Beautiful weather on Tuesday. Took management for a ride.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your C-body today....

- Thread starter thrashingcows

- Start date

Samplingman

Old Man with a Hat

Disassembled and de-rusted hood number 2 for project “Pile of Rusty Metal”.

Disassembled and de-rusted hood number 2 for project “Pile of Rusty Metal”.

View attachment 618120View attachment 618121View attachment 618122View attachment 618123View attachment 618124

Jeeze. . . I didn't know you could even get a hood apart like that. Way-ta-go! Is that the final color, or are you going to paint it body-color?

Samplingman

Old Man with a Hat

Yeah, second time was easier than the first. It’s all of 20 spot welds and it splits like a clam. Currently it’s in rust converter black, once it goes back together I will paint it body color.Jeeze. . . I didn't know you could even get a hood apart like that. Way-ta-go! Is that the final color, or are you going to paint it body-color?

thrashingcows

Senior Member

Being 6'8" tall the waxing of the cars has always been hard on my back but this year I discovered how great a lift is for waxing the car! I can now just adjust the lift so I'm always working at a nice comfortable height for every panel on the car.

patrick66

Old Man with a Hat

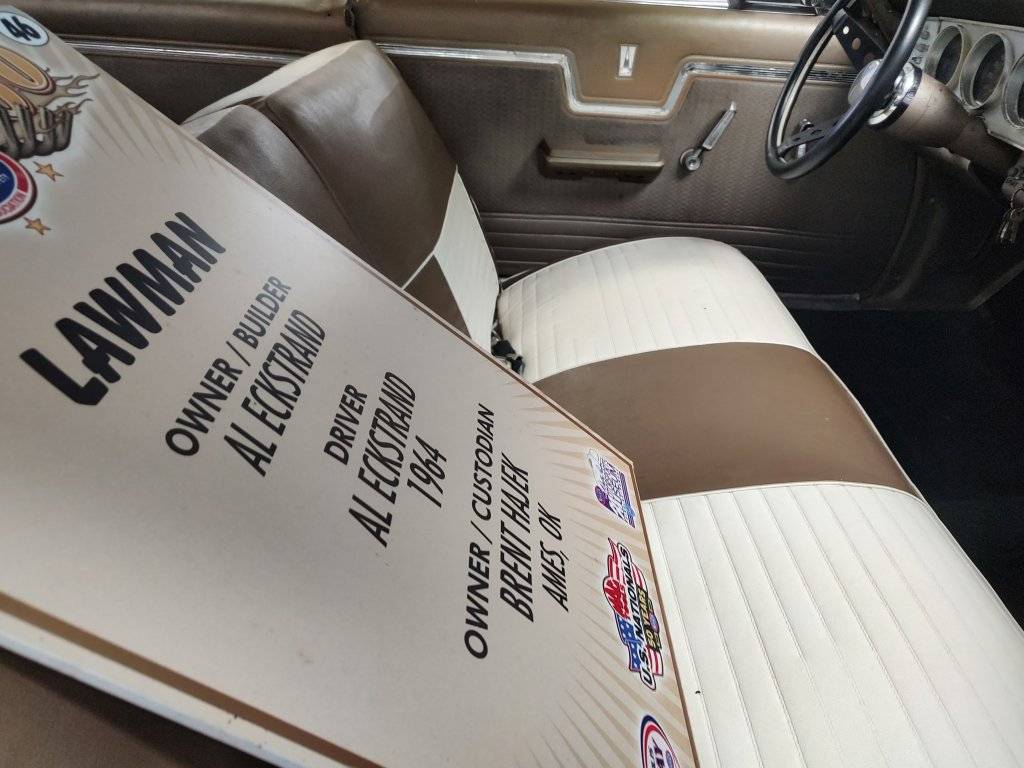

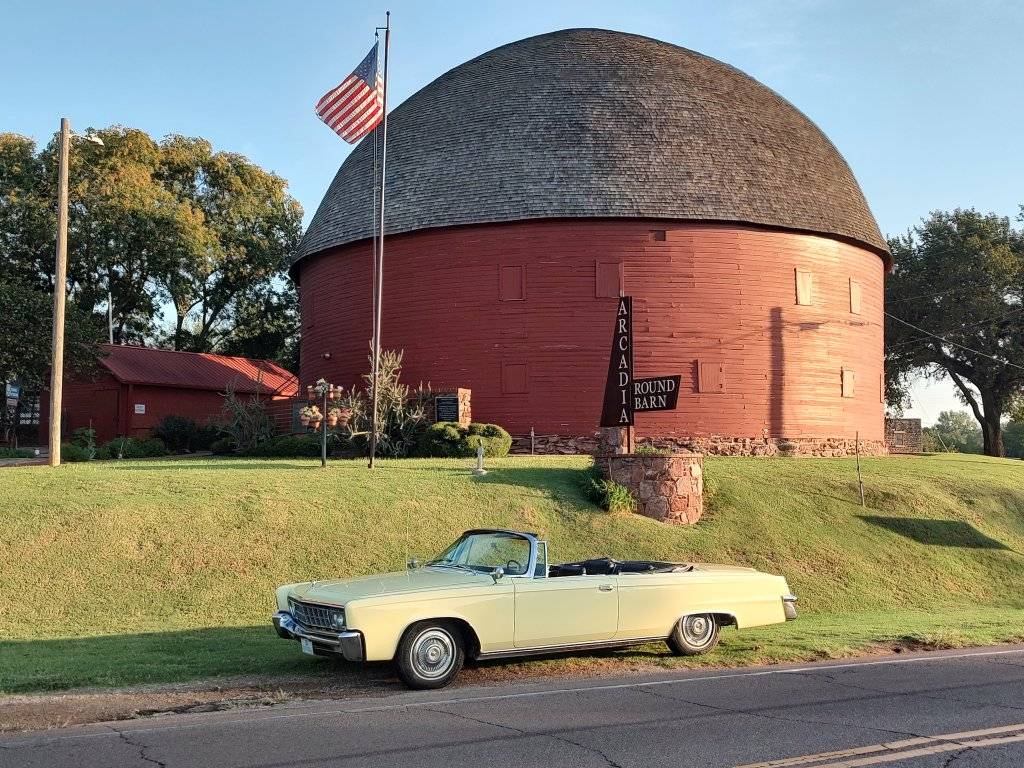

I drove the Imperial to the Hot Rod 100 run yesterday (Saturday), and had a great time. The car drove smooth and cool with the 93 octane gas I poured in the tank! I drove up with the top down going to the destination, which was Hajek Performance in Ames, Oklahoma - a 113-mile one way drive up state highways and county roads (232 miles total) The trip up was great. Until I got out of the car. I felt like I was gonna pass out, and almost straight away, started to puke. Felt like wrung-out dog **** for a few minutes! So, I got some hydration going, put the top up, and relaxed for a few before calling it a day and heading home. Pics follow of part of the amazing Hajek race car collection. His is predominantly Ford, but has a couple of Mopars and four GM cars. So impressive! I wasn't feeling like taking a bunch of pictures, unfortunately. The HRH had 135 cars participate this year!

BTW, the Imperial got just shy of 16 mpg trip average. Not bad for 5,580# with gas.

Hajek Motorsports

BTW, the Imperial got just shy of 16 mpg trip average. Not bad for 5,580# with gas.

