Whatta you mean, sliced it with a zip cut? I'm drawing a total blank here.....I've modified 2 of the range rover units. First one i ground it thinner. Made a big mess but it worked. Second one I sliced it with a zip cut.

This worked much better. Took a fraction of the time. Way less mess and less burnt rubber stink.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'66 300 Rag Joint. "am I the crazy one?"

- Thread starter NormanPlombe

- Start date

300rag

It's Not Going to Shift Itself

I'm thinking this...Whatta you mean, sliced it with a zip cut? I'm drawing a total blank here.....

rd92west

plan C

Yea angle grinder with death wheel (zip cut blade)

I clamped the coupler in the vise.

Marked with a sharpy how much I wanted to cut off. Zip cut blade cut thru the rubber and steel with ease.

Then I flipped the coupler over and finished the surgery.

Then drilled the holes deeper so the Allen head bolts were flush.

I never thought to take pictures.

I clamped the coupler in the vise.

Marked with a sharpy how much I wanted to cut off. Zip cut blade cut thru the rubber and steel with ease.

Then I flipped the coupler over and finished the surgery.

Then drilled the holes deeper so the Allen head bolts were flush.

I never thought to take pictures.

Found this. Canadian dollars but still pricy.

1965-73 B & C-Body Steering Column Insulator-Repro

1965-73 B & C-Body Steering Column Insulator-Repro

Last edited:

NormanPlombe

Member

Excellent find...but that price is from another planet, no? I just received my Dorman ones. If they look good I'll live with them. Meantime, we should band together and get an order of 20 of them (I think we could find 20 people on here who need them...pull that heat shield of any 50 year old car and I guarantee the thinks cracked) and see if they'll give us a break.

rd92west

plan C

I agree with your thinking Norman,

I'm all in for the perfect piece. The problem I see is even if they give a 20% discount it's still way more than it's worth.

I got the range rover units from a place called Rovin Farm. Something like 13 bucks each. Maybe 16 cant recall. I seen the part number in a previous post.

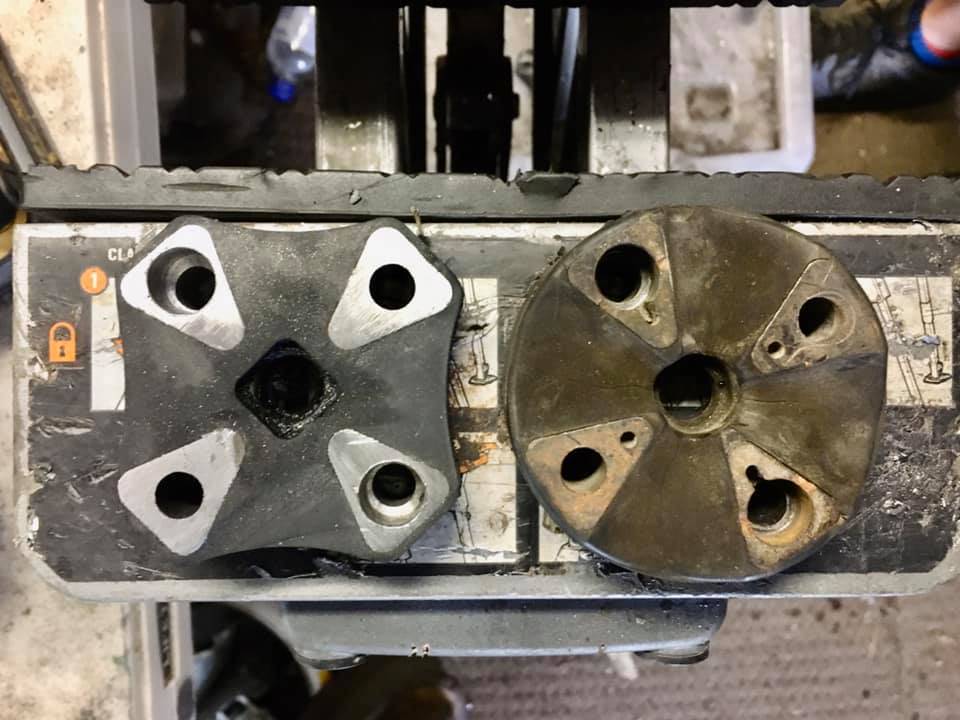

There is 2 difference between these and original.

First is they are aprox 3/8 inch thicker.

And second the rubber is a little stiffer.

Overcoming the first obstacle is pretty easy.

Second obstacle was just a matter of patience.

I'm all in for the perfect piece. The problem I see is even if they give a 20% discount it's still way more than it's worth.

I got the range rover units from a place called Rovin Farm. Something like 13 bucks each. Maybe 16 cant recall. I seen the part number in a previous post.

There is 2 difference between these and original.

First is they are aprox 3/8 inch thicker.

And second the rubber is a little stiffer.

Overcoming the first obstacle is pretty easy.

Second obstacle was just a matter of patience.

NormanPlombe

Member

I might also argue that the way these C bodies (not sure which years, but mine's one of them) had that little kink in the steering shaft is a real design flaw. I don't think this type of joint is good at flexing that way over the long term. I look at mine and it changes direction at the ragjoint rather than the other (whatever it's called) coupler. there should really be a rag joint at the steering box and a hard u joint where the existing rag joint is. As I understand, the later c bodies were designed with straighter alignment of their steering columns.

