You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FBO Ignition upgrade

- Thread starter 70_NPORT

- Start date

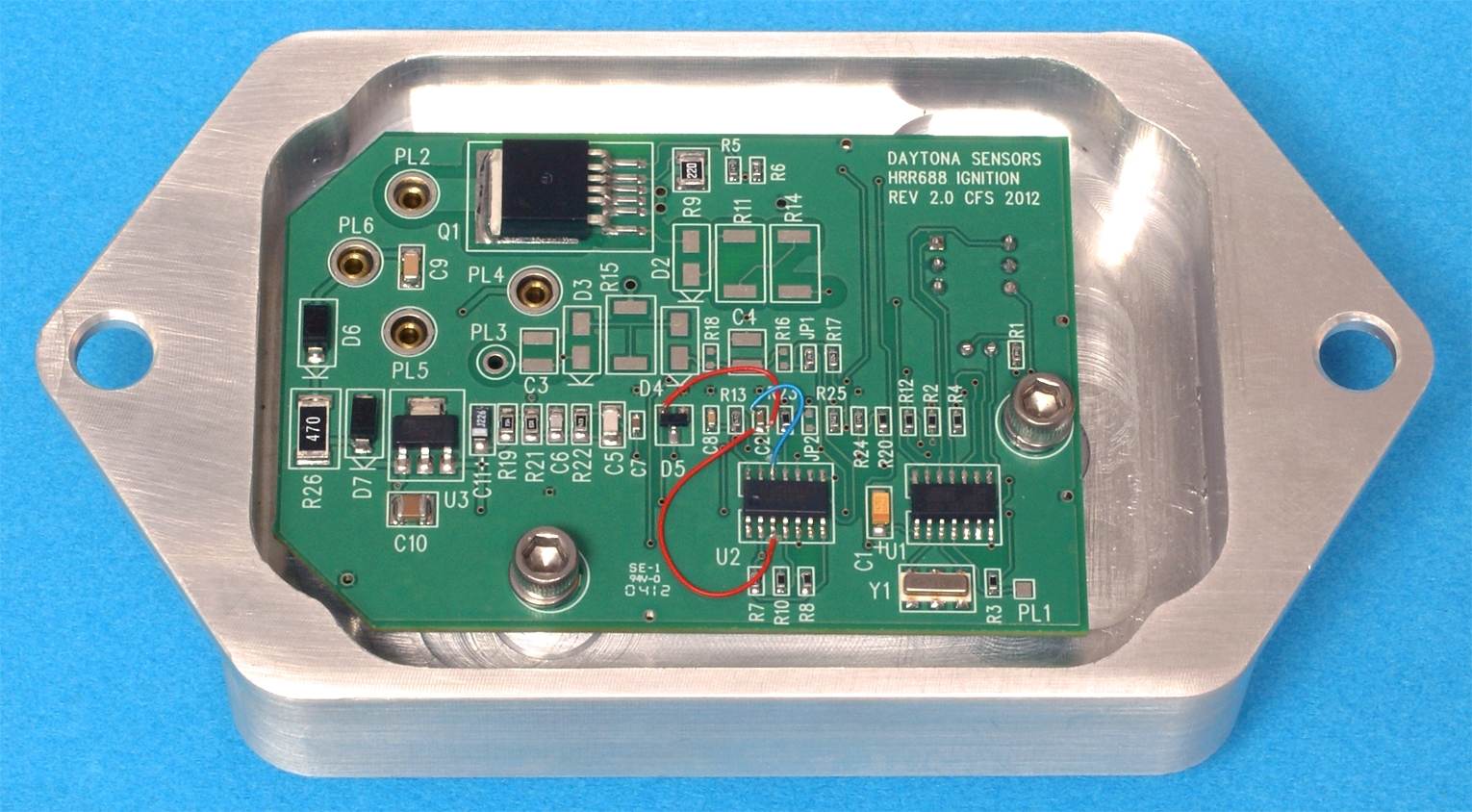

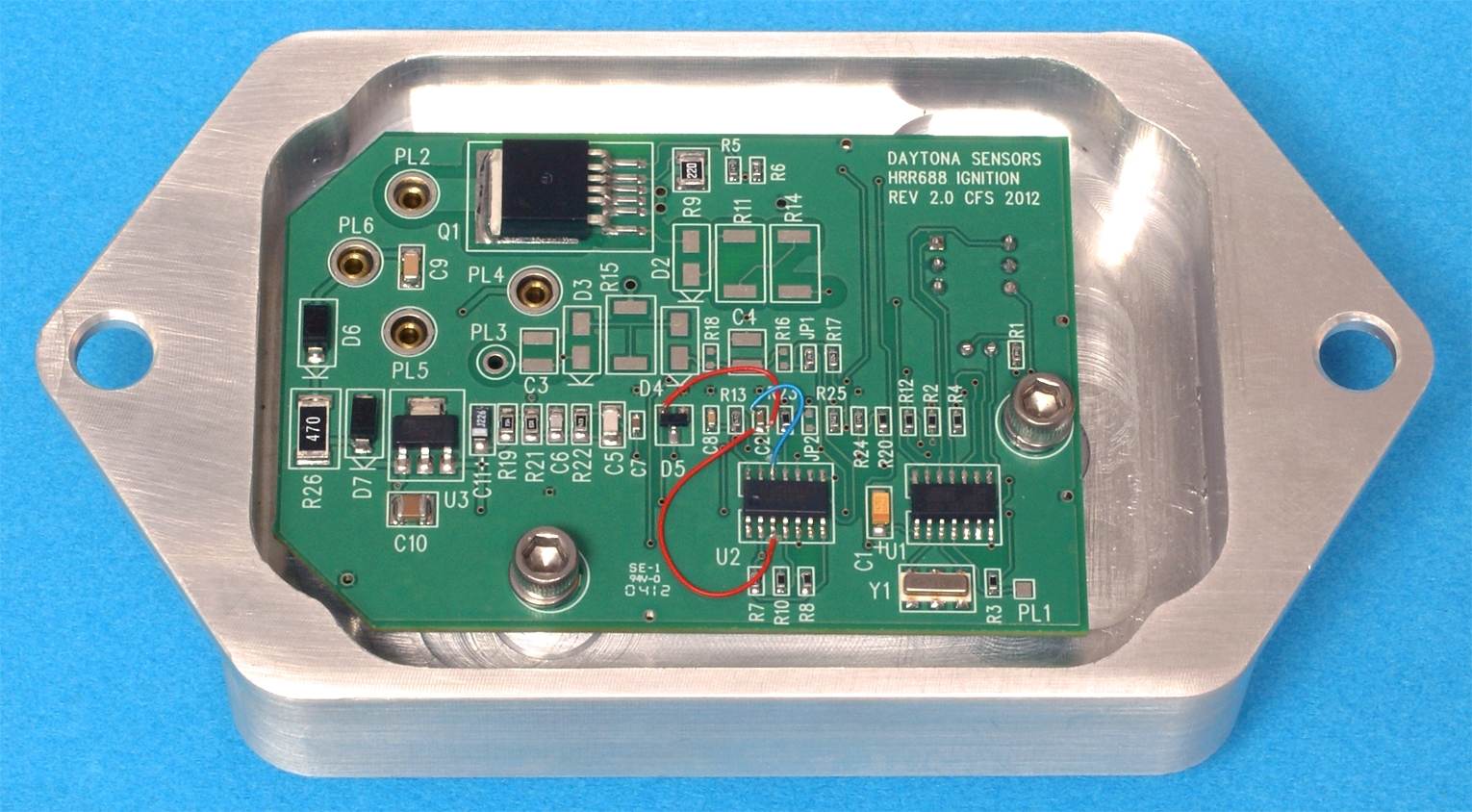

Probably won't do much either way. I don't care for this:

Note the jumper wires and lack of "potting". Potting is that resin type stuff they fill electronic enclosures with to combat vibration and shock failures. The wires look like they would fall off just from shipping.

