Let’s finish up this exhausting whirlwind of posts with what else, the exhaust!

Once again, options abound if you want your 440 to sound like the monster most people think it is. Three inch pipes, dual exhaust, HP logs, headers and what not. All I wanted was a stock single 2 1/4 inch pipe with the correct muffler and tail pipe. Many years earlier I had sourced an NOS Y pipe.

View attachment 416974

Just glad I could help. Looking good

Next I found an eBay seller with a bunch of NOS tail pipes, so I snapped this one up, complete with resonator and correct turn-down. It had been for sale for years, I literally saw some one post the link here in 2018, and of course it was still for sale. I was aghast when it showed up wrapped in plastic, but actually it came out perfect and in record time.

View attachment 416963

The muffler was another mystery, I ended up sourcing one based on size and shape. However, the hardest part was this mid pipe circled in red below.

View attachment 416964

In my search for a junk pipe that I could bring to the muffler shop as a bending guide (no, they had never heard of “bend” cards, nor how to use them), a member here came through with a solid usable piece! Thanks again @JDX. The bigger problem was shipping, so I suggested the classic plastic wrap method and it was here in a jiffy.

View attachment 416969

Now just blast the hangars and put this baby back together. Is that an old tire? It came from an unmolested car, but who knows, still, that rivet looks original.

View attachment 416965 View attachment 416966 View attachment 416967 View attachment 416970

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Resurrection of my 1970 Chrysler 300 Convertible

- Thread starter Samplingman

- Start date

Samplingman

Old Man with a Hat

Starting up the build thread for my 11th season for no other reason than to use my 5000th post! No big deal, I’ve been an old man with a hat for many years already, so on with the show!

First off, the air cleaner needed some love, and with the help of a recently found Mopar “do not wash” sticker and some thin weather strip from Home Depot, it looks good as new. The sticker is from Year One, purchased in 1982 but never used for my ‘70 Challenger restoration. I think it’s the same, but I don’t care, it’s a tribute to a car long gone.

First off, the air cleaner needed some love, and with the help of a recently found Mopar “do not wash” sticker and some thin weather strip from Home Depot, it looks good as new. The sticker is from Year One, purchased in 1982 but never used for my ‘70 Challenger restoration. I think it’s the same, but I don’t care, it’s a tribute to a car long gone.

Samplingman

Old Man with a Hat

Early on I noticed a nasty chip out of one of the tangs of the drive shaft yoke. I thought no big deal, I’ll find another. For some reason finding the coarse spline in the correct size was giving me fits, so I decided to weld it up and torque the bolts down with the new U joint to see if it would hold. The shaft is a piece of aluminum rod to prevent the threads from filling up with weld. Not too bad and it is holding up well enough for yard running, if not for cruising.

Samplingman

Old Man with a Hat

Speaking of driveshaft, that got the refresh treatment as well. A good phosphoric acid bath an a few coats of aluminum paint and it’s hood to go. Ok we are not talking concourse resto or even number 1 show status, just doin’ it like I did in High School, well maybe a bit better.

Samplingman

Old Man with a Hat

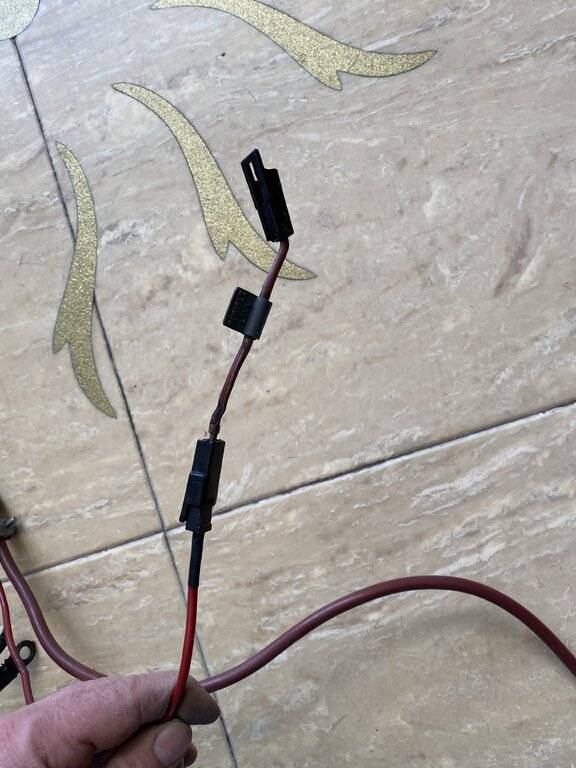

Here is my version of a “day two” positive cable with correct fusible link. Some day these vendors will create a correct cable, but my build is not waiting. Really, just how difficult is it to recreate?