Clover

Well-Known Member

I used the Range Rover part, without shaving it and it was a tight fit but worked great.Here is a link to my escapades with the steering coupler.... using the British part.

Steering Column Overhaul

If I were to do it again I wouldn't grind it down, just use as-is and the column and steering wheel moves back about 1/4". The only potential problem area would be the shift needle lining up with the cluster.

rd92west

plan C

It couldn't get simpler with everything removed from the car.I used the Range Rover part, without shaving it and it was a tight fit but worked great.

I replaced the coupler with steering column in the car.

The coupler needed a shave to fit in and getting the Allen head bolts installed takes some patience due to the coupler needing to flex for the misalignment

TerryM

Active Member

I modified the range rover one. It works nice

It's better in a letter

New Member

I use conveyor belt material. It can be drilled, punched, and cut with a hacksaw, bandsaw, or reciprocating saw. I also use it for exhaust hangers, mudflaps, and any place a strong, flexible, sound insulating, connection is needed.

NormanPlombe

Member

DAMN! That stuff sounds durable! I think they make labiae out of it.I use conveyor belt material. It can be drilled, punched, and cut with a hacksaw, bandsaw, or reciprocating saw. I also use it for exhaust hangers, mudflaps, and any place a strong, flexible, sound insulating, connection is needed.

To Tony's comment about measuring the effort to turn the steering wheel. Yes, there is a contraption that is affixed to the steering wheel, with springs, to measure the force needed to turn the wheel. Might even be shown in the FSM? Or some YouTube videos or Chrysler MasterTech videos.

From what I remember seeing, the "heat shield" is really "gravel shield" that was federally-mandated as some vehicles had had issues steering the vehicle when gravel would get lodged in the lower part of the column. Whatever it really is called is in the FSM in the area of "changing spark plugs", as they indicate to remove it to change #7 plug. Then re-install it when done.

On our '66 Newport 383 2bbl, I did the removal to change #7, then put it back on, like the FSM indicated. After that, I just left it off with NO issues in longevity or similar. BUT, the car is used normally and not raced or any other HD service use, so exhaust manifold radiation is NOT an issue. On the other hand, there is plenty enough of free air space under the hood of a '65-'66 C-body (pre-collapsible steering column years) to cool things down, it seems to me. Always made sure to have a good fan clutch in the mix, too. Just my experiences, FWIW.

Happy Holidays!

CBODY67

From what I remember seeing, the "heat shield" is really "gravel shield" that was federally-mandated as some vehicles had had issues steering the vehicle when gravel would get lodged in the lower part of the column. Whatever it really is called is in the FSM in the area of "changing spark plugs", as they indicate to remove it to change #7 plug. Then re-install it when done.

On our '66 Newport 383 2bbl, I did the removal to change #7, then put it back on, like the FSM indicated. After that, I just left it off with NO issues in longevity or similar. BUT, the car is used normally and not raced or any other HD service use, so exhaust manifold radiation is NOT an issue. On the other hand, there is plenty enough of free air space under the hood of a '65-'66 C-body (pre-collapsible steering column years) to cool things down, it seems to me. Always made sure to have a good fan clutch in the mix, too. Just my experiences, FWIW.

Happy Holidays!

CBODY67

Mike66Chryslers

Senior Member

I doubt that the metal shield over the rubber steering coupler was to prevent it from gravel or other road debris. that is the first I ever heard of that idea. In 1966 the shield is mostly above the coupler, not below it, where gravel kicked up off the road would come from. It wasn't until later years that the shield was redesigned as a ring around the coupler. If gravel got up that high under the hood you'd have bigger problems!To Tony's comment about measuring the effort to turn the steering wheel. Yes, there is a contraption that is affixed to the steering wheel, with springs, to measure the force needed to turn the wheel. Might even be shown in the FSM? Or some YouTube videos or Chrysler MasterTech videos.

From what I remember seeing, the "heat shield" is really "gravel shield" that was federally-mandated as some vehicles had had issues steering the vehicle when gravel would get lodged in the lower part of the column. Whatever it really is called is in the FSM in the area of "changing spark plugs", as they indicate to remove it to change #7 plug. Then re-install it when done.

On our '66 Newport 383 2bbl, I did the removal to change #7, then put it back on, like the FSM indicated. After that, I just left it off with NO issues in longevity or similar. BUT, the car is used normally and not raced or any other HD service use, so exhaust manifold radiation is NOT an issue. On the other hand, there is plenty enough of free air space under the hood of a '65-'66 C-body (pre-collapsible steering column years) to cool things down, it seems to me. Always made sure to have a good fan clutch in the mix, too. Just my experiences, FWIW.

Happy Holidays!

CBODY67

The rubber steering coupler in my hardtop was worn out but still flexible. It still had the metal heat shield over it when I got the car. The one in my convertible looked like it had been baked in the oven! Someone had removed the heat shield prior to my ownership. Anecdotal evidence, but you may not know if you're harming it for years.

As for the exhaust manifolds not radiating enough heat in a "normal" car, I have a story about my convertible when it started running rich. The air cleaner element got clogged with sanding dust when it was at the bodyshop and I didn't notice right away. The extra heat in the exhaust manifolds was enough to MELT two plastic plugs that I had installed in the firewall to plug holes left from removing an aftermarket A/C system. They were further away from the exhaust manifold than the steering coupler is.

Similar threads

- Locked

- Replies

- 17

- Views

- 6K