Carl K

Member

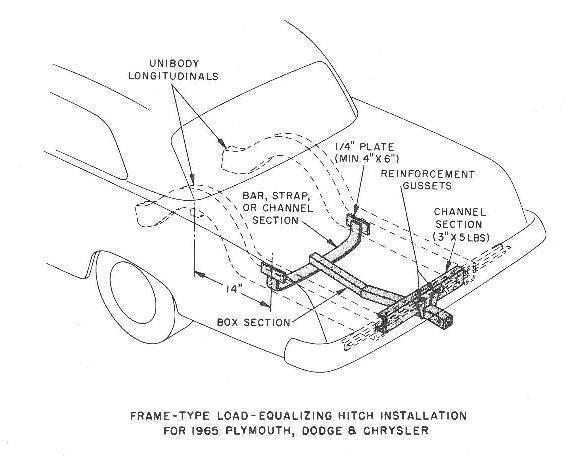

I've finally finished with the tow hitch for my '65 New Yorker. I used the general layout that Chrysler provided to the customers who ordered a tow package.

I didn't want to weld it to the unibody, because knowing my luck I'd need to drop the gas tank. I also wanted to drill as few holes as possible. For the attachment near the rear bumper, I used the four bumper holes. This required a jog in the cross member to clear the fuel tank filler.

My dad milled the slots to match the bumper irons.

The forward loop attaches to the outsides of the unibody "frame rails".

I did drill the "frame rails" for the forward loop but I sleeved the holes so the frame wouldn't crush.

After all seventeen pieces were welded together, it looked like this.

After all seventeen pieces were welded together, it looked like this.

And finally, back from the powdercoater.

Here it is under the car, with all new Grade 5 9/16 fasteners. I haven't put the bumper on yet, but will get a couple shots tomorrow.

It just clears the empty fuel tank, when full it might rest on the hitch but that's okay with me.

It took a long time, mostly because I don't have a MIG welder (TIG only), but I'm really pleased and it turned out nicer than if I would have asked U-Haul to make one for me.

Carl K.

I didn't want to weld it to the unibody, because knowing my luck I'd need to drop the gas tank. I also wanted to drill as few holes as possible. For the attachment near the rear bumper, I used the four bumper holes. This required a jog in the cross member to clear the fuel tank filler.

My dad milled the slots to match the bumper irons.

The forward loop attaches to the outsides of the unibody "frame rails".

I did drill the "frame rails" for the forward loop but I sleeved the holes so the frame wouldn't crush.

And finally, back from the powdercoater.

Here it is under the car, with all new Grade 5 9/16 fasteners. I haven't put the bumper on yet, but will get a couple shots tomorrow.

It just clears the empty fuel tank, when full it might rest on the hitch but that's okay with me.

It took a long time, mostly because I don't have a MIG welder (TIG only), but I'm really pleased and it turned out nicer than if I would have asked U-Haul to make one for me.

Carl K.

Last edited: