fury fan

Old Man with a Hat

No, 'tis correct.

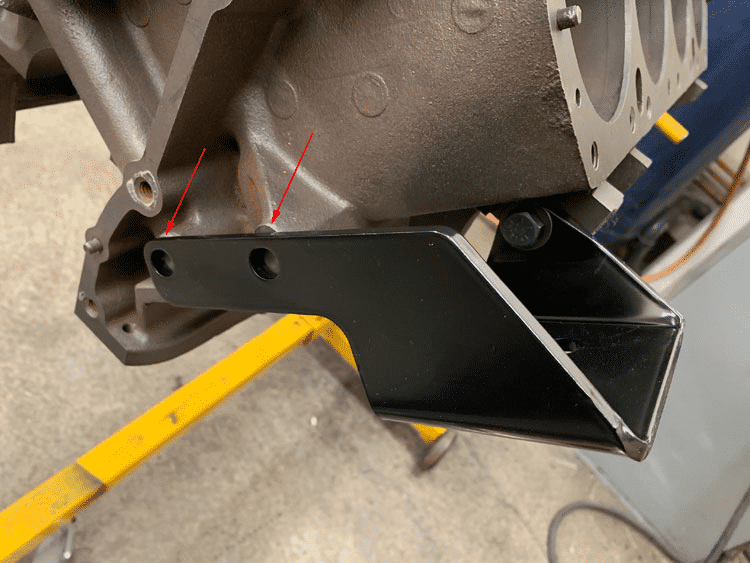

There are 2 types of brackets available nowadays. (I just learned about the 2nd bracket in the last 6 mos)

The one you posted is the OEM style, for engines with the bosses, but modified to use an available insulator (from an early B-body).

The 2nd one is for engines without the bosses.

Both Schumacher and 440Source have webpages for them.

Early C Body 1965 Only-store.440source.com

'67-69 A-Body & '65 C-Body Big Block Left Side Conversion Kit

Presumably the 'oil pump' bracket is made to use the same B-body insulator, but I didn't dig into that.

There are 2 types of brackets available nowadays. (I just learned about the 2nd bracket in the last 6 mos)

The one you posted is the OEM style, for engines with the bosses, but modified to use an available insulator (from an early B-body).

The 2nd one is for engines without the bosses.

Both Schumacher and 440Source have webpages for them.

Early C Body 1965 Only-store.440source.com

'67-69 A-Body & '65 C-Body Big Block Left Side Conversion Kit

Presumably the 'oil pump' bracket is made to use the same B-body insulator, but I didn't dig into that.