At $200, I don't see any real "upgrade". There's a claim of increased voltage when starting and some clever "onboard" diagnostics. Losing the ballast resistor isn't a bad thing, but I don't see as that's all that big a deal.

A MSD would be a better upgrade, but like everything else, it's not something a basically stock (or even slightly modded) Mopar would need over the Mopar electronic ignition. IMHO, there's no bang for the buck here....

But.. IMHO, a good (and cheap) upgrade is to go to a GM HEI ignition module with an e-core type coil. There's longer duration spark and when you open up the spark gap, you'll have a higher secondary voltage too. You lose the ballast resistor too. But... People scream "No GM parts!" as they slide behind the steering wheel mounted to the GM sourced steering column... But I digress...

Note the jumper wires and lack of "potting". Potting is that resin type stuff they fill electronic enclosures with to combat vibration and shock failures. The wires look like they would fall off just from shipping.

At $200, I don't see any real "upgrade". There's a claim of increased voltage when starting and some clever "onboard" diagnostics. Losing the ballast resistor isn't a bad thing, but I don't see as that's all that big a deal.

A MSD would be a better upgrade, but like everything else, it's not something a basically stock (or even slightly modded) Mopar would need over the Mopar electronic ignition. IMHO, there's no bang for the buck here....

But.. IMHO, a good (and cheap) upgrade is to go to a GM HEI ignition module with an e-core type coil. There's longer duration spark and when you open up the spark gap, you'll have a higher secondary voltage too. You lose the ballast resistor too. But... People scream "No GM parts!" as they slide behind the steering wheel mounted to the GM sourced steering column... But I digress...

Picture didn't come through.... Here it is.

GregG48203

Active Member

...and Saginaw P.S. pump, and Rochester carburetor...GM sourced steering column

70_NPORT

Well-Known Member

I looked at that also and I don't have too much of a problem with GM ignition, but I DO very much like the idea of loosing the BR....first time seeing this FBO rig; the people on the A body site rave about it...

Some people rave about the Rev-N-Nator too.

Here's the problem.... Folks don't have it right to begin with. They bolt on an upgraded piece and now the car runs OK. If they had gotten the stock stuff right to begin with, they would be fine... but with zero diagnostic skills and a desire to empty their wallet, they buy today's trick.

Here's the problem.... Folks don't have it right to begin with. They bolt on an upgraded piece and now the car runs OK. If they had gotten the stock stuff right to begin with, they would be fine... but with zero diagnostic skills and a desire to empty their wallet, they buy today's trick.

commando1

Old Man with a Hat

Some people rave about the Rev-N-Nator too.

Here's the problem.... Folks don't have it right to begin with. They bolt on an upgraded piece and now the car runs OK. If they had gotten the stock stuff right to begin with, they would be fine... but with zero diagnostic skills and a desire to empty their wallet, they buy today's trick.

65Fury440

Senior Member

Very good write up John.

The thing I didn't like about the distributor were complaints the curve was fudged up, directly opposite of what the intent was of moving to a R2R distributor.

I have no complaints with the Mopar performance ignition on my 440, just about the time it gets to the happy spot idling will be at the spark knock threshold, so that's fine.

Any one using the MSD R2R?

MSD Ignition 8387 | Buy MSD Billet & Pro-Billet Distributors at JEGS

The thing I didn't like about the distributor were complaints the curve was fudged up, directly opposite of what the intent was of moving to a R2R distributor.

I have no complaints with the Mopar performance ignition on my 440, just about the time it gets to the happy spot idling will be at the spark knock threshold, so that's fine.

Any one using the MSD R2R?

MSD Ignition 8387 | Buy MSD Billet & Pro-Billet Distributors at JEGS

I have 2 OF the FBO units in use and a third going in my T&C. I purchased his distributor as well I liked the fact he custom curved it to my application. I have about 10K miles total on both vehicles and no complaints.

BTW they arrive potted the photos on the website are so you can see whats inside ( nothing to hide). There were multiple reasons I chose to purchase the FBO product one of which was the adjustable rev limiter. One of the cars was for my son a 17 year old driver and I never mentioned that the adjustable rev's to him . I was also able to use an Orange box cover with a little modification over this unit as a cover to keep a stock look.

. I was also able to use an Orange box cover with a little modification over this unit as a cover to keep a stock look.

BTW they arrive potted the photos on the website are so you can see whats inside ( nothing to hide). There were multiple reasons I chose to purchase the FBO product one of which was the adjustable rev limiter. One of the cars was for my son a 17 year old driver and I never mentioned that the adjustable rev's to him

Last edited:

70_NPORT

Well-Known Member

Either way I'm gonna go through the ignition system (under hood). I know the alternator is shot...barely makes 12.25v at idle (IIRC it should be at least 13v?).....and there is a misfire at idle..but seems to smooth out at higher RPMs. Yesterday the motor cut off completely while sitting at idle and was a total ***** to start again, had to let it sit for a few minutes to get it to turn over. I don't trust the orange ECUs either, got the third third box on the firewall now..and the same behavior was occurring right before the second ECU took a dump...so I haven't checked everything with a multimeter yet (except batt and alt) but I have to wonder if that is the culprit..again.

That's good to know. I don't understand why they would show it like that without showing that the finished product is potted.BTW they arrive potted the photos on the website are so you can see whats inside ( nothing to hide).

Have you noticed any actual improvements?

That's a little low at idle, but check it at about 1000 RPM.Either way I'm gonna go through the ignition system (under hood). I know the alternator is shot...barely makes 12.25v at idle (IIRC it should be at least 13v?).....and there is a misfire at idle..but seems to smooth out at higher RPMs. Yesterday the motor cut off completely while sitting at idle and was a total ***** to start again, had to let it sit for a few minutes to get it to turn over. I don't trust the orange ECUs either, got the third third box on the firewall now..and the same behavior was occurring right before the second ECU took a dump...so I haven't checked everything with a multimeter yet (except batt and alt) but I have to wonder if that is the culprit..again.

You seem to have more problems with ignition and wiring than is normal. A lot more... Something else is wrong.

Here is a post by the owner on Dodgechargerforum from 2012.

Let’s clarify all these unsubstantiated statements about our new HRR688 Ignition Box and lets go with the actual facts and not this bogus rhetoric.

This is NOT a GM Module in any way shape or form.

The HRR688 was co-designed by us and probably the most brilliant Automotive Electronics Engineer on this planet. It’s 100% assembled in America to extremely rigid electronics manufacturing specifications by one of the best Automotive Electronics Manufacturers in this nation, Daytona-Sensors in Daytona Beach Florida. The billet housings are made by PRP (Philadelphia Racing Products) The boards were prototyped and are currently built by a company in California (some electronic components are imported). The pins are also made in California, the labels are printed in Portland Or. with final assembly done right here in our shop.

The Algorithm REV Limiter is the same Digital Technology that you'll find in the high price units from Crane and Daytona-Sensors CD-1 and CD-Pro and “some” other capacitor ignitions. It starts at 5200 and adjusts at 200 RPM per click to 7000 RPM. 7,000 RPM is the limit for inductive ignition and if you need more than 7K you should consider the CD-1 or CD-Pro capacitor style ignition systems. You can not "Drive Thru" this REV Limiter. It is a true fully “Digital” ignition and accurate to .01%. It will NOT drop cylinders, it will NOT retard the timing and it will NOT drop output.

The LED light on the face is a self diagnostic system, when the power is turned on the box does a systems check and illuminates to show correct operation. When the engine is cranked it will flash as each cylinder is triggered, once it fires the motor it’s still flashing but too fast for you to see with the naked eye. Film it and watch in slo-mo and you’ll see it. If the LED lights but doesn’t flash when cranking then the pickup in the distributor is not sending a signal to the box.

The HRR688 uses voltage amplifier circuitry that when triggered takes that very tiny Voltage signal or trigger signal going to the electronic box up to battery voltage (similar to a relay). This high voltage is then controlled by a voltage regulator on the circuit board which reduces it to 5.5V to run the computer style circuit board to fire the ignition with extreme accuracy.

