Do you have the ability to draw a vacuum on the system? That's a critical step you must do to eliminate the moisture guaranteed to be in the system when you replace any parts before charging.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

66 Monaco Wagon Preservation

- Thread starter TxDon

- Start date

TxDon

Well-Known Member

Yes, a vacuum pump is on my tool list.Do you have the ability to draw a vacuum on the system? That's a critical step you must do to eliminate the moisture guaranteed to be in the system when you replace any parts before charging.

It needs to be the right kind for AC servicing. Good luck - I'm watching with interest!

TxDon

Well-Known Member

I have ordered and received a new filter dryer and new front expansion valve, both 