Damn man that's looking clean! I followed Mattrods thread and was inspired by it, but I didn't want to do all that work or even pay somebody to do it! There had to be a better or more practical way. Up front, the shock tower was removed and replaced with a 8" hydraulic cylinder. It fits right in there and bolted right to the LCA( I had a professional shop do it). All of the bump stops were removed and any other item that would keep me from laying crossmember. The rear, Im still running 2 leaf springs and 3" blocks. The hydros were mounted to the side of the frame and down to the axle. I may have it rebuilt with a bridge connecting the two frame rails and having the cylinders mounted there and down to the axle. I have 4 batteries, 2 pumps and 4 accumulators for the smooth ride. They do not disappoint. It's not a hopper or a hot rod race car. It's strictly for laying out and just being low. I don't get crazy with the switches because these are uni-bodied cars and you don't want to start twisting things up! If you're looking to put power to the pavement, I'd definitely look into a 4-link set up to take any of the torque off of the hydros.

Yeah getting all that work paid for would be insane .... I really wish he finished that car; madness fab skills!!

Couple questions for ya 440Sled:

front

1) so your torsion bars are hooked up still? just turned basically all the way down? are the torsion bar bolts dangerously close to scraping the ground?

2) how are your ball joints? any binding issues or are you not close to that range yet layin cross member?

3) have you found any need for shocks? or are the accumulators doing their job? did they actually break in and soften up a bit or is that all BS?

back

1) did you have to notch the crossmember where the original shocks were mounted for the pumpkin to tuck up?

2) If you didnt tunnel the floor how much would the drive shaft stop you from layin out?

It's been fun! Going on 3 years now with no issues. I charge the batteries about every 3 months or so. Your car is 100x's nicer than mine, plus your looking burn some rubber. Some reinforcements would definitely be needed!

I'm "Chris68" on the Los Boulevardos forum.

Thank you very much!!

and yeah I was on LB and recognized your car! ... tried to go through the build thread you got on there with the suspension .... but I cant view the pics since I'm not registered ... ANNNND I they are not taking registration any longer ..... so ****. (But its all good I found the info I needed .... I was just interested!!)

I have the welder that that one gave birth to and I love it although I find I don't use the "auto set" feature as I did when I first got it. It has infinite settings in addition to the "auto set". It's one hell of a machine that plugs into a 110 volt outlet!

yeah that 110V is beautiful!!! go anywhere with it!!!

--------------------

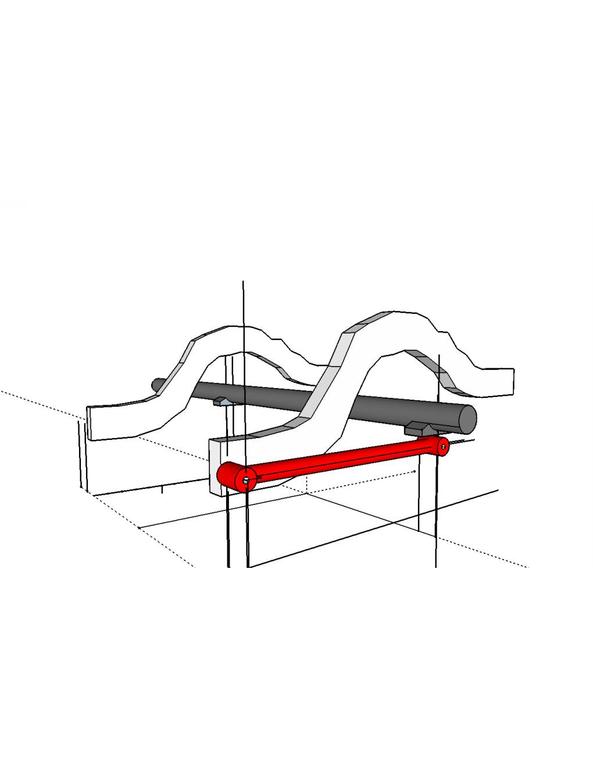

So with all this suspension talk I dove into 4 link set ups .... Annnnnnd theres no kits for C-bodies (as is tradition ... not surprised at all)

so I dove into custom design .... which doesn't look to hard. I'll take advantage of the Front spring mount and go from there with the top mount.

I found this crazy calculator for a base line at least! this guy put in some serious work!

http://www.pirate4x4.com/forum/gene...-version-my-4-link-analyzer-request-help.html

The only similar car was this '67 fury from New Zealand with a decent 4 link set up and bagged at the back (No compressor or anything ... just bags as the springs)

I think it may be the right route to go ... then if I want to go any further with the suspension I can always just upgrade this setup (for juice or whatnot)

If anyone has a link to a build with bar lengths etc .... let me know!!

Because this is what my U-bolts etc look like right now .... pretty damn close to bottoming out .... and I just rebuilt my driveshaft (sweet jesus I had no idea what I was getting into ... the ******* thing has 4 U-Joints .... and they were stuck in there so damn hard .... I bent my hydraulic press trying to get them out) So I'm really not keen on doing it again if I get to much axle wrap.....

see how close those bolts are to the wheel dolly? nervous.

Got into the rear bumper this weekend .... Still need one side bumperette rechrome .... going out next week prob. I have near perfect lenses and trim peices for the bumper which is nice!!

Had to start off with removing some broken bolts ....

Then I got it on the car and realized I have made a brutal mistake ... the bottom line of the quarter panel was never right and is sitting about a half inch lower that where it should come to on the bumper .... should have / could have / would have mounted the bumper in the right spot before I started ..... now I have to rework that panel ... fuckin' pissed me right off ....

This is about where it should come too

this is the side I already finished ....