You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'66 Monaco Resto-Mod

- Thread starter Jack-Stand

- Start date

Jack-Stand

Active Member

I wish I could say there’s a scientific approach to cleaning it up, but I’d be lying if I did. It was basically just grabbing a Handful of wire, making sure it’s all tight/straight, rinse and repeat.That first picture of wiring is where I get overwhelmed and give in.

Mr C

Senior Member

Although this is not my bag (Ha! Get it?) Them's some fine welds & skills there!

I have the same welder and my welds look like rat turds...

I have the same welder and my welds look like rat turds...

Jack-Stand

Active Member

Haha Keep the dad jokes coming, I’m building my Arsenal. My poor kids are done for.Although this is not my bag (Ha! Get it?) Them's some fine welds & skills there!

I have the same welder and my welds look like rat turds...

Thank you much! As much as I’d like to claim credit, I give the credit to my grandfather (farmer) and all the other machinists/fabricators that took the time to cultivate the mess that is me.

TxDon

Well-Known Member

That wiring job is great! Be careful when fitting your seat cushions...

So once all the systems are fitted in and functioning, are you removing it all to detail and paint? Or are you going for the patina look with the surprise of modern function? Either way is cool, just curious. It's a lot of work you're doing so I figure you're engineering things in your build to be "serviceable" - in that assemblies and wiring can be removed fairly easily if things need to be repaired or modified.

Jack-Stand

Active Member

Thank you much! It was an awful lot of work for something that no one is going to see. After looking through the old harness a time or two, I'm definitely glad I completely redid everything. The old harness was in ROUGH shape. As far as the seat cushions go, everything clears, but the seat "rests" on the bottom of the bench (technically a bucket-bench) are close enough to the wiring that I may modify the cage. I need to do some more test fitting before I completely go down that road though.That wiring job is great! Be careful when fitting your seat cushions...

Honestly I haven't quite decided if I'm going to pull the harness or leave it in. This is going to sound kind of silly, but as it stands, the wires that are terminated at the circuit board aren't labeled. I did however label/name the junction blocks in such a way that they're easily labeled with an electrician's sticker book (just haven't put mine to use yet). The good news is that if I do decide to pull it, it'd be relatively easy to pull it in one shot. The body mounts that hold the wire up to the car are the flat-tab type that use a zip tie to lash the bundle to it. The basic design of the car is to effectively have "stock" functionality (added accessories of course), with the reliability of modern relays. I can't remember if I mentioned this in a previous post before, but everything still retains its functionality. The rear brake lights are still "interrupted" by the turn signal, and everything from the "brights" indicator on the dash, to the fender mounted turn signal indicators. It's just that everything is now driven by relays.So once all the systems are fitted in and functioning, are you removing it all to detail and paint? Or are you going for the patina look with the surprise of modern function? Either way is cool, just curious. It's a lot of work you're doing so I figure you're engineering things in your build to be "serviceable" - in that assemblies and wiring can be removed fairly easily if things need to be repaired or modified.

mr. fix it

Old Man with a Hat

Wiring looks great cleaned up.

It's always a challenge to keep a tidy wiring system.

It's always a challenge to keep a tidy wiring system.

Jack-Stand

Active Member

Thanks! Next step is going to be putting it all in wire loom to clean it up/protect it further. I halfway hate to hide all the wiring, but I really don’t want to do through the effort required to clean up and detail the trunk tunnel. As a joke, I told one of my buddies that I thought about making my tank panel/mount out of plexiglass. Then I priced plexiglass of ample thickness.Wiring looks great cleaned up.

It's always a challenge to keep a tidy wiring system.

rags

Senior Member

it'd be neat to use the signal from that to control the variable steering.I'll be able to use the speed pickup that's stock to the ford 8.8 rear end.

Mr C

Senior Member

Haha Keep the dad jokes coming, I’m building my Arsenal. My poor kids are done for.

Thank you much! As much as I’d like to claim credit, I give the credit to my grandfather (farmer) and all the other machinists/fabricators that took the time to cultivate the mess that is me.Are you burning flux core, or gas? The biggest thing I’ve noticed with my welder is that if it doesn’t have ample input current, the output stinks, and I can never get it to buzz. I ran a dedicated110V, 20A outlet specifically so that I had good input current.

Flux core...I don't weld enough to justify gas. I confess that I was very pleased with the welds I got when I replaced the dog leg on my M body.

Jack-Stand

Active Member

I looked into it and honestly it wasn’t that bad, the issue was the cost. A new Ford VSS module is upwards of $500, and even my local junkyard wanted $200 for a pull out. I chatted with a couple buddies who do electronics/controls, and the biggest hurdle was going to be converting the sinusoidal input signal of the speed sensor into a constant DC output. It was doable, but the costs basically took me right back up to the $200 mark. I opted for a $15 cheapo instead. lolit'd be neat to use the signal from that to control the variable steering.

Flux core can be really tough just because it burns so hot. I’ve got a 10lb spool that I keep on the shelf for when I need to fuse something thick, other than that I run gas. Once you buy a bottle, you never go back unless you absolutely have to. My Buddy said the same thing about his TIG machine. lol I’d love to have one, but I couldn’t ever justify the expense.Flux core...I don't weld enough to justify gas. I confess that I was very pleased with the welds I got when I replaced the dog leg on my M body.

patrick66

Old Man with a Hat

Impressive work! Anytime I work on wiring, I manage to let the smoke out of the wires.

Jack-Stand

Active Member

Haha I had a seasoned electrical engineer tell me once that all electronics/anything electrical are nothing more than smoke containment devices. The wires are the pipes that carry the smoke and the other stuff just converts the stuff to action. Sad part is, he wasn’t kiddingImpressive work! Anytime I work on wiring, I manage to let the smoke out of the wires.

Jack-Stand

Active Member

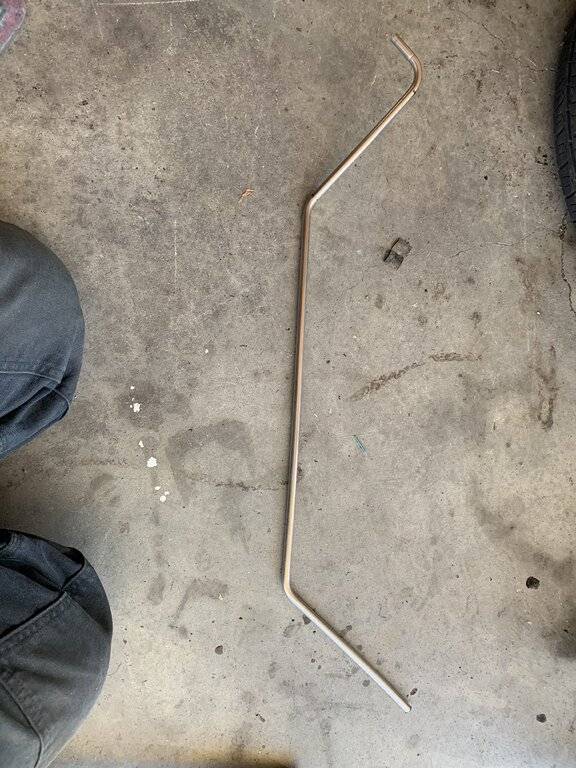

Kind of got a last hoorah before I go into my busy season at work. We’re about to try to do a generator overhaul between thanksgiving and Christmas, so I’ll be living at work (my poor bride and little ones aren’t too pleased). Either way, got a decent amount accomplished. I managed to bend/route the stainless fuel feed and return lines. Much like my air lines to the bags and my solenoids, I grabbed a scrap piece of stainless tube and bent a “sacrificial” piece to match my firewall before I started bending the main lines. The connection from them to the EFI and to the rank will be AN fittings on the end of rubber hose. I also got the interior back in the car (just to see what it looks like all together), I got the entire suspension completely tuned/aligned, and I was able to put the entire air system through its system checks. The center console still isn’t very pretty, but it was neat to see everything in place.