Hajek Motorsports

Last edited:

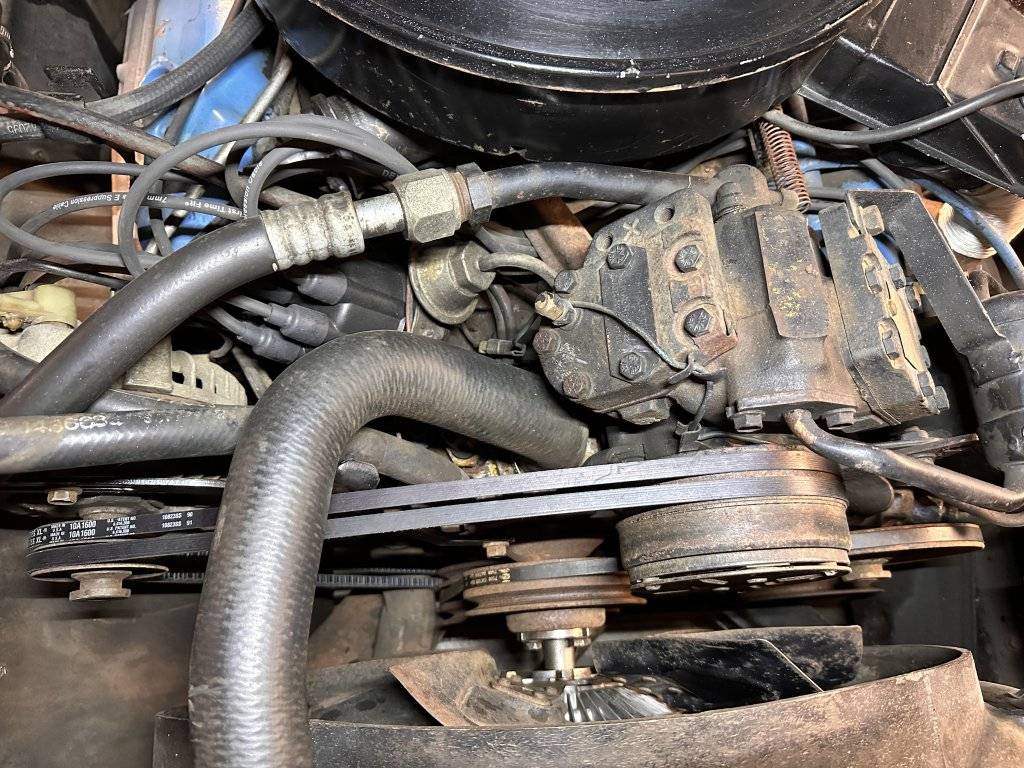

Molly and I swapped out belts and fan clutch on TB Imperial. Also did a vacuum test of heater core, we are happy to say vacuum held.

Just Carbs

Senior Member

Looked at the wiper arms on the 64 that have no rubber on them.

Owen11x

Well-Known Member

Picked up another one at impound auction. Parting it out. It's listed in parts car section if anyone needs parts.

patrick66

Old Man with a Hat

I drove my Imperial to our local COMA Mopar show! Pics at:

40th Annual COMA All-Mopar Show and Swap Meet

40th Annual COMA All-Mopar Show and Swap Meet

thethee

Senior Member

Well this kind of blew up in my face... Naturally, I wanted to see if I could find the remainder of this sheet and maybe others, so I started to remove more of the carpet and pulled the rear seats. It was bad, real bad. On both sides, the floor near the rear seat belt mount is shot to bits. Poking at it with a screwdriver yielded a massive hole.

Long story short, it's going to be a long time before this is back on the road, if ever. But always better to find this sort of thing before something bad happens.

Just Carbs

Senior Member

Replaced right rear wheel bearing and race on the 64 New Yorker. It failed because of moisture siting for many years that got past the outer bearing seal and caused corrosion at the bottom of the race resulting in a growl from the bearing.

I suspect the other side is also due. But apparently somebody wanted that drum off for brake service and didn't have a drum/hub remover. It looks like a hammer was used in some fashion to get the drum/hub of. I got the drum /hub off with my proper drum/hub remover, but probably can't get the axle shaft out with the race bearing and seal because the threads on that side are in such bad shape now from the hammer damage. I did clean/flush out the bearing and then got ample amounts of grease in it with a syringe. Then I just put it back together and welded the axle nut on for now.

It now needs another axle shaft. But another rear from a later model with a 3.23 or 3.55 gear will show up first.

Got a pair of axle shafts with bearings and ready to go from a 68 to replace the tapered shafts on the 64. One of the 64 shafts was damaged, from a hammer.

Samplingman

Old Man with a Hat

Hood redux ready for installation.

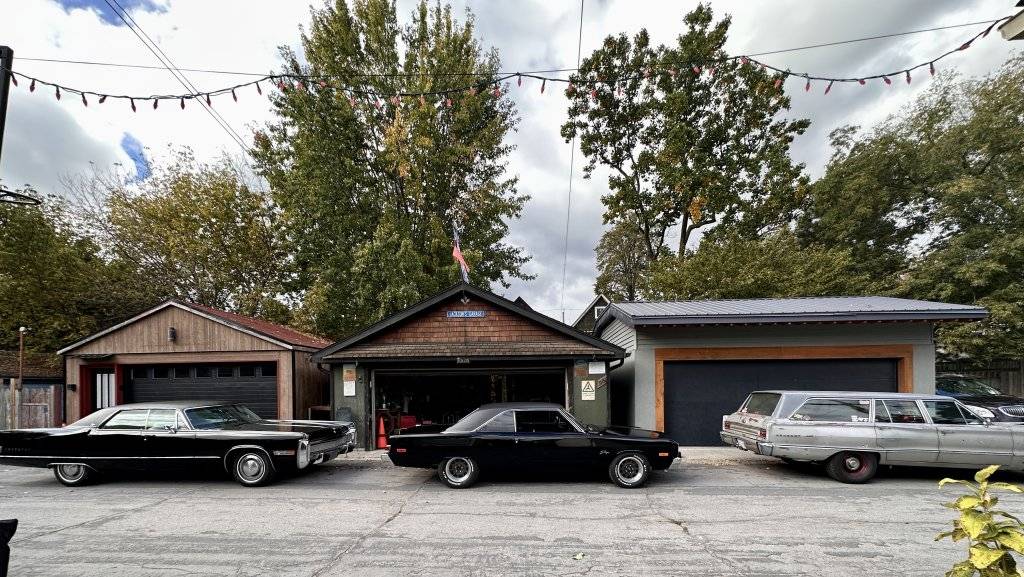

On Thursday I took TB to park out of the way until new owner finally picks TB up. (Uuuugghhh) Brought my Swinger home to run some fuel through her lines after sitting for too long. On Saturday I moved the fleet around, put the wagon in the garage where I need to retrieve tools and supplies often. As I not so worried about the wagons paint and whats left of it. Tux was moved into my work garage for safer rest and some cleaning and the Swinger went to a garage down the lane for out of the way but close enough to use spot. Then we had our big Thanksgiving dinner. Happy Thanksgiving.

Got the radiator re-cored for the 300L.

It's hard to find a good shop that will do this. I found a guy about 45 minutes north of here... He's 74 and works out of his little garage next to his house.

Came out nice! The bottom tank only allows for a 2 row core, but the new cores have different spacing that allows more rows.

The shop that worked on this years ago for the former owner lost the soldered on number tag... So if anyone has a number tag with 2524986 on it that they'd part with, let me know.

It's hard to find a good shop that will do this. I found a guy about 45 minutes north of here... He's 74 and works out of his little garage next to his house.

Came out nice! The bottom tank only allows for a 2 row core, but the new cores have different spacing that allows more rows.

The shop that worked on this years ago for the former owner lost the soldered on number tag... So if anyone has a number tag with 2524986 on it that they'd part with, let me know.

carguy300

Senior Member

I got motor in the 300 ready to clean up, cleaning valve, timing chain covers. Getting ready for painting and reassembly when new parts arrive sometime this week.

I wanted to install seat belts in the rear seat of my 300L. Gotta have them for the grandkids.

I pulled the seat bottom and discovered the foam had hardened and turned to dust... So that meant a bit more work.

Rear floor covered in foam dust.

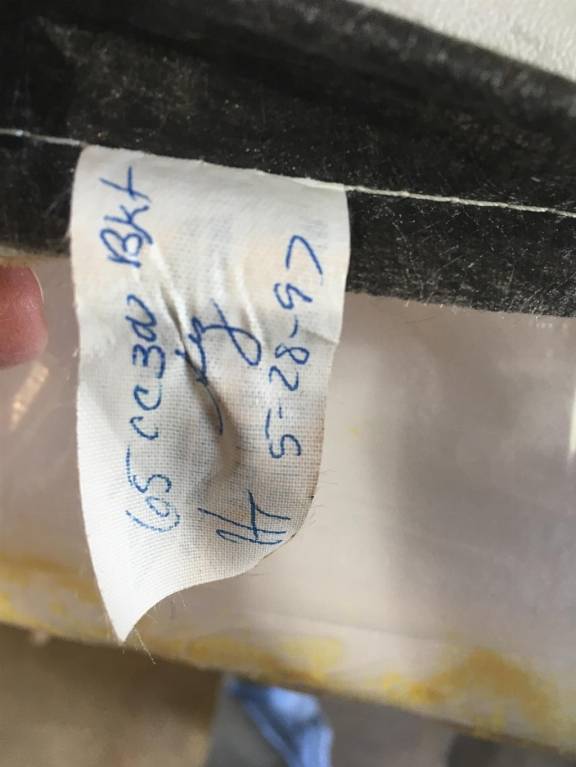

A tag shows this is a Legendary cover made in 1997!

Foam was so dry it crumbled.

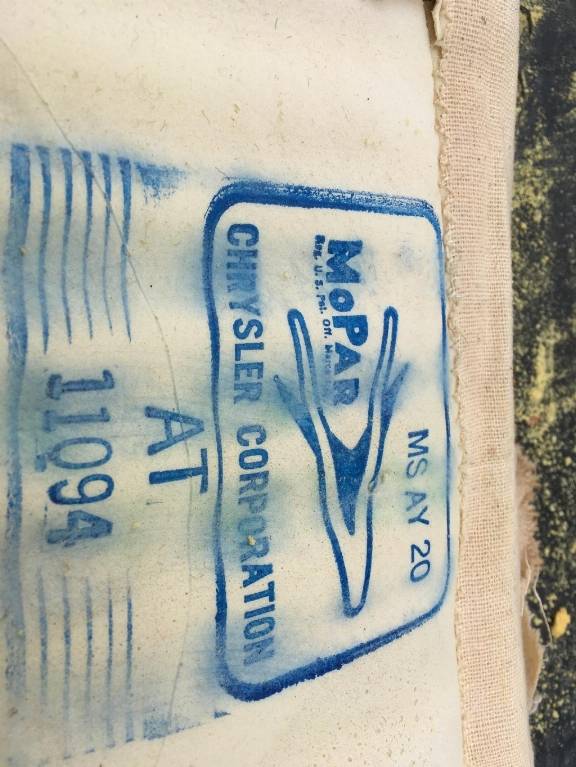

And interesting that it had a Forward Look logo.

Burlap was bad too.

New burlap with the metal stays inserted. That was a PITA.

I forgot to take a pic of the new foam. I used some 1" 44lb high density foam I got from Amazon.

I like to do this when it's warm out, but 55 degrees was the best it's going to get for a while. With the cold and a used cover, it was really tough to get the bottom of the cover down far enough to clip it with the hog rings. I can't remember where I saw this trick, but it works nice... You use zip-ties to pull everything down and stretch the cover. Push and tighten until the cover is in place and you can use the hog rings to secure it.

Finished... Came out OK.. I think if the cover was new, and stretched easier, I could have done a little better, but it's good. Still have to do the seat belts!

I pulled the seat bottom and discovered the foam had hardened and turned to dust... So that meant a bit more work.

Rear floor covered in foam dust.

A tag shows this is a Legendary cover made in 1997!

Foam was so dry it crumbled.

And interesting that it had a Forward Look logo.

