saylor

Senior Member

the madness continues.

ever since i bought my car in 2013, the temperature was not right. when i got it, the PO had a pusher electric fan rigged up to a manual on/off switch under the dash. one of the first things I uninstalled. also the PO was running it with no thermostat.

I have since changed coolant, replaced all the hoses, proper tstat + cap, new overflow bottle and hose, etc. the car does OK, but in traffic, in TX, in the summer time, it gets to the edge of hot, like 210 ish, and i start getting nervous hoping for the light to change.

so i was looking at summit for a new pusher fan, and found the thermocure rust o snake oil crap. and bought that. and was going to do a writeup about that.

so THEN the other day I was out at the car, draining the rad and filling with the snake oil, and got to looking at the shroud. its not the correct shroud :/ i never really paid attention to it until the other day. it overs the whole fan blade width, is smushed flat on the bottom to fit in, and is about 2" to wide a circle for the fan diameter. WTF. And the shroud that is there now is about 3/4" from flush, and is only about 90% coverage, about an inch or radiator hangs out past the shroud edge.

that changed everything - I need a proper fan shroud, and my hot issue would probably go away.

summit to the rescue! - at $150, and you have to wrastle the thing in to place. BAH.

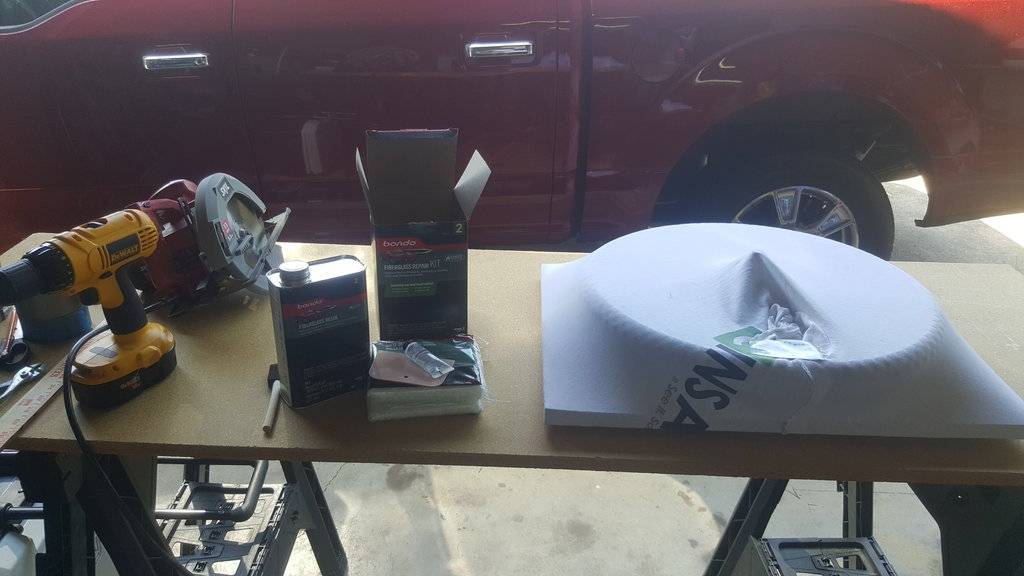

so, I figured it is time to learn how to fiberglass

I took a bunch of measurements and ended up at 24 1/4" x 17 3/4" radiator inside seam. center of fan is 8 14" down from inside seam. Fan is somewhere very near 17 3/4" diameter. from backside face of radiator to farthest edge of fan blade 4".

so the form I made is 24"x17 1/4" x 4" - the 4" is the round part, which I will cut to 3 1/2" at the end of the project.

ever since i bought my car in 2013, the temperature was not right. when i got it, the PO had a pusher electric fan rigged up to a manual on/off switch under the dash. one of the first things I uninstalled. also the PO was running it with no thermostat.

I have since changed coolant, replaced all the hoses, proper tstat + cap, new overflow bottle and hose, etc. the car does OK, but in traffic, in TX, in the summer time, it gets to the edge of hot, like 210 ish, and i start getting nervous hoping for the light to change.

so i was looking at summit for a new pusher fan, and found the thermocure rust o snake oil crap. and bought that. and was going to do a writeup about that.

so THEN the other day I was out at the car, draining the rad and filling with the snake oil, and got to looking at the shroud. its not the correct shroud :/ i never really paid attention to it until the other day. it overs the whole fan blade width, is smushed flat on the bottom to fit in, and is about 2" to wide a circle for the fan diameter. WTF. And the shroud that is there now is about 3/4" from flush, and is only about 90% coverage, about an inch or radiator hangs out past the shroud edge.

that changed everything - I need a proper fan shroud, and my hot issue would probably go away.

summit to the rescue! - at $150, and you have to wrastle the thing in to place. BAH.

so, I figured it is time to learn how to fiberglass

I took a bunch of measurements and ended up at 24 1/4" x 17 3/4" radiator inside seam. center of fan is 8 14" down from inside seam. Fan is somewhere very near 17 3/4" diameter. from backside face of radiator to farthest edge of fan blade 4".

so the form I made is 24"x17 1/4" x 4" - the 4" is the round part, which I will cut to 3 1/2" at the end of the project.

Last edited: