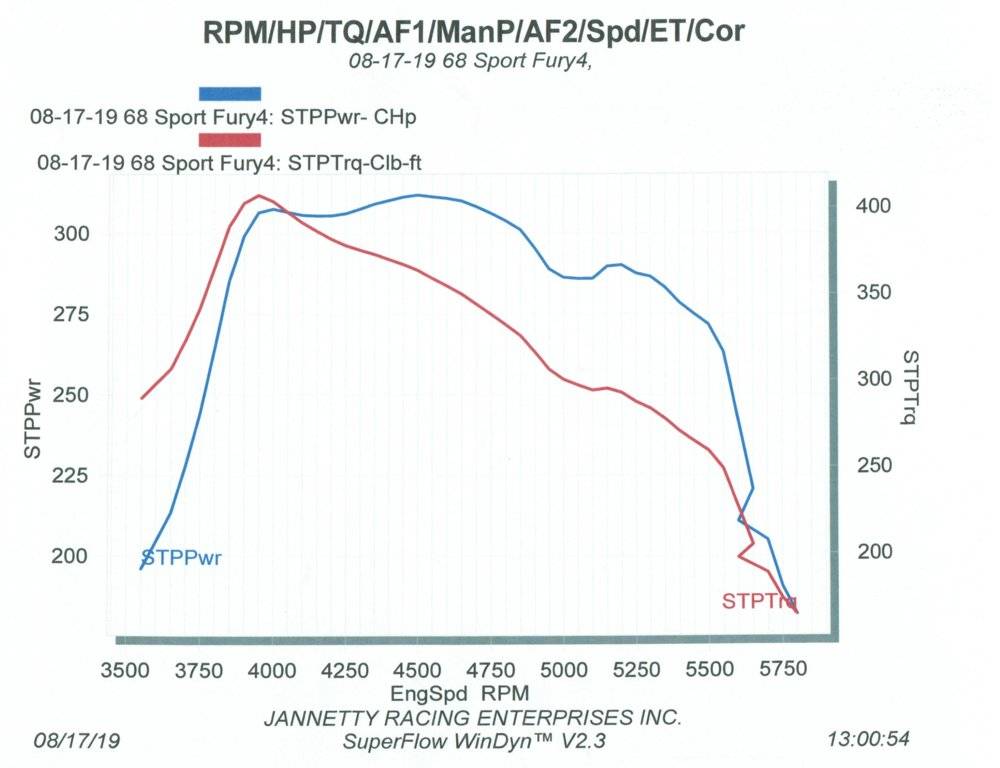

312 HP at the rear wheels at 4500 RPM and 408 torque at 3950 RPM.

Since the torque converter has a higher than stock stall speed it is not possible to accurately estimate the engine figures.

The engine is a pump gas 10:1 compression ratio stock appearing engine with factory intake and exhaust manifolds as the car is built to race in the stock appearing racing classes.

Since the torque converter has a higher than stock stall speed it is not possible to accurately estimate the engine figures.

The engine is a pump gas 10:1 compression ratio stock appearing engine with factory intake and exhaust manifolds as the car is built to race in the stock appearing racing classes.