Burlap was bad too.

New burlap with the metal stays inserted. That was a PITA.

I forgot to take a pic of the new foam. I used some 1" 44lb high density foam I got from Amazon.

I like to do this when it's warm out, but 55 degrees was the best it's going to get for a while. With the cold and a used cover, it was really tough to get the bottom of the cover down far enough to clip it with the hog rings. I can't remember where I saw this trick, but it works nice... You use zip-ties to pull everything down and stretch the cover. Push and tighten until the cover is in place and you can use the hog rings to secure it.

Finished... Came out OK.. I think if the cover was new, and stretched easier, I could have done a little better, but it's good. Still have to do the seat belts!

Just got back from taking to mother-in-law and wife to Burt Lake in the northern lower peninsula for a week. Stayed a week. Trip was made in the 'Party Barge' 600 mile round trip. MPG was between 14-15 using 89 octane,

Used 1 qt of oil on the way up (apparently the 'Barge' objects to sustained cruising at 85-90 mph keeping up with traffic).

A couple of hiccups; the turn signal switch became loose which made signaling a hit-or-miss affair. It also resulted with intermittent horn-blowing. The second was one of the high beams quit working. Also, as this was the first time any night -time driving was involved, The head lights were badly aimed.

The trip home was uneventful. Cruising was a more moderate 75-80 with no oil consumption. The loose turn-signal switch was tightened which also fixed the horn issue. The high bean turned out to be a bad ground in the new head light relay wiring, and the headlight aiming was accomplished when I repaired my 'Hoppy' headlight aimers (bad 'O' rings).

This weekend will be the last trip of the year with the 'Barge'. Going to Columbus Oh (2 1/2 hours south) for a weeding. The 'Barge' may even be in it.

Used 1 qt of oil on the way up (apparently the 'Barge' objects to sustained cruising at 85-90 mph keeping up with traffic).

A couple of hiccups; the turn signal switch became loose which made signaling a hit-or-miss affair. It also resulted with intermittent horn-blowing. The second was one of the high beams quit working. Also, as this was the first time any night -time driving was involved, The head lights were badly aimed.

The trip home was uneventful. Cruising was a more moderate 75-80 with no oil consumption. The loose turn-signal switch was tightened which also fixed the horn issue. The high bean turned out to be a bad ground in the new head light relay wiring, and the headlight aiming was accomplished when I repaired my 'Hoppy' headlight aimers (bad 'O' rings).

This weekend will be the last trip of the year with the 'Barge'. Going to Columbus Oh (2 1/2 hours south) for a weeding. The 'Barge' may even be in it.

carguy300

Senior Member

Looks pretty dang good to me!I wanted to install seat belts in the rear seat of my 300L. Gotta have them for the grandkids.

I pulled the seat bottom and discovered the foam had hardened and turned to dust... So that meant a bit more work.

Rear floor covered in foam dust.

View attachment 621718

A tag shows this is a Legendary cover made in 1997!

View attachment 621719

Foam was so dry it crumbled.

View attachment 621720

And interesting that it had a Forward Look logo.

View attachment 621721

Burlap was bad too.

View attachment 621722

New burlap with the metal stays inserted. That was a PITA.

View attachment 621723

I forgot to take a pic of the new foam. I used some 1" 44lb high density foam I got from Amazon.

I like to do this when it's warm out, but 55 degrees was the best it's going to get for a while. With the cold and a used cover, it was really tough to get the bottom of the cover down far enough to clip it with the hog rings. I can't remember where I saw this trick, but it works nice... You use zip-ties to pull everything down and stretch the cover. Push and tighten until the cover is in place and you can use the hog rings to secure it.

View attachment 621724

Finished... Came out OK.. I think if the cover was new, and stretched easier, I could have done a little better, but it's good. Still have to do the seat belts!

View attachment 621725

Similar threads

- Replies

- 11

- Views

- 3K

- Replies

- 3

- Views

- 1K

- Replies

- 2

- Views

- 1K