Took the Nimitz in for some work on the rear brakes (been banging on application figured the adjuster was out of sorts). Also I’ve been noticing some excess slop in the steering and some uneven tire wear.

So....

Up on the alignment rack/lift she goes...

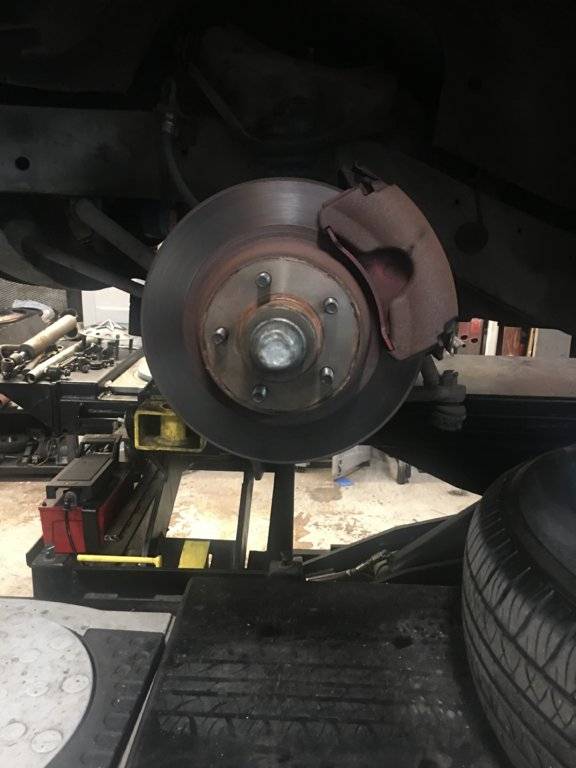

Sure enough... adjuster cable is slack and adjuster is stuck (both sides). Shoes look good though. Take it appart, clean it up, lubricate the adjuster and see if that does it.

Front pads all good.

Front tires wearing on the inside. Check alignment, set camber, check the upper and lower control arm bushings after new tire rods are in. If all good, reset the alignment.

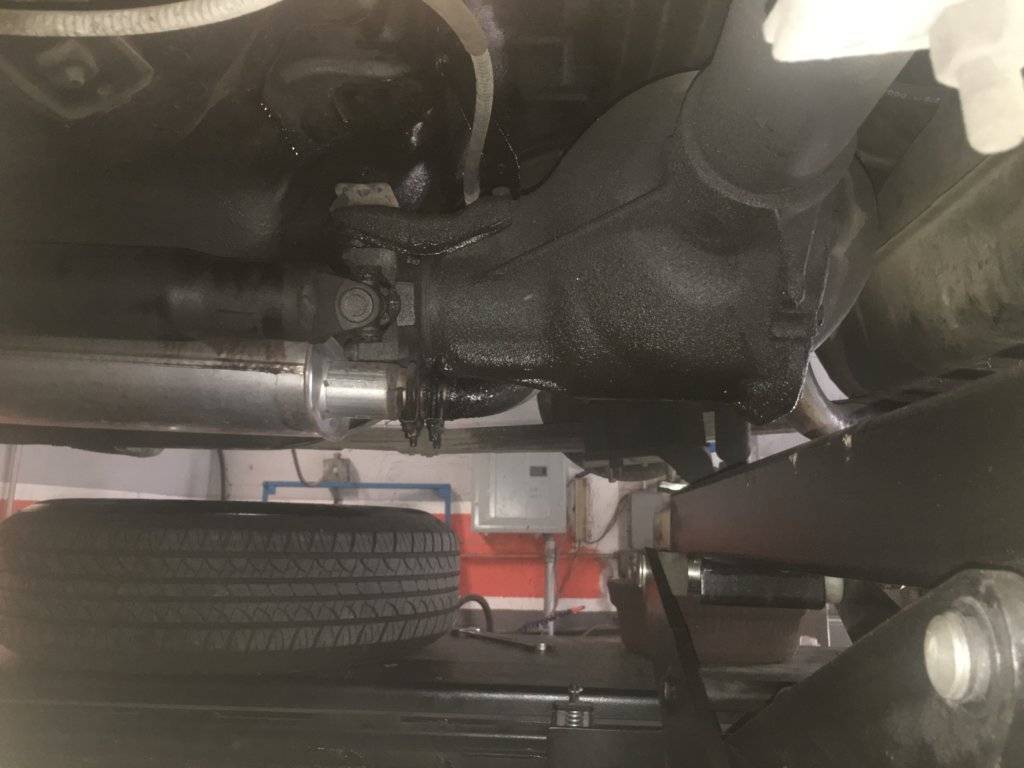

The front tire rods are all varying degrees of “toast”. As is idler arm. No wonder it felt so sloppy. Interesting is that it didn’t pull and the wheel held straight.

Going to have to look up how to change the pinion oil seal. Leaking.

Shocks all leaking too... will start rear self-leveling project on this excuse.

Been a year on the road since recommissioning her.

She’ll be down for a few days. Will miss the killer A/C.... good thing that it’s finally starting to get less hot!

So....

Up on the alignment rack/lift she goes...

Sure enough... adjuster cable is slack and adjuster is stuck (both sides). Shoes look good though. Take it appart, clean it up, lubricate the adjuster and see if that does it.

Front pads all good.

Front tires wearing on the inside. Check alignment, set camber, check the upper and lower control arm bushings after new tire rods are in. If all good, reset the alignment.

The front tire rods are all varying degrees of “toast”. As is idler arm. No wonder it felt so sloppy. Interesting is that it didn’t pull and the wheel held straight.

Going to have to look up how to change the pinion oil seal. Leaking.

Shocks all leaking too... will start rear self-leveling project on this excuse.

Been a year on the road since recommissioning her.

She’ll be down for a few days. Will miss the killer A/C.... good thing that it’s finally starting to get less hot!

Last edited: