Hi guys,

i have a Chrysler 300 1966 and i recently fixed the horn ... so i had to pull down the steering wheel.

Since that i noticed that my steering wheel wobbles and found out that the shaft is not fixed (anymore).

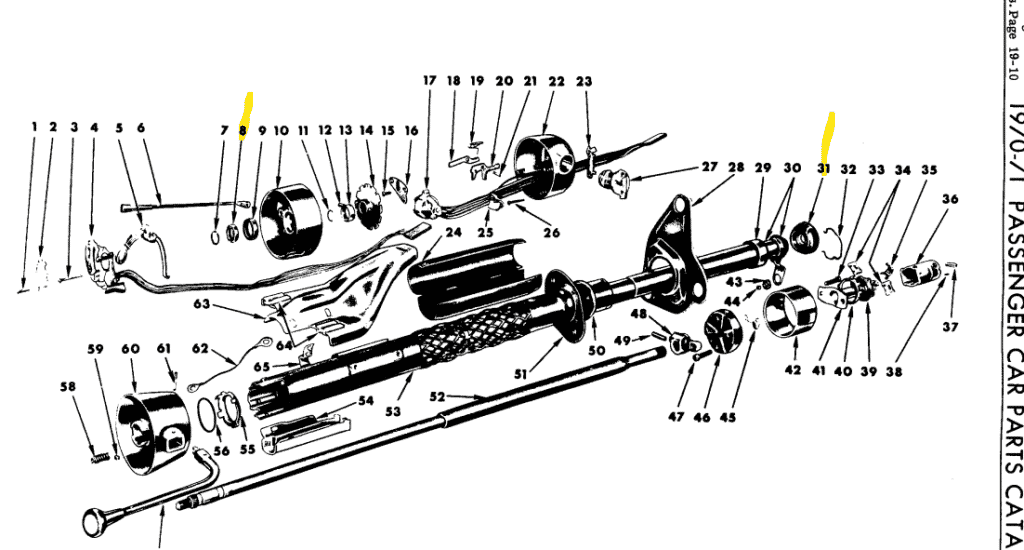

I found some plans here where there is a snap ring mentioned but there was none the time i remove the steering wheel.

Anyone an idea what happed?

I have the tilt and telescopic steering.

i have a Chrysler 300 1966 and i recently fixed the horn ... so i had to pull down the steering wheel.

Since that i noticed that my steering wheel wobbles and found out that the shaft is not fixed (anymore).

I found some plans here where there is a snap ring mentioned but there was none the time i remove the steering wheel.

Anyone an idea what happed?

I have the tilt and telescopic steering.