What we used to do to strengthen that assembly for the drag cars was to drill those holes out to a tight clearance hole for the next size bolt (I think 3/8 or was it 5/16? ) and drill completely through and add a nut with lock washer to the back. Use a Grade 8 Allen cap screw.Early on I noticed a nasty chip out of one of the tangs of the drive shaft yoke. I thought no big deal, I’ll find another. For some reason finding the coarse spline in the correct size was giving me fits, so I decided to weld it up and torque the bolts down with the new U joint to see if it would hold. The shaft is a piece of aluminum rod to prevent the threads from filling up with weld. Not too bad and it is holding up well enough for yard running, if not for cruising.

View attachment 454559 View attachment 454560 View attachment 454562 View attachment 454563 View attachment 454564 View attachment 454565 View attachment 454566 View attachment 454567 View attachment 454568

We used to break the stock bolts, but never broke one after that mod. If your weld is good, adding this bolt should work real well to save that yoke.

That air cleaner really looks great. Make sure you slam the hood down over that long carb stud.First off, the air cleaner needed some love, and with the help of a recently found Mopar “do not wash” sticker and some thin weather strip from Home Depot, it looks good as new. The sticker is from Year One, purchased in 1982 but never used for my ‘70 Challenger restoration. I think it’s the same, but I don’t care, it’s a tribute to a car long gone.

As for that sticker, I got one with my repro pie plate. But....my recently purcha$$$ed (at the time), used air cleaner already had a sticker with some sweet little "patina" marks on it....no way I was going to replace it with "new"!

Make sure you slam the hood down over that long carb stud.

Quick story... A friend worked in a small gas station/repair shop. He had a pretty good reputation although one of the owners had just the opposite but was known to be really good with getting there first with the tow truck. He was working on this nice C3 Corvette, installing a new manifold and Holley carb. He had just put the air cleaner on with a long stud and was going back to his tool box to get something to mark where to cut the stud off. His boss (aforementioned owner) came along and said "Hey! All done!" and slammed the hood. The stud popped a nice little hole in the hood.

My friend just leaned over, put the wing nut on the stud poking through and said "There ya go, you can deal with it now" and walked away.

Ask QQE. They're the "experts".......Really, just how difficult is it to recreate?

You might want to use this cable head, sold by MegaParts (and others). It's the bizzness, with Allen setscrews underneath for a really nice look to your very nice cable. However, they had a batch where the threading for the setscrews didn't go all the way through and you couldn't tighten down on the cables at all. Tapping new threads in lead isn't an easy thing to do (correctly), so I drilled out the holes and and installed threaded inserts. Doing that, I could REALLY get a good crush on those cables!

EDIT: See post 472 regarding the battery heads from Megaparts.

And yes, I painted that ugly green Ground Disconnect knob black.

Last edited:

I'd do one of these... Solder on, and they often even have a solder "pellet" to make things easier.

I really, really don't like the clamp on battery terminals. They are temporary solutions.

I really, really don't like the clamp on battery terminals. They are temporary solutions.

Samplingman

Old Man with a Hat

Quick story... A friend worked in a small gas station/repair shop. He had a pretty good reputation although one of the owners had just the opposite but was known to be really good with getting there first with the tow truck. He was working on this nice C3 Corvette, installing a new manifold and Holley carb. He had just put the air cleaner on with a long stud and was going back to his tool box to get something to mark where to cut the stud off. His boss (aforementioned owner) came along and said "Hey! All done!" and slammed the hood. The stud popped a nice little hole in the hood.

My friend just leaned over, put the wing nut on the stud poking through and said "There ya go, you can deal with it now" and walked away.

Believe it or not the stud fits as is, the carb came out of the parts car, but I am cutting it down, unscrewing that thing took forever.

I'd do one of these... Solder on, and they often even have a solder "pellet" to make things easier.

I really, really don't like the clamp on battery terminals. They are temporary solutions.

