Metalmarty

Member

Hi all,

Couple of questions.

My matching numbers 383 is disassembled and needs a lot of work for rebuilding. I'm thinking of dropping in another engine to be able to drive while I'm rebuilding my 383.

383 are really hard to get over here (in the Netherlands).

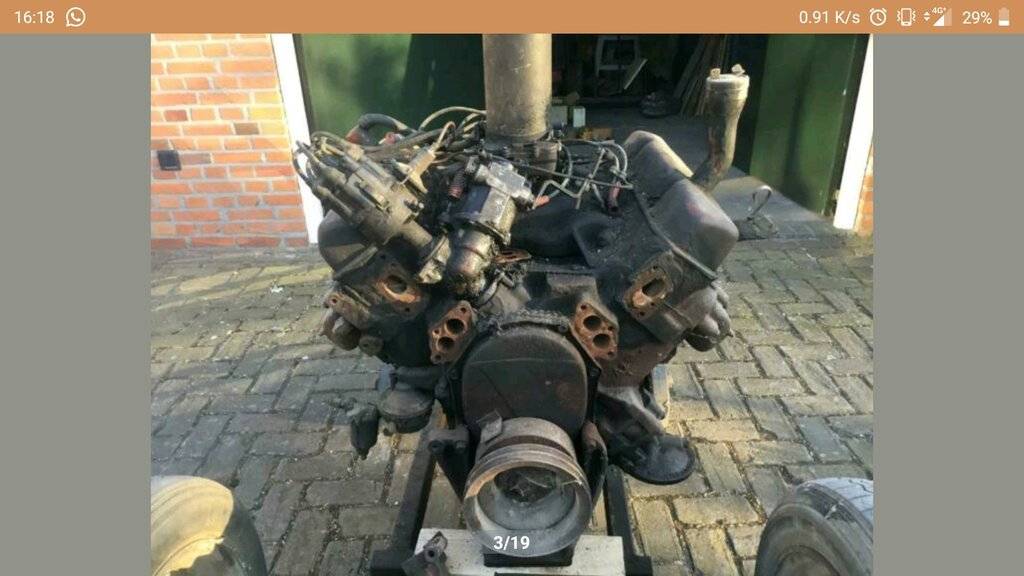

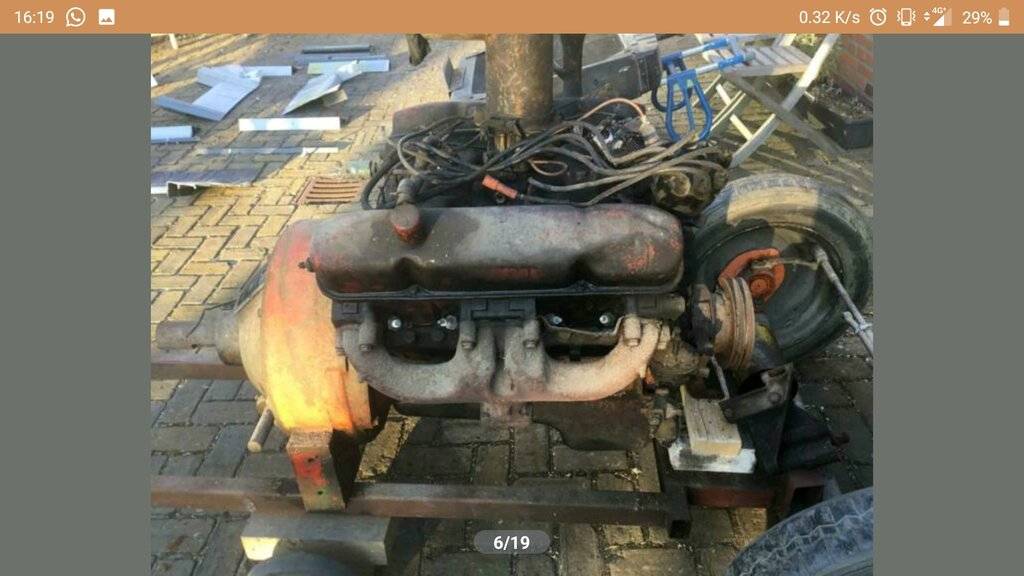

I came across a 361 industrial engine.

Would this engine fit on my big block 727, motormounts, waterpump, distributor etc etc?

In other words is that engine a drop in replacement?

Couple of questions.

My matching numbers 383 is disassembled and needs a lot of work for rebuilding. I'm thinking of dropping in another engine to be able to drive while I'm rebuilding my 383.

383 are really hard to get over here (in the Netherlands).

I came across a 361 industrial engine.

Would this engine fit on my big block 727, motormounts, waterpump, distributor etc etc?

In other words is that engine a drop in replacement?