A couple of my Road Wheel centers have stripped threads. You can usually give the center a turn and use some alternate holes, but some ham fisted tire changer in the car's past made sure that wasn't going to happen. So... A repair was needed.

Typical stripped hole.

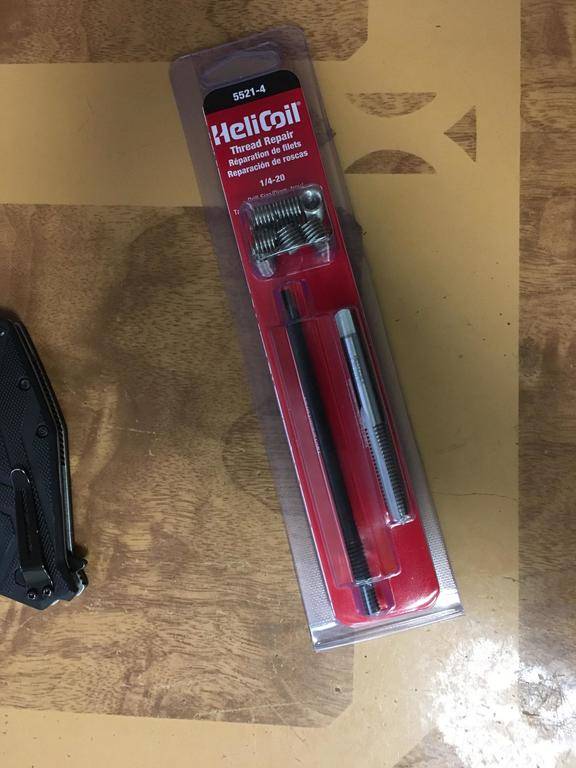

First, you'll need a Heli-Coil kit. The threads are 1/4-20.

https://smile.amazon.com/gp/product/B0002SRE8Q/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

Included in the kit is the special Heli-Coil tap, an inserting tool and 12 heli-coils.

You'll need some drills, tap wrench, small punch, small hammer, and an electric drill. A countersink bit, like shown is nice but not a must.

I used my trusty Craftsman hand drill. Having a variable speed and easy reversibility is handy.

The proper size tap drill is a 17/64".

Because of the type of material, I first used a 15/64", then a 1/4" and then finished with the 17/64". The material that they cast the wheel centers from will tend to grab the drill so you want to "sneak up" on it to get the hole drilled to size.

Typical stripped hole.

First, you'll need a Heli-Coil kit. The threads are 1/4-20.

https://smile.amazon.com/gp/product/B0002SRE8Q/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

Included in the kit is the special Heli-Coil tap, an inserting tool and 12 heli-coils.

You'll need some drills, tap wrench, small punch, small hammer, and an electric drill. A countersink bit, like shown is nice but not a must.

I used my trusty Craftsman hand drill. Having a variable speed and easy reversibility is handy.

The proper size tap drill is a 17/64".

Because of the type of material, I first used a 15/64", then a 1/4" and then finished with the 17/64". The material that they cast the wheel centers from will tend to grab the drill so you want to "sneak up" on it to get the hole drilled to size.