Temporary AND butt-ugly. The solder-on is best if you can find one that looks right, and the one you show looks pretty good. When I had my setscrew thread issue, I thought about doing a solder job. But I quickly thought better of it because I knew the melting point of the soft lead head and solder were "similar", and I didn't want to make a blob out of my positive head.

Incidentally, I just had a look at Megaparts. It appears they no longer carry 102-PR Positive Battery Cable Replaceable Head [$35], probably because they had to send me a replacement to the first one and both had thread problems. I had Jamie on the phone a year ago, and he discovered that all the heads he had in stock wouldn't screw down to the cable. Oh well.

Samplingman

Old Man with a Hat

Speaking of batteries, I do want one of those faux Mopar covers.

For the start up, I thought I’d put the battery tray in, looked easy enough, two bolts and a bracket to the radiator support with a fourth bolt into the inner fender well.

Not so fast, the convertible setup is different than the hard top. I had recently sourced the bracket, but went crazy trying to find the mounting on the support.

Here it is on the hard top:

I know this support is original to the car and I was not going to drill a random mounting hole.

As it turns out, a different bracket for non-TQ stub mounts to the frame, not the support.

Just crazy!

For the start up, I thought I’d put the battery tray in, looked easy enough, two bolts and a bracket to the radiator support with a fourth bolt into the inner fender well.

Not so fast, the convertible setup is different than the hard top. I had recently sourced the bracket, but went crazy trying to find the mounting on the support.

Here it is on the hard top:

I know this support is original to the car and I was not going to drill a random mounting hole.

As it turns out, a different bracket for non-TQ stub mounts to the frame, not the support.

Just crazy!

Samplingman

Old Man with a Hat

Exactly why I went with the “day two” look. I tried and indeed ended up with a blob.When I had my setscrew thread issue, I thought about doing a solder job. But I quickly thought better of it because I knew the melting point of the soft lead head and solder were "similar", and I didn't want to make a blob out of my positive head.

Speaking of batteries, I do want one of those faux Mopar covers.

No you don't. You want one of these: Mopar Battery S27M red (1966-74) Push in Caps kit | eBay

I have one. Love it. Notice the "caps" are stuck onto the square vents. Nobody notices, but I have heard "Wow, that guy sprung for one of those expensive repro batteries!"

This battery started out as an OReilly Super Start Group 27. When you pull the ugly stickers off of it you're left with a plain black box of a battery, just WAITING for that sticker kit.

Last edited:

Exactly why I went with the “day two” look. I tried and indeed ended up with a blob.

BLOB!! Hilarious! And you're the guy who is skillfully welding-up ujoint yokes!

You might try calling Megaparts [608-452-2045] and ask Jamie if he has any of those defective heads still around. Now that you know ahead of time that they need either VERY careful tapping or inserts, you can easily have a nice new, correct head. Instead of ugly.

Samplingman

Old Man with a Hat

I also resolved an earlier issue with the wrong radiator mounting. My expensively re-cord radiator was apparently from a B body and would not line up with my new fan shroud or the original support.

Fortunately, I found some C body brackets on eBay, cut and welded, good as new.

Once again, why make a bajillion different variations of stuff?? No wonder they went out of business.

Fortunately, I found some C body brackets on eBay, cut and welded, good as new.

Once again, why make a bajillion different variations of stuff?? No wonder they went out of business.

Samplingman

Old Man with a Hat

BLOB!! Hilarious! And you're the guy who is skillfully welding-up ujoint yokes!

You might try calling Megaparts [608-452-2045] and ask Jamie if he has any of those defective heads still around. Now that you know ahead of time that they need either VERY careful tapping or inserts, you can easily have a nice new, correct head. Instead of ugly.

LOL, I have a general fear of gas torches. Any first year plumbers apprentice will tell you there is a big difference between Soldering and Welding. If you are not careful, one may burn your retinas, but the other can burn your house down!

After the build is done I will then spend the rest of my days getting rid of “the ugly”, until then if it works.....

Samplingman

Old Man with a Hat

And finally, two soon to be classic vids I like to call blowing stuff up, and moving forward under its own power.

On to the metal work!

On to the metal work!

But I quickly thought better of it because I knew the melting point of the soft lead head and solder were "similar"

The battery terminals are a copper alloy and not the lead alloy like the OEM. They still have a silver finish that I assume is the copper being "tinned" with solder.

Similar threads

- Replies

- 4

- Views

- 774