I broke in my 383 stroker today. Everything went really good as far as i know, primed it, fired it up and ran it for 25 mins at 2300-3000 rpm. Water temp good, 180-210, no thermostat with box fan in front of radiator, used just water and burped it. She sounded great. As soon as she fired up I set timing without vacuum at 35, only issue i have is that a 35 degrees all in, the vacuum port on the distributor is right up against the radiator hose. See pictures. Do I spin it 180? TIA.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Distributor vacuum port touching radiator hose.

- Thread starter jake

- Start date

Spinning it 180 degrees won't help.

There's one of two solutions. The easy one is you move every wire two places clockwise and move the distributor counterclockwise. You won't have to remove the distributor to do this. Best is to have the engine at TDC and point the rotor to #1 before you start, and clock it to the new #1. Then retime after it starts.

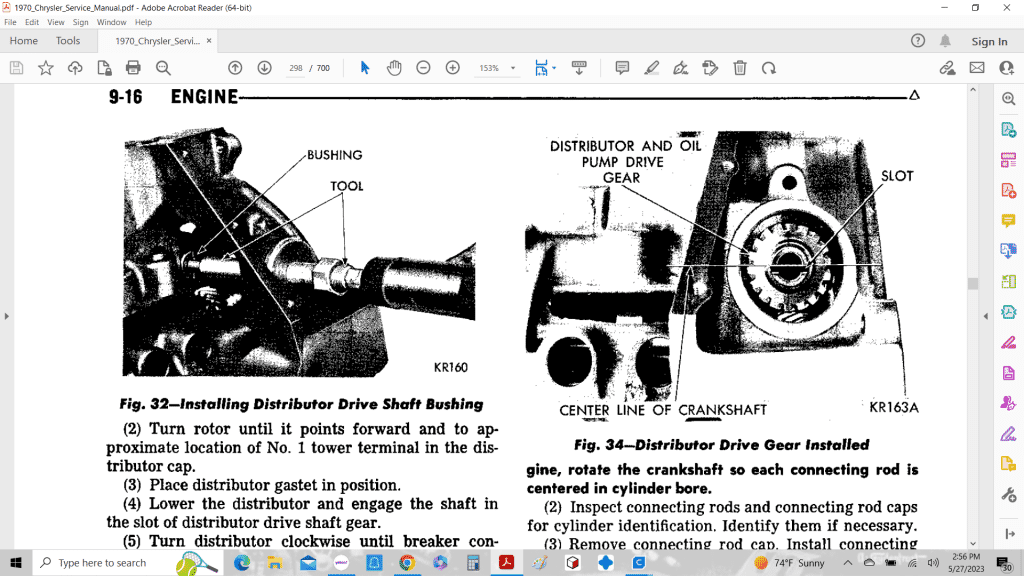

The other is you pull the distributor and check the orientation of the slot in the drive. If you look in the FSM, there's a picture of where it should point. Distributor goes back in and with the engine at TDC on the compression stroke, clock the distributor where you want it, and where the rotor points is your #1. Orient the plug wires (18435672 counterclockwise) and retime.

There's one of two solutions. The easy one is you move every wire two places clockwise and move the distributor counterclockwise. You won't have to remove the distributor to do this. Best is to have the engine at TDC and point the rotor to #1 before you start, and clock it to the new #1. Then retime after it starts.

The other is you pull the distributor and check the orientation of the slot in the drive. If you look in the FSM, there's a picture of where it should point. Distributor goes back in and with the engine at TDC on the compression stroke, clock the distributor where you want it, and where the rotor points is your #1. Orient the plug wires (18435672 counterclockwise) and retime.

This is where the drive gear should point at TDC. Honestly, this is the way I would do it, but it does take more fooling around.

I used this method not too long ago and worked great once back together. What big john forgot to mention is that oil pump/distributor drive gear can be a bit frustrating and tricky if you have to pull it to orient the slot different for any reason. Have a few different styles of really long needle nose type pliers handy to figure out which ones work best for you to pull the gear up enough to turn it. If you have to remove that gear may need a long oil pump priming shaft tool to change the orientation where the bottom of the shaft drops into the oil pump which is a hex shape. Sounds complicated but with the right tools ahead of time its not too bad and the best way to fix your issue.This is where the drive gear should point at TDC. Honestly, this is the way I would do it, but it does take more fooling around.

View attachment 599039

The best way I've found to move that distributor is to take a big screwdriver and stick it in the slot and rotate it so it climbs up out of the cam gear. Turn and push in. Might take a couple tries to get it right, but that works for me.I used this method not too long ago and worked great once back together. What big john forgot to mention is that oil pump/distributor drive gear can be a bit frustrating and tricky if you have to pull it to orient the slot different for any reason. Have a few different styles of really long needle nose type pliers handy to figure out which ones work best for you to pull the gear up enough to turn it. If you have to remove that gear may need a long oil pump priming shaft tool to change the orientation where the bottom of the shaft drops into the oil pump which is a hex shape. Sounds complicated but with the right tools ahead of time its not too bad and the best way to fix your issue.

Rather than a big screwdriver, might a angled-end tire iron (as comes with the jack in the trunk) work, too? I used that on one engine I put a camshaft in. Getting the distributor to clock in at the correct oil pump position was troubling. So I used the tire iron to turn the oil pump shaft before inserting the distributor. Not on a Chrysler engine, fwiw. In any event, easy to see how much you turn the shaft with that bent handle.The best way I've found to move that distributor is to take a big screwdriver and stick it in the slot and rotate it so it climbs up out of the cam gear. Turn and push in. Might take a couple tries to get it right, but that works for me.

Just some thougths,

CBODY67

I use that giant screwdriver that came in my Craftsman tool set I bought 50 years ago. You know, the one that you really only use as a pry bar...Rather than a big screwdriver, might a angled-end tire iron (as comes with the jack in the trunk) work, too? I used that on one engine I put a camshaft in. Getting the distributor to clock in at the correct oil pump position was troubling. So I used the tire iron to turn the oil pump shaft before inserting the distributor. Not on a Chrysler engine, fwiw. In any event, easy to see how much you turn the shaft with that bent handle.

Just some thougths,

CBODY67

I WANT ONE OF THOSE IN THE PIC, JUST BECAUSE!I use that giant screwdriver that came in my Craftsman tool set I bought 50 years ago. You know, the one that you really only use as a pry bar...

View attachment 599040

I WANT ONE OF THOSE IN THE PIC, JUST BECAUSE!

jimmyessbee

Member

Is there a reason to not just move all of the plug wires a couple of spaces down?

MrMoparCHP

Old Man with a Hat

Another vote for rotating the distributor about the distance of 1 plug and move all the plug wires.

Your advance is in the general direction it should be.

Alan

Your advance is in the general direction it should be.

Alan

Similar threads

- Replies

- 8

- Views

- 7K

- Replies

- 14

- Views

- 2K

- Replies

- 5

- Views

- 3K