I received my service manual for my 16-000, so I decided to tear down my 15-000 exhaust gas analyzer. I couldn’t stand not knowing what all was in there.

Actually it doesn’t loo that complicated. Although I have no Idea how the nuclear reactor tubes with the glass ends and the mirrors work yet.

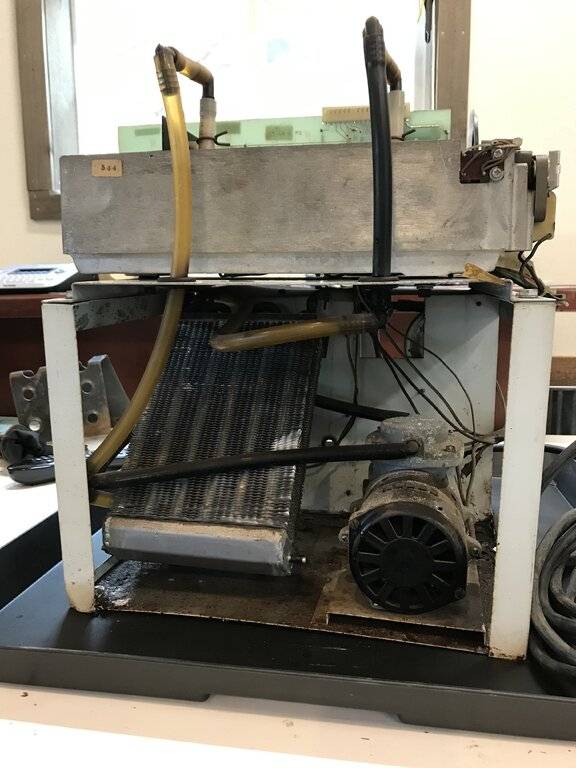

It consists of the exhaust sniffer inlet running through an air pump through a filter, T’s off with one end going to a diafram sensor (Or it could be a pressure regulator that controls the air pump). The other T outlet goes into a cooler or condenser of sorts and flows through the nuclear reactor ( glass tubes with mirrors) and then flows out of the machine. It is quite interesting, but not sure how every thing works yet. Will take apart, blast the cabinet and do some body work while I am trying figure it all out.

Actually it doesn’t loo that complicated. Although I have no Idea how the nuclear reactor tubes with the glass ends and the mirrors work yet.

It consists of the exhaust sniffer inlet running through an air pump through a filter, T’s off with one end going to a diafram sensor (Or it could be a pressure regulator that controls the air pump). The other T outlet goes into a cooler or condenser of sorts and flows through the nuclear reactor ( glass tubes with mirrors) and then flows out of the machine. It is quite interesting, but not sure how every thing works yet. Will take apart, blast the cabinet and do some body work while I am trying figure it all out.