Jack-Stand

Active Member

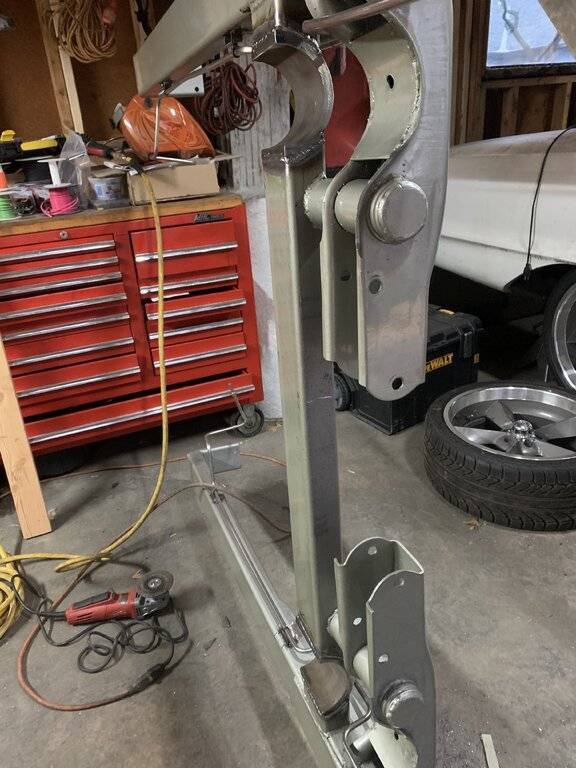

Finished these up a while ago, but didn't get the chance to post them because work's been nuts. Since I added a cross member to the subframe of the car, I had to figure out how I was going to clear the exhaust pipes (since the car sits on the ground). Lo and behold, a piece of 5", 0.500" wall DOM makes for really good exhaust reliefs. The install was pretty straight forward, and honestly the hardest part was getting the subframe out from under and back under the car.

3175375

Old Man with a Hat

Very nice work!Finished these up a while ago, but didn't get the chance to post them because work's been nuts. Since I added a cross member to the subframe of the car, I had to figure out how I was going to clear the exhaust pipes (since the car sits on the ground). Lo and behold, a piece of 5", 0.500" wall DOM makes for really good exhaust reliefs. The install was pretty straight forward, and honestly the hardest part was getting the subframe out from under and back under the car.

View attachment 441616 View attachment 441617 View attachment 441618 View attachment 441619 View attachment 441621 View attachment 441622 View attachment 441623

View attachment 441620

Are you concerned about the fuel line running as close to the exhaust as is shown on inside the subframe rail? It appears to be close.

Jack-Stand

Active Member

Those are actually the air lines that feed the front bags. The pictures kind of make it look confusing because those air lines kind of mimic the original fuel line routing. My fuel lines actually hug the bottom of the unibody, and are basically mounted to the floorboard. They still be somewhat close to the exhaust, but Hopefully it won’t get to warm. I’ll be running an electric fuel pump and EFI, so vapor locking shouldn’t be an issue, but I’d be lying if I said I wasn’ta little concerned about the heat.Very nice work!

Are you concerned about the fuel line running as close to the exhaust as is shown on inside the subframe rail? It appears to be close.

patrick66

Old Man with a Hat

I like how your console blends into the rear seat like it does. Nice and smooth.

All that fancy metalwork, and I see the console. LOL!

All that fancy metalwork, and I see the console. LOL!

good golly

New Member

You are one gifted individual. That is some very nice work.

Similar threads

- Replies

- 7

- Views

- 3K

- Replies

- 10

- Views

- 2K