My plan is to replace the front subframe in my '67 Monaco with this one:

I'm showing here the underside rear passenger side. I would of course clean this frame up and paint it, but I want to go further.

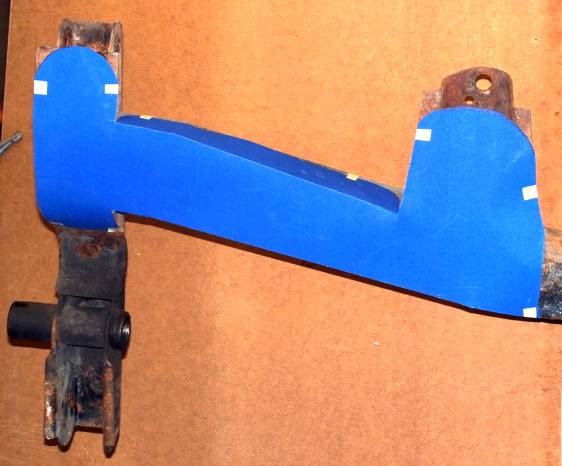

I want to form this out of 3/16 plate steel:

And weld it to the frame:

Here's a shot of the driver-side rear:

The yellow circle is where I think a lift-support is usually placed. On this side, for what-ever reason, that area is some-what pressed in (concave) compared to the same area on the passenger side. Correct me if I'm wrong, but if there was an area on these frames that could use some extra beef, it would be that area.

Aside from a rusty / greasy look, this frame has no rot. If my current frame were in this same exact condition and appearance I wouldn't be touching it.

But since I always want to "make it better", I have this idea that the above-described reinforcement scheme will do what I want.

Or is this not a good way to go?

I'm showing here the underside rear passenger side. I would of course clean this frame up and paint it, but I want to go further.

I want to form this out of 3/16 plate steel:

And weld it to the frame:

Here's a shot of the driver-side rear:

The yellow circle is where I think a lift-support is usually placed. On this side, for what-ever reason, that area is some-what pressed in (concave) compared to the same area on the passenger side. Correct me if I'm wrong, but if there was an area on these frames that could use some extra beef, it would be that area.

Aside from a rusty / greasy look, this frame has no rot. If my current frame were in this same exact condition and appearance I wouldn't be touching it.

But since I always want to "make it better", I have this idea that the above-described reinforcement scheme will do what I want.

Or is this not a good way to go?