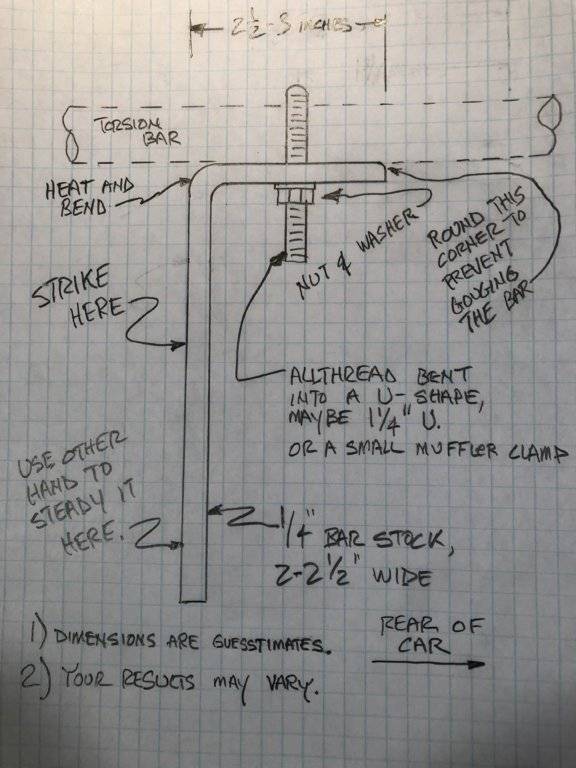

A long time ago I made a tool very similar to what I've sketched here, using scrap I had around the garage. Some beefy bar stock, some all-thread or a muffler clamp, nuts and washers....and a method to bend that bar stock 90 degrees.

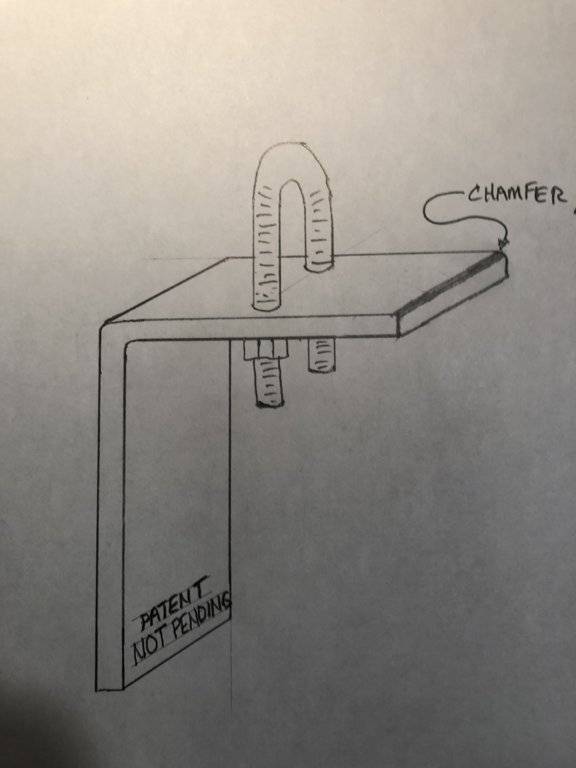

The reason this cheap, shoddy, rickety tool works is that it's "self-tightening" when you hit it, instead of sliding down the torsion bar and annoying the bejeeebus out of you while cursing me for my stupid device. That self-tightening, leverage action is why you must chamfer that corner that touches the bar....that could be a gouge point.

If you find that it does slide on you, shorten the horizontal leg towards the clamp to get more leverage when it's whacked.

If you want to get fancier, add another U clamp. Can't hurt, might help. You're on your own.....

The reason this cheap, shoddy, rickety tool works is that it's "self-tightening" when you hit it, instead of sliding down the torsion bar and annoying the bejeeebus out of you while cursing me for my stupid device. That self-tightening, leverage action is why you must chamfer that corner that touches the bar....that could be a gouge point.

If you find that it does slide on you, shorten the horizontal leg towards the clamp to get more leverage when it's whacked.

If you want to get fancier, add another U clamp. Can't hurt, might help. You're on your own.....