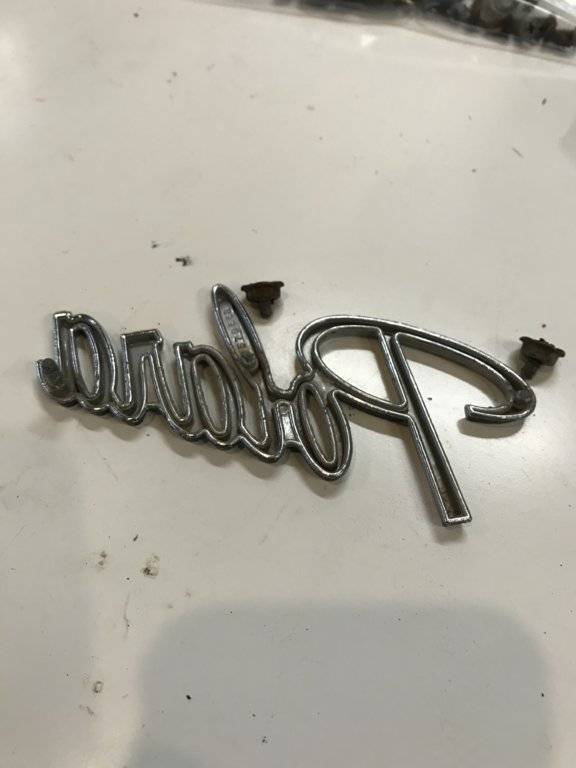

My Polara emblems are in pretty nice shape with no pitting and should clean up nicely. But a couple of the studs twisted off when removing the thread cutting nuts. Has anyone had success with JB weld epoxy? Or ordering the special welding rod for pot metal and re- attaching them?

Thank you

Thank you