I have been working on my mechanical beasties for many decades. My first many years with crimping wire terminals was simple.....the standard thin plier with an oval shaped hole that just squeezes the terminal to flatten it into the oval shape. I gave it little thought, until the last ten or so years, esp after my work on restoring an MG. So, ventured out into the more robust crimper pliers that have a prong, nib, tit, or something that forces into the crimp for a better grip. Liked them for some of the larger terminals. So, now, on the plymouth wire harness replacement, I thought more of the problems, esp for the open type terminals and special crimpers. So, got a couple types, and found they would not work well. Crimp down the tangs OK but dont grip. Tried the YouTube bit to little avail, and finally went onto the WireFy website, and they show the types of mandrel dies for different types of terminals. What they DO NOT get into is the operation of crimping. So, back into the shop again to try several size terminals and wires, and different crimpers. What I have figured out, with no instruction found yet, it that I can get the new style crimper to close and round the tangs on the terminals, BUT, I then have to go to a smaller size die to finish the crimp and it will actually tighten up on the wire. I am not sure I have it correct yet, but can reproduce a fairly good crimp with the open tang terminal, but have to use two crimps. I may alter my thinking after another set of dies that are on the way....would think this should work in a single crimp. More later on my hateful experience as things progress. I am still trying to figure whether I want to use the old style crimp on the barrel uninsulated couplers, or crunch with the heavy plier that will dimple the fitting......not sure yet. Sometimes adding the crunch of the heavy dimple will open up the terminal which is bad, then it has to be closed back.....not good. Yes, I am old, but how can something so simple, be so complex.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wire terminal crimping lessons

- Thread starter 66furys

- Start date

volksworld

Well-Known Member

i know the feeling...basically i've always used insulated or closed barrel connectors and have the appropriate crimpers for those (klein 1006 and others)...now that i'm trying to get factory appearing crimps on open barrel connectors decided to buy the correct crimpers for B style crimps...what could be so hard about that ? channelock 909s just squashed them....a ratcheting set from amazon was terrible and wouldnt release to try to reset it when it went sideways, a non ratcheting Iwiss set was impossible to squeeze and even when i put it in a vise the results were awful...so now i'm waiting for a $90 set from American Autowire to arrive....i need these to put on new fusebox terminals which are steel along with regular stuff...i see german made stuff out there but refuse to believe i need a $500 tool to get acceptable results

Last edited:

Loadrunner

Active Member

klein 1006

As sold by Snap On, and others. I've been using nothing but for several decades without any issue, just great crimps.

I have learned another lesson the hard way. I had rec'd some nice locking spades for the connectors in my wiring kit, but ordered spares from China. Big mistake. China stuff will work, but not as stout as what was in the kit....maybe Amer Auto Wire....dont know, but have asked. Big difference in the entire install process. Do not recommend the cheap ones for anything....will put mine aside. And too, Volks world, I have tried the same types with the same results you mention.....no fun at all. Also, wish I could afford the Snap boys tools....have a few that are the best, but generally cannot afford them.

Loadrunner

Active Member

I could afford the Snap boys tools....

Snap On "Cry only once."

Seriously, a $35 pair of crimpers.

Loadrunner

Active Member

I learned wiring at automotive school and the later the school of hard knocks, and I still wire for self and others. If there's a better crimper than the Klein, I've never needed it, heard of it, or needed to hear of it.

From the net, well described, maybe too well...

"Best crimpers I've ever used. Although not recommended I've crimped up to 4 gauge wire with these things. I've got big hands and I could see if someone with smaller hands tried to use these they might struggle with larger wire. They are decently weighted so they work good as a threat to your friend who is trying to scare you as you start up your car after working on it... or it also works good to do the scaring. Just tap on the bumper repeatedly when your friend starts their car/truck."

From the net, well described, maybe too well...

"Best crimpers I've ever used. Although not recommended I've crimped up to 4 gauge wire with these things. I've got big hands and I could see if someone with smaller hands tried to use these they might struggle with larger wire. They are decently weighted so they work good as a threat to your friend who is trying to scare you as you start up your car after working on it... or it also works good to do the scaring. Just tap on the bumper repeatedly when your friend starts their car/truck."

Yes, I have looked at these, and have two pair of similar pliers. However, these do not properly crimp the open tang terminal. The open tang has to be curved back onto itself inside a die that fits correctly. This forms the type fitting seen on all OEM wiring harnesses. I will admit that I like this type plier a lot, and will use it when I can on the heavier crimp terminals. Howsumever, this will not work on the terminals that are needed to go into the connector blocks, with the lock tabs. This is just one more type of problem terminal that we have to deal with. Again, if you review the WireFy site, you will see the many types of dies that are needed for the different terminals, that are driving me to have more scotch whiskies this afternoon. Hmmm.

Loadrunner

Active Member

more scotch whiskies

Eureka, it's the solution ;]]]

Last edited:

I don't have a good answer for a good crimper, but I found a really good wire stripper. https://a.co/d/fpipbfJ

Easiest and best wire stripper I've ever used .

