The cylinder heads on a '72 440 motorhome engine are very unique! All unto themselves! How? The exhausts are all separate ports, not next to each other in the middle. The intake side looks like normal B/RB ports, so a normal RB intake will fit. The '72 440 MH engine used a Holley 4160, just like a normal Chrysler-spec Holley carb for a car.

The combustion chambers look more like a LA motor, rather than the wedge-shape of a B/RB engine. Which makes things more unusual, for the heads. Intake like a B/RB, combustion chamber shaped like a LA, exhaust ports like a Chevy 454.

My machine shop operative had one of these motors brought to him for a rebuild, back in the 1980s. The owner also brought the Holley off of it for a rebuild. First time I'd ever seen those heads. I checked the Holley part number in the Holley Variable Spec Manual and it matched a "1972 Chrysler 440 Motor Home Chassis" application.

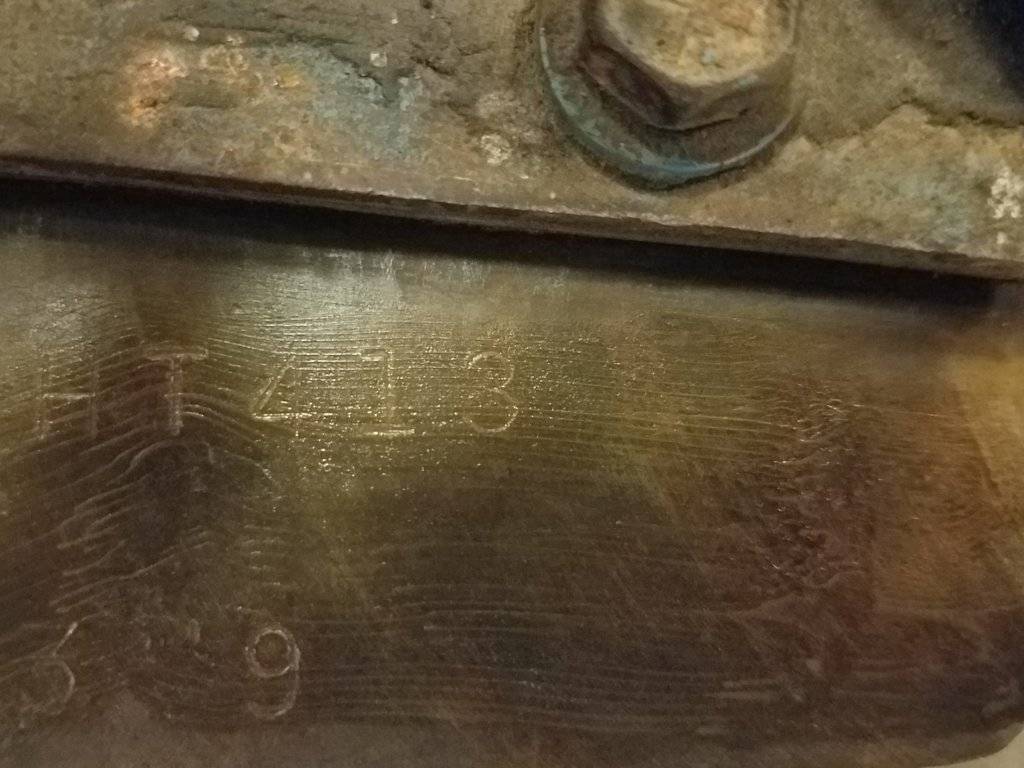

As far as the "unknown" 413 goes, my observation is that the main power increase for the 440 over the 413 came from a better cam, possibly larger carb cfm, and better exhaust manifolds (larger cross section of the "log"). No reason that a 413 upgraded with later 440 intake, cam, 906 heads (with the 1.74" exhaust valves), and later model exhaust manifolds shouldn't make similar power as a similar 440 would.

Chrysler pistons and pins are more than 1000gms EACH. Lighter pistons will surely help the "zingability" of the motor, especially when combined with lighter/stronger connecting rods. As mentioned, such things will need to have the rotating assembly balanced. "Knife-edging" of the crank counterweights might be done at that time, too?

When Chevy used the 4-ring pistons in the 366 and 427 truck engines, they also raised the deck height of those engines, in comparison to the normal big block Chevy engines. This allowed the same length rods and such to be used, as the taller piston was compensated for by the taller deck, rather than a different pin location in the piston. That higher deck made them desirable for racing stroker motors in the 468 and 486cid range.

440 MHC blocks also had the "hour glass" shape water passage on the deck of the block. Many perceive that this was for greater water flow in the HD applications and loads the engines would see, BUT when the head gasket was installed, it covered that area with the normal water restriction hole, so no greater amount of water flow could occur. More of a visual ID for the block than anything else.

A local dirt contractor had one or two of the MD Dodge dump trucks in their fleet. When I looked at one in the shop, I wondered "Why" on the different water pump configuration. "Weird" was more operative, as I recall. Nobody had any parts, so almost everybody who had one of those trucks chunked it when they needed serious repairs. In '74, Frontier Dodge in Lubbock had two of them sitting on the lot. I suspect they were sold for pure cost, just to sell them.

Be sure to check/record the casting numbers and dates on the block, heads, etc. . . . for general principles. Plus the distributor number, if it's still got one.

CBODY67