A genuine question! So I'm restoring a '68 New Yorker and I've got my engine and trans newly rebuilt. Stock, the car has a TRW pump... has anyone ever swapped it out for a Federal or a Saginaw style pump? Would it be difficult? Car is an AC car. I really want to update everything and have a nice mechanically sound car; and I figure since the car is in pieces now I might as well take care of things like that at this time! I appreciate any help I get. I only mention a steering pump swap because there just aren't many places to get parts for this pump and I'd rather have something easy that works.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steering Pump Swap?

- Thread starter Isaiah Estrada

- Start date

My two 1966 cars have the same power steering mounting bracket (the much maligned V-style flopper), and one car has a TRW pump and the other a Federal. They can easily swap back and forth. Hose locations are identical.

I don't know which style of mounting bracket your 440 has, so I can't say for certain if it's possible on your car. Pics of your pump and bracket would help.

I don't know which style of mounting bracket your 440 has, so I can't say for certain if it's possible on your car. Pics of your pump and bracket would help.

My two 1966 cars have the same power steering mounting bracket (the much maligned V-style flopper), and one car has a TRW pump and the other a Federal. They can easily swap back and forth. Hose locations are identical.

I don't know which style of mounting bracket your 440 has, so I can't say for certain if it's possible on your car. Pics of your pump and bracket would help.

Mine has the V-style flopper! I don't have pics at the moment but I'll snap some later in the day. Say I did decide to swap the TRW to a Federal. Would it just be a bolt on configuration? Of course I'd get the correct high pressure hose, but would it be able to connect to my steering box? Many thanks!

I believe so. I also would think that the hoses are the same. The only other caveat is the pulley alignment. Even if thd both bolt up to the bracket, both pumps need to have their pulleys in the same place to align with the crank pulley.

Pics will help.

As well, why not just have the pump you've got now rebuilt? You know it fits, and it's likely all that it might need is new seals. Those pumps are pretty bullet proof...

Pics will help.

As well, why not just have the pump you've got now rebuilt? You know it fits, and it's likely all that it might need is new seals. Those pumps are pretty bullet proof...

The saginaw pump is supposed to be superior for road feel because it can be adjusted (using different springs internally) to give less pressure. I don't know if it really has any other benefits other than that.

But, just to reinforce what Ross is saying, the stock pump isn't really bad, most just need a rebuild and need to be adjusted properly.

But, just to reinforce what Ross is saying, the stock pump isn't really bad, most just need a rebuild and need to be adjusted properly.

Seems like the TRW and Federal pumps are completely interchangeable in the same brackets, but a look in the parts book might confirm that.

Personally, I like the ps bracket AND how it works. Genius, to me. Usually, never did hear a power steering belt squawk on a Chrysler with that bracket in a shopping center parking lot, unlike similar Oldsmobiles and Cadillacs. Plus, with the reduced basic tension, the belts lasted a very long time, from my experiences, back then.

Some might suggest going to the smaller-size Saginaw pump, but I'm not completely sure that the Saginaw pump's flow output specs (not pressure, but flow) can match that of the TRW or Federal pump. It is easier to control the boost with the rear fitings drilled orifice size (there were four different sizes), but then one '65 Fury owner (who ran the Gulf station we bought gas from and had a string of '65 Furys, over the years . . . one started to need work, so he'd look for another one just like it) mentioned taking a tire valve stem, cutting it down to size and putting it in the return line as an additional restriction to reduce the pressure. Never did do that to any of our Chryslers, though.

Just some thoughts,

CBODY67

Personally, I like the ps bracket AND how it works. Genius, to me. Usually, never did hear a power steering belt squawk on a Chrysler with that bracket in a shopping center parking lot, unlike similar Oldsmobiles and Cadillacs. Plus, with the reduced basic tension, the belts lasted a very long time, from my experiences, back then.

Some might suggest going to the smaller-size Saginaw pump, but I'm not completely sure that the Saginaw pump's flow output specs (not pressure, but flow) can match that of the TRW or Federal pump. It is easier to control the boost with the rear fitings drilled orifice size (there were four different sizes), but then one '65 Fury owner (who ran the Gulf station we bought gas from and had a string of '65 Furys, over the years . . . one started to need work, so he'd look for another one just like it) mentioned taking a tire valve stem, cutting it down to size and putting it in the return line as an additional restriction to reduce the pressure. Never did do that to any of our Chryslers, though.

Just some thoughts,

CBODY67

70bigblockdodge

Old Man with a Hat

Buy the new brackets, put a Saginaw pump on it and never think about it again. Except for a 1000 point resto there is no need to use one of those small capacity PITA pumps. If they were so good why are they not still making them brand new?

If you pump is working leave it.

If it shits the bed, perfect time for a upgrade

If you pump is working leave it.