Easiest and best wire stripper I've ever used .

And worth every penny. They are forged like a regular pair of pliers and not stamped steel like most electrical pliers.

Back when we had some OEM terminals at the dealership, back in the later 1970s, they appeared to be like the Chrysler terminals in all respects. I know that circular/indented crimp looks neat, but what I ended up doing was to fold one side of the tang flat over the bare wire, then folding the other side on top of the first one. Lots of good wire contact. Usually, with enough pressure, would flatten and spread the wire strands a bit, too. Then I did the same with the rear tangs on the wire insulation. If something better than that was possible, it was to put a dab of hot wire solder on the wire/terminal combination. I never did use the solder, but never had any reliability issues, either.

I later bought a Sears stripper/crimper tool. Worked great for those connectors with the plastic insulators on them. "Solderless connectors". Also worked well on spark plug wire terminals.

Might be a bit "shade tree" for an OEM situation, but it worked for me . . . as long as one of the tangs didn't break off during installation.

Enjoy!

CBODY67

I later bought a Sears stripper/crimper tool. Worked great for those connectors with the plastic insulators on them. "Solderless connectors". Also worked well on spark plug wire terminals.

Might be a bit "shade tree" for an OEM situation, but it worked for me . . . as long as one of the tangs didn't break off during installation.

Enjoy!

CBODY67

Dan Scully

Well-Known Member

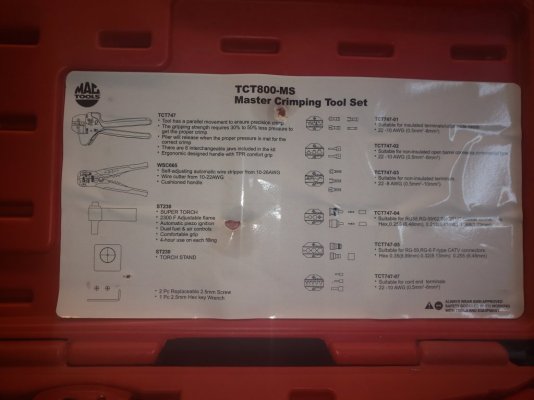

And every crimp is the same. I sold dozens of those sets on the truck. The Delphi type connectors are a bit tricky. It's best to sacrifice a few to get good at it.I bought this set from the tool truck years ago, it does the double crimp like oem . Terminals are a little hard to. come by not impossible .

View attachment 566792View attachment 566793View attachment 566794

That is the ticket.....and necessary if you want to use the plastic connector blocks, and new terminals. I am using the one I got from the painless folks.....works, but not easy. The biggest problem may be with the different types of terminals. The thin china crap is way different than the better quality stuff made here....much heavier and I think easier to deal with. BUT, there are many sizes of the dies for this type crimp, and as Mike said, you need to practice on the size wire and fitting you are using before the real thing. My main problem so far is that every wire is different size on the one connector, and I am losing hair....and have a long way to go on the new harness. Waiting on the new WireFy that is similar to the kit above.

Wonderwagon

Well-Known Member

Amp and Molex, within their catalogs, specify hand tooling for each connector, from the lowly barrel to ring terminal. When the terminal is to be used with a wire with insulation, two factors come into play the wire gauge and insulation thickness. These require a hand tool with a die, that has two different parts the first slightly smaller that crimps the malleabile metal around the bare wire forcing a portion into the strands and around the strands the other portion of the crimp surrounds the insulation to prevent movimento. Yes you can moosh the terminal down with vice grips but the conductivity between the contact and wire is decreased. I deal with mil spec terminals in my work, and find with a little looking can find the correct terminal and tooling to do fiele repairs. Sumation terminal type, wire gauge, insulation, insulated/ non insulated determines tooling for optimal results.

Great points thanks. I did see some expensive molex terminals, but I do not remember finding the types I needed....does not mean they are not available.....I just have not found....will look again. And, I am still looking, esp after today's exercise. Added the female spades with shrink shields. Made, you know where. Appear to be good quality from the outside. Two issues, one was that most of the fittings were either too tight to install or way too loose for connection. Most had to be adjusted for proper tension fit. Not a happy camper, since this was inside the dash for turn signal wires. Heat shrink was not easy either. I am investigating Amer Auto Wire...not done on this quest yet. And to think I was so happy back in the day with the nylon shield connector that just got crimped with the old style crimpers, and call it good. Today, I am losing my mind trying to make it better. It was Russian Admiral Gorshkov who said, Better is the enemy of good enough.

Maybe.

Maybe.

Loadrunner

Active Member

"Voltaire, the French writer, said, “The best is the enemy of the good.” Confucius said, “Better a diamond with a flaw than a pebble without.” And, of course, there’s Shakespeare: “Striving to better, oft we mar what’s well.”

Last edited:

Loadrunner

Active Member

DeTokeville had some amazing insights, makes you wonder what he sampled ;]

Similar threads

- Replies

- 16

- Views

- 928

- Replies

- 13

- Views

- 2K

- Replies

- 2

- Views

- 679

- Replies

- 8

- Views

- 2K