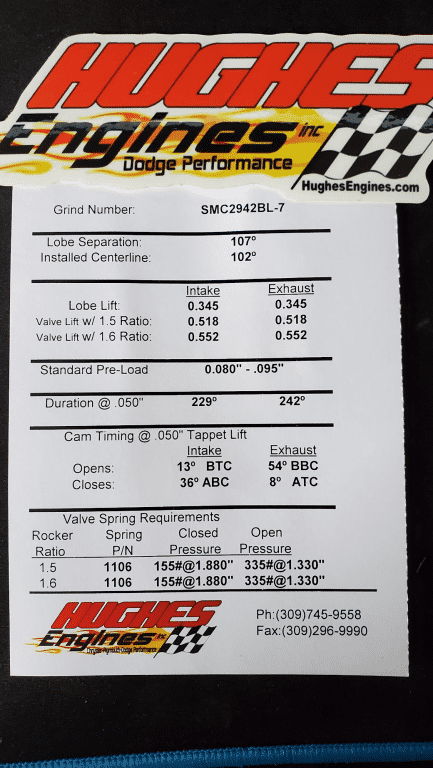

I wanted to run this by everyone who is smarter then I. My engineer rebuilder who is setting up my heads right now and installing my springs called me. Keep in mind that I got everything from Hughes for this build, the cam, springs and lifters. My engine rebuilder is questioning the spring pressure, he said 155#'s is super high for closed pressure and he thinks that I would have issues with the cam break in with that high of pressure. He said he has never seen closed pressure that high.

So I guess my question is to all of you, I assume I should still have him continue with the install as per the cam card. I also assume the Whiplash cam is made to with stand this kind of pressure?

Let me know your thoughts please.

I wanted to run this by everyone who is smarter then I. My engineer rebuilder who is setting up my heads right now and installing my springs called me. Keep in mind that I got everything from Hughes for this build, the cam, springs and lifters. My engine rebuilder is questioning the spring pressure, he said 155#'s is super high for closed pressure and he thinks that I would have issues with the cam break in with that high of pressure. He said he has never seen closed pressure that high.

So I guess my question is to all of you, I assume I should still have him continue with the install as per the cam card. I also assume the Whiplash cam is made to with stand this kind of pressure?

Let me know your thoughts please.