We challenge anyone with a Slant 6 or V8 to compare this product to any inductive ignition box available anywhere on this planet , in any test this ignition platform will exceed anything you can compare it to. Show me the certified Engineering data!

Is it 100% fail proof? Of course not as with any mechanical or digital component you must create a Bathtub curve for expected failure rates. This is done by hours of painstaking and expensive testing and calculated by the sum of all components. All Products whether it’s a Road Hazard on a tire or an ignition box have a calculated failure rate based on this formula and every part has a built in cost to cover this tub. Some ignition companies have a tub that looks more like a bucket and the costs to cover excessive failures are buried in the MSRP. Send it back for warranty and they send you another, you’ve already paid for 2 anyhow.

This “Bathtub Curve” is widely used in reliability engineering ours is almost flat or as we refer to it “not much water in our tub” you can read more about the Bathtub Curve and how they calculate it here:Bathtub curve - Wikipedia, the free encyclopedia

The problem with some ignition boxes or modules is not always the box or module itself but the signal received from the weak and borderline spec pick-up coils produced offshore and used by all current manufacturers of replacement and OE distributors. The pickup coils are simply a small generator that produces a voltage signal as the reluctor passes over the magnet; this very low voltage signal triggers the box to fire the plug. As with all generators the slower they spin the lower the output and the harder it is for the box to read the signal. At low cranking RPM the generator on these cheap and minimum spec generators can’t fire what some are referring to as a GM module. GM pickup coils have a much higher voltage output by design than a Mopar pickup coil. Stock GM modules under full load will run to 4800-5200 RPM and then fall off, aftermarket modules will run much higher and are exponentially more money. Imported modules may start to fail as low 3200.

Think about this….. In the muscle car days these HP engines were covered under warranty, do you think that Mopar, GM or even Ford really wanted you spinning these engines to 6500-6800-7000 RPM? Change the module on these cars and your warranty was void. They were designed to run only to the manufacturers safe operating RPM. Why would Mopar put an ignition system in a 50,000 mile power train warranty program that would spin the motor to 7200-7500? They would have been replacing engines every Monday morning. New cars all have rev limiters my old V10 Dodge 1 ton would go to 4800 and right into stutter.

All parts have a minimum and maximum operating range set by the engineers who design these parts, if you’re always working to the minimum you will likely get mediocre results. The issue with the HR688 wasn’t the aftermarket 4 pin module but it’s inability to read the weak voltage generated by the low quality pickup coils at low crank RPM. If you build the electronics to read the very low signal then you can get RFI signals that will falsely trigger the ignition. So it’s a fine line….too sensitive and you get cross firing or low sensitivity and the low output imported generators don’t put out enough to trigger it at low RPM. It really comes down to the imported offshore low quality parts that this country is plagued with, minimum standards, poor quality control and corporate greed to make everything cheaper whether it works or not.

Between Daytona-Sensors and ourselves we have the most sophisticated ignition related electronic testing equipment available, some pieces we have built ourselves to test max extreme conditions. Our distributor machines (4) have all been re-geared to run over 8,500 RPM which is common in S/E racing, those guys will shift at 8200-8800 and some even higher, how can you isolate a high RPM issue if you can’t duplicate it on the test equipment?

We challenge anyone to give us factual test data results that disprove any of our performance claims on this ignition box. If you can't back it up perhaps you shouldn't say it, our Engineer or myself will be happy to answer any technical questions you may have and provide test data that we feel is non-propriotory.

All operational specs on the HRR688 box are on our webpage at www.4secondsflat.com/Ignition.html

Let’s clarify all these unsubstantiated statements about our new HRR688 Ignition Box and lets go with the actual facts and not this bogus rhetoric.

This is NOT a GM Module in any way shape or form.