If it shits the bed, perfect time for a upgrade

I am glad that @Big_John has posted that video about the V pump bracket. Like him and @CBODY67 , I also like them too, and have never had a problem with them, once I figured out how to preserve their original alignment... the pivot holes get worn, and the bracket twists. Alignment can be improved by adding washers between the pump body and the brackets to realign the assembly.

oldkimmer

Active Member

I think if it ain’t broke don’t fix it. Ur I like the Sag pump also. Kim

RJ Squirrell

Member

Hey Isaiah what did you wind up doing? I have the small .96 TRW pump thats giving me problems, so I am thinking buy the new brackets and a saginaw pump.

John Kirby

Active Member

I went with this:

cvfracing.com

It's a bit expensive but it works very well and looks awesome. There are a couple versions depending on what accessories you have. Don't buy the pump from them, $100 less at napa and they probably have it in stock. Try a 72 chevelle. The only caveat is make sure the back of the pump has the mounting studs. My first one didn't and I thought a bolt was all that is needed. It slowly leaked for years. When I replaced it it came with the stud mounted on it. It must have the slotted shaft with the woodruff key to match the pulley. The high pressure hose is a direct fit.

The compressor is a common SD508, can get it on ebay, etc for $100-150. If you're going to change to R134 you might as well go with a new compressor, the vtwins from Chrysler are famous for leaking after 2-3 years. You will need one of these to crimp the hose ends:

I posted about this a while back.

cvfracing.com

It's a bit expensive but it works very well and looks awesome. There are a couple versions depending on what accessories you have. Don't buy the pump from them, $100 less at napa and they probably have it in stock. Try a 72 chevelle. The only caveat is make sure the back of the pump has the mounting studs. My first one didn't and I thought a bolt was all that is needed. It slowly leaked for years. When I replaced it it came with the stud mounted on it. It must have the slotted shaft with the woodruff key to match the pulley. The high pressure hose is a direct fit.

The compressor is a common SD508, can get it on ebay, etc for $100-150. If you're going to change to R134 you might as well go with a new compressor, the vtwins from Chrysler are famous for leaking after 2-3 years. You will need one of these to crimp the hose ends:

I posted about this a while back.

John Kirby

Active Member

I should add the bolts on the crank pulley were a bit too long and rubbed on the timing cover. I found ones about 1/4" shorter and it worked fine.

John Kirby

Active Member

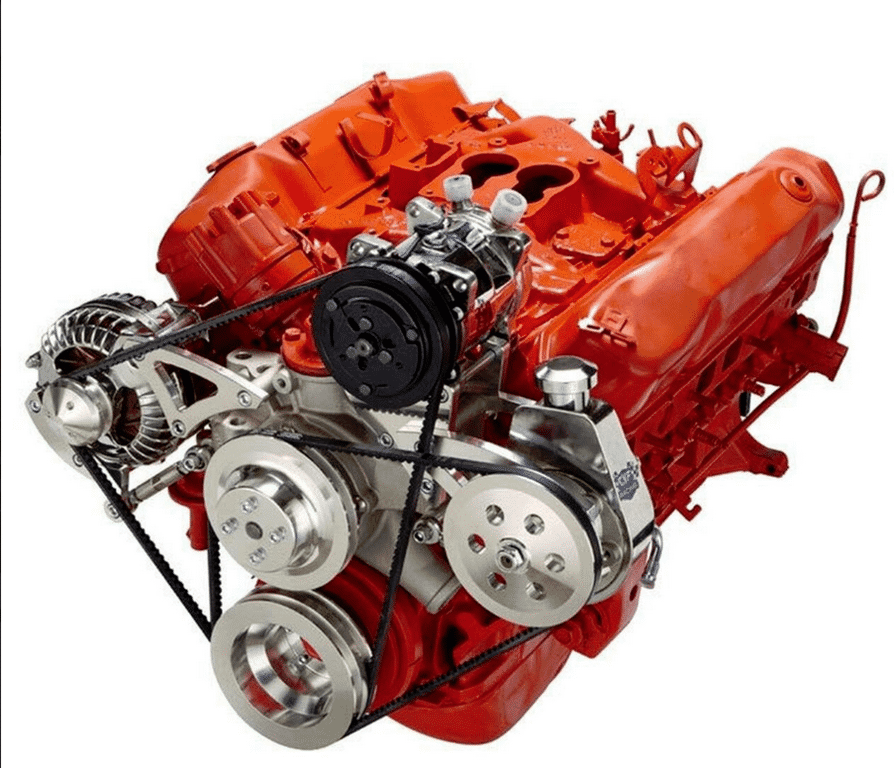

The serpentine version costs a lot more. But it is more reliable. And usually has a belt tensioner that keeps it tight. The only issue I have with the v-belt version is the limited contact with the alternator. There's a reason the original factory design used two belts. As this photo shows:

The dual belts are actually for the air conditioner compressor because they would tend to slip when the compressor was engaged. The same alternator has a single belt pulley when there's no air conditioner.

Similar threads

- Replies

- 12

- Views

- 2K

- Replies

- 8

- Views

- 1K

- Replies

- 2

- Views

- 1K

- Replies

- 18

- Views

- 666