The Horvaths

Young man with a cowboy hat

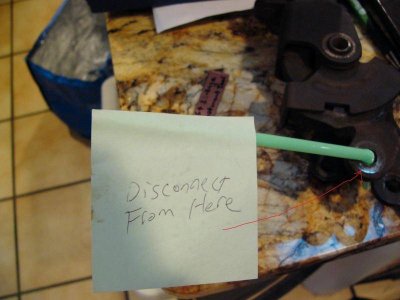

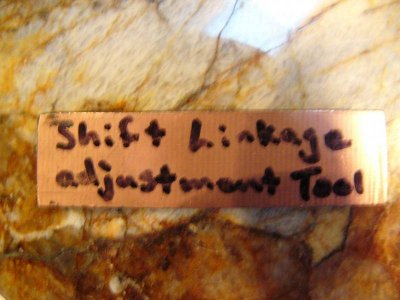

So, to start this thread off, I will begin with the shifter.

The original shifter to the car had a popped weld and a few fractures, so we decided it would be best to just get a new one (pictured above).

It is the same Inland Shifter that came with the car.

We took the new shifter, and put it in an ultrasonic parts washer for about an hour. Then we put it in the oven to dry quickly. It cleaned it up really well!

The next step, was to remove the shifter handle so it would not be damaged. Also, it is important that you replace the grommets where the handle mounts! The grommets for the Sport Fury are different than those from B-Bodies!

The original shifter to the car had a popped weld and a few fractures, so we decided it would be best to just get a new one (pictured above).

It is the same Inland Shifter that came with the car.

We took the new shifter, and put it in an ultrasonic parts washer for about an hour. Then we put it in the oven to dry quickly. It cleaned it up really well!

The next step, was to remove the shifter handle so it would not be damaged. Also, it is important that you replace the grommets where the handle mounts! The grommets for the Sport Fury are different than those from B-Bodies!