The HRR688 was co-designed by us and probably the most brilliant Automotive Electronics Engineer on this planet. It’s 100% assembled in America to extremely rigid electronics manufacturing specifications by one of the best Automotive Electronics Manufacturers in this nation, Daytona-Sensors in Daytona Beach Florida. The billet housings are made by PRP (Philadelphia Racing Products) The boards were prototyped and are currently built by a company in California (some electronic components are imported). The pins are also made in California, the labels are printed in Portland Or. with final assembly done right here in our shop.

The Algorithm REV Limiter is the same Digital Technology that you'll find in the high price units from Crane and Daytona-Sensors CD-1 and CD-Pro and “some” other capacitor ignitions. It starts at 5200 and adjusts at 200 RPM per click to 7000 RPM. 7,000 RPM is the limit for inductive ignition and if you need more than 7K you should consider the CD-1 or CD-Pro capacitor style ignition systems. You can not "Drive Thru" this REV Limiter. It is a true fully “Digital” ignition and accurate to .01%. It will NOT drop cylinders, it will NOT retard the timing and it will NOT drop output.

The LED light on the face is a self diagnostic system, when the power is turned on the box does a systems check and illuminates to show correct operation. When the engine is cranked it will flash as each cylinder is triggered, once it fires the motor it’s still flashing but too fast for you to see with the naked eye. Film it and watch in slo-mo and you’ll see it. If the LED lights but doesn’t flash when cranking then the pickup in the distributor is not sending a signal to the box.

The HRR688 uses voltage amplifier circuitry that when triggered takes that very tiny Voltage signal or trigger signal going to the electronic box up to battery voltage (similar to a relay). This high voltage is then controlled by a voltage regulator on the circuit board which reduces it to 5.5V to run the computer style circuit board to fire the ignition with extreme accuracy.

We challenge anyone with a Slant 6 or V8 to compare this product to any inductive ignition box available anywhere on this planet , in any test this ignition platform will exceed anything you can compare it to. Show me the certified Engineering data!

Is it 100% fail proof? Of course not as with any mechanical or digital component you must create a Bathtub curve for expected failure rates. This is done by hours of painstaking and expensive testing and calculated by the sum of all components. All Products whether it’s a Road Hazard on a tire or an ignition box have a calculated failure rate based on this formula and every part has a built in cost to cover this tub. Some ignition companies have a tub that looks more like a bucket and the costs to cover excessive failures are buried in the MSRP. Send it back for warranty and they send you another, you’ve already paid for 2 anyhow.

This “Bathtub Curve” is widely used in reliability engineering ours is almost flat or as we refer to it “not much water in our tub” you can read more about the Bathtub Curve and how they calculate it here:Bathtub curve - Wikipedia, the free encyclopedia

The problem with some ignition boxes or modules is not always the box or module itself but the signal received from the weak and borderline spec pick-up coils produced offshore and used by all current manufacturers of replacement and OE distributors. The pickup coils are simply a small generator that produces a voltage signal as the reluctor passes over the magnet; this very low voltage signal triggers the box to fire the plug. As with all generators the slower they spin the lower the output and the harder it is for the box to read the signal. At low cranking RPM the generator on these cheap and minimum spec generators can’t fire what some are referring to as a GM module. GM pickup coils have a much higher voltage output by design than a Mopar pickup coil. Stock GM modules under full load will run to 4800-5200 RPM and then fall off, aftermarket modules will run much higher and are exponentially more money. Imported modules may start to fail as low 3200.

Think about this….. In the muscle car days these HP engines were covered under warranty, do you think that Mopar, GM or even Ford really wanted you spinning these engines to 6500-6800-7000 RPM? Change the module on these cars and your warranty was void. They were designed to run only to the manufacturers safe operating RPM. Why would Mopar put an ignition system in a 50,000 mile power train warranty program that would spin the motor to 7200-7500? They would have been replacing engines every Monday morning. New cars all have rev limiters my old V10 Dodge 1 ton would go to 4800 and right into stutter.

All parts have a minimum and maximum operating range set by the engineers who design these parts, if you’re always working to the minimum you will likely get mediocre results. The issue with the HR688 wasn’t the aftermarket 4 pin module but it’s inability to read the weak voltage generated by the low quality pickup coils at low crank RPM. If you build the electronics to read the very low signal then you can get RFI signals that will falsely trigger the ignition. So it’s a fine line….too sensitive and you get cross firing or low sensitivity and the low output imported generators don’t put out enough to trigger it at low RPM. It really comes down to the imported offshore low quality parts that this country is plagued with, minimum standards, poor quality control and corporate greed to make everything cheaper whether it works or not.

Between Daytona-Sensors and ourselves we have the most sophisticated ignition related electronic testing equipment available, some pieces we have built ourselves to test max extreme conditions. Our distributor machines (4) have all been re-geared to run over 8,500 RPM which is common in S/E racing, those guys will shift at 8200-8800 and some even higher, how can you isolate a high RPM issue if you can’t duplicate it on the test equipment?

We challenge anyone to give us factual test data results that disprove any of our performance claims on this ignition box. If you can't back it up perhaps you shouldn't say it, our Engineer or myself will be happy to answer any technical questions you may have and provide test data that we feel is non-propriotory.

All operational specs on the HRR688 box are on our webpage at www.4secondsflat.com/Ignition.html

70_NPORT

Well-Known Member

Thats possible. It is strange however when I parked it to retro fit the disc brakes job it was running smoothly. Only sat for two months.That's a little low at idle, but check it at about 1000 RPM.

You seem to have more problems with ignition and wiring than is normal. A lot more... Something else is wrong.

70_NPORT

Well-Known Member

How much "play" is allowable in the dist shaft..if any?

What type of "play".

You can grab the rotor and give it a twist and that is just the mechanical advance. There is a slight amount of up and down and that can be ajusted with shims. Then there's side play and this would affect the amount of gap between the reluctor and pickup. That should be minimal, but there will be some.

You can grab the rotor and give it a twist and that is just the mechanical advance. There is a slight amount of up and down and that can be ajusted with shims. Then there's side play and this would affect the amount of gap between the reluctor and pickup. That should be minimal, but there will be some.

But... If the inside of the cap looks as crappy as that rotor, that can cause some crossfire etc.

70_NPORT

Well-Known Member

I drive my car. A lot.

However the inside of the cap isn't bad; a little bit of carbon build up but not enough to justify trashing the cap. I have noticed however the rotor and reluctor "rotate" either clockwise or counterclockwise a small amount. This shouldn't be able to move at all when the engine isn't running..or so I thought.

However the inside of the cap isn't bad; a little bit of carbon build up but not enough to justify trashing the cap. I have noticed however the rotor and reluctor "rotate" either clockwise or counterclockwise a small amount. This shouldn't be able to move at all when the engine isn't running..or so I thought.

The rotational movement is part of the mechanical advance. As the RPM increases, the weights move outwards and turn the top portion of the distributor shaft/rotor to advance the timing. So what you are feeling is 100% normal.I drive my car. A lot.

However the inside of the cap isn't bad; a little bit of carbon build up but not enough to justify trashing the cap. I have noticed however the rotor and reluctor "rotate" either clockwise or counterclockwise a small amount. This shouldn't be able to move at all when the engine isn't running..or so I thought.

If you have carbon in the cap, replace it. The carbon can cause all sorts of issues with misfires.

From just one source... The Path Of Least Resistance

Google "distributor cap carbon tracking" for more info.

The DISTRIBUTOR CAP is often subject to cracking, carbon tracking, oxidation and ionization, all causes of misfire and crossfire. One of the most important spots to check is the carbon contact, located in the inside center of the cap, which wears over time, requiring that the cap be replaced. Caps that include blue/green corrosion on the terminals, or a black, powdery substance, referred to as carbon tracking, should be cleaned or discarded. Ionization is a condition where the air inside the cap become electronically charged, creating spark scatter or crossfire.

Google "distributor cap carbon tracking" for more info.

Similar threads

- Replies

- 3

- Views

- 703

- Replies

- 12

- Views

- 2K