Bigasawhale2

Member

- Joined

- Jan 25, 2014

- Messages

- 66

- Reaction score

- 54

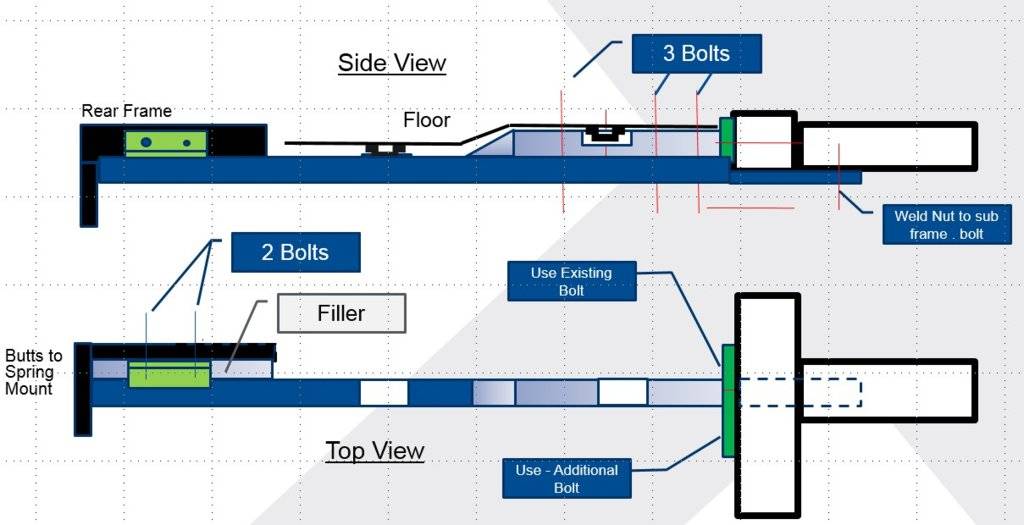

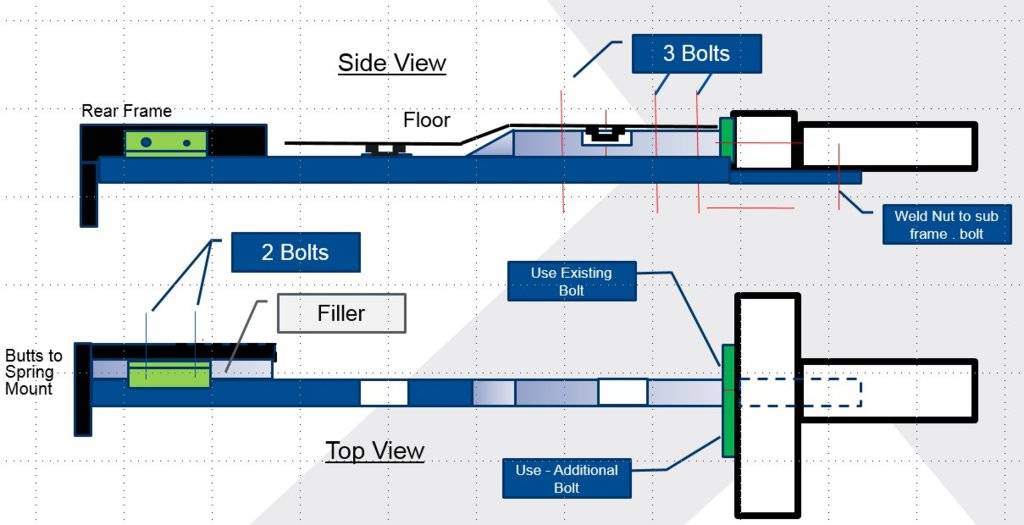

I used many of the threads on this site, as inspiration for my version of sub frame connectors.

My Goal(s)

Stiffen the car, used the connectors to lift the car if needed

Use and Maintain the factory bolt location in the sub frame

Once all is proven to work well - a couple of strategic welds, in the back frame rails

Share, to the C Body community

My Goal(s)

Stiffen the car, used the connectors to lift the car if needed

Use and Maintain the factory bolt location in the sub frame

Once all is proven to work well - a couple of strategic welds, in the back frame rails

Share, to the C Body community

Last edited: