It was interesting task, and a bit of a challenge, but I am very happy with the results!

I did the drivers side first, I removed retainers and bent tabs up to remove chrome trim surround - then removing the vinyl from the foam went fairly easy. The tabs for the 300 emblem were broken, and it was epoxied to the vinyl only! I remedied that by using two # 10 - 32 thread 1/2 machine screws - I ground the heads till perfectly flat, then epoxied them to the flat surfaces on the back of the emblem, and drilled two holes in the door panel to line it up - then used two washers and nuts to secure after the new vinyl was installed.

I had to re-glue the foam down first - this is the culprit for all the 68 door pad woes = loose foam from door panels ! I used the old Vinyl as a template to cut out new pieces -I applied the contact cement to the foam and new vinyl in thirds - not all at once = this allowed me to form the hole for the emblem to sit it - I did end up making some pie cuts in the very center of the hole to allow it to form good definition around the perimeter . After stretching the last bit of vinyl and tucking it under the top of the door chrome, I reinstalled the pad surround trim, and installed the emblem!

I eventually ended up fabricating and replacing the foam on the passenger side, using some 1/2" high density foam but it came out really nice. I had to carefully shave the back side of the new foam to replicate the thinner foam at the top of the original pad = but it was pretty straight forward.... I would actually recommend using the new foam, as the glue spreads and grabs better

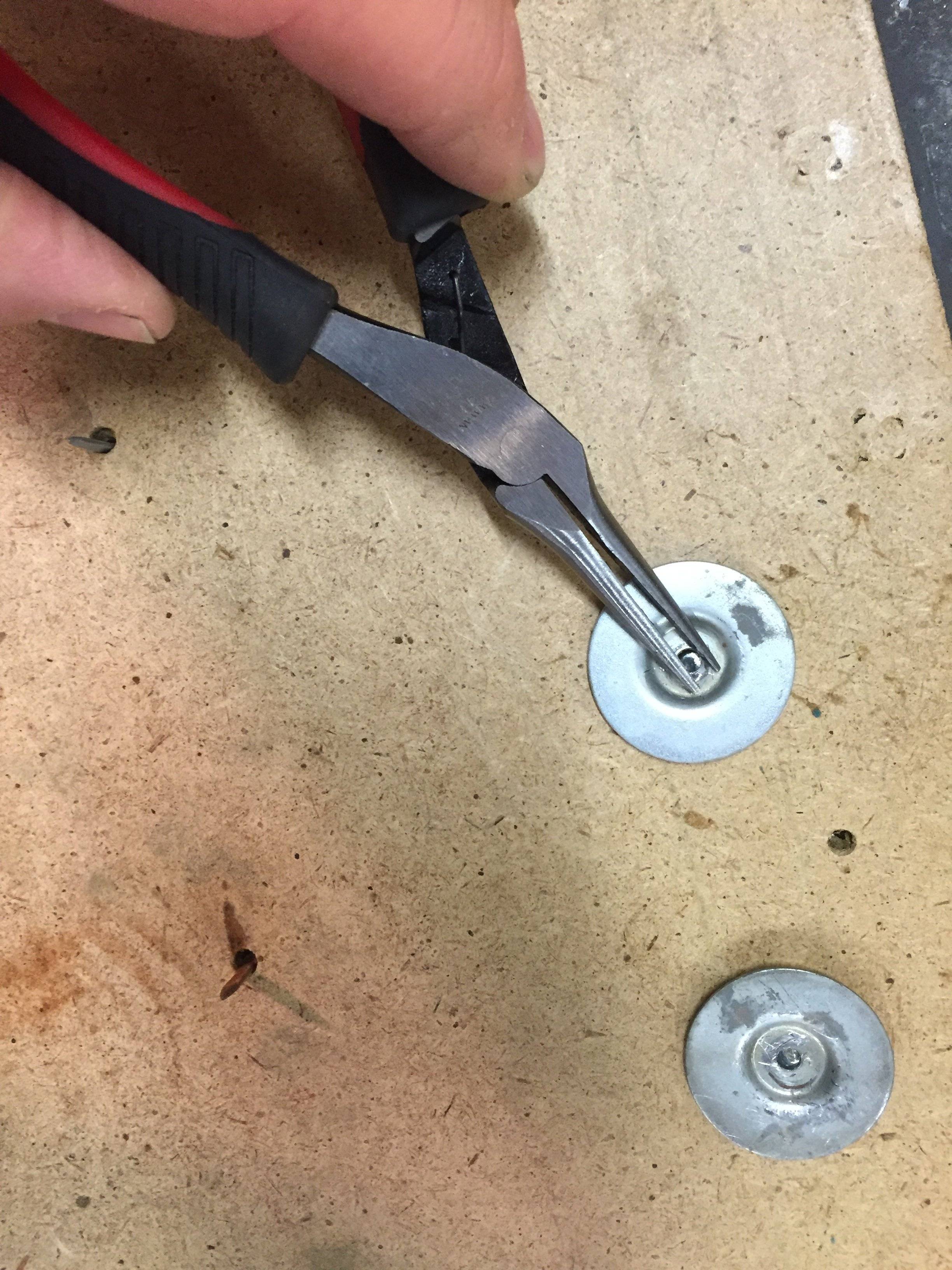

The posts for the passenger side emblem were in perfect condition, - so I just used some pliers to remove the "swedge", then reused them and employed epoxy to create new swedge upon re-installation

As for the carpet = that was very simple = remove chrome trim, with a sharp exacto knife carefully cut the threads from the carpet around the bottom and side perimeters = remove the old carpet with a putty knife use the old piece for a template to cut new carpet. Then secure to the door panel with contact cement, replace the trim and I used a commercial grade carpet seam tape (non heated) I cut 1/4 ' strips and reattached the surrounding vinyl to the carpet ( in place of the sewn in threads) it grabs very good, and it appears it should hold up well Here are some in process pics , and some final results !!

I did the drivers side first, I removed retainers and bent tabs up to remove chrome trim surround - then removing the vinyl from the foam went fairly easy. The tabs for the 300 emblem were broken, and it was epoxied to the vinyl only! I remedied that by using two # 10 - 32 thread 1/2 machine screws - I ground the heads till perfectly flat, then epoxied them to the flat surfaces on the back of the emblem, and drilled two holes in the door panel to line it up - then used two washers and nuts to secure after the new vinyl was installed.

I had to re-glue the foam down first - this is the culprit for all the 68 door pad woes = loose foam from door panels ! I used the old Vinyl as a template to cut out new pieces -I applied the contact cement to the foam and new vinyl in thirds - not all at once = this allowed me to form the hole for the emblem to sit it - I did end up making some pie cuts in the very center of the hole to allow it to form good definition around the perimeter . After stretching the last bit of vinyl and tucking it under the top of the door chrome, I reinstalled the pad surround trim, and installed the emblem!

I eventually ended up fabricating and replacing the foam on the passenger side, using some 1/2" high density foam but it came out really nice. I had to carefully shave the back side of the new foam to replicate the thinner foam at the top of the original pad = but it was pretty straight forward.... I would actually recommend using the new foam, as the glue spreads and grabs better

The posts for the passenger side emblem were in perfect condition, - so I just used some pliers to remove the "swedge", then reused them and employed epoxy to create new swedge upon re-installation

As for the carpet = that was very simple = remove chrome trim, with a sharp exacto knife carefully cut the threads from the carpet around the bottom and side perimeters = remove the old carpet with a putty knife use the old piece for a template to cut new carpet. Then secure to the door panel with contact cement, replace the trim and I used a commercial grade carpet seam tape (non heated) I cut 1/4 ' strips and reattached the surrounding vinyl to the carpet ( in place of the sewn in threads) it grabs very good, and it appears it should hold up well Here are some in process pics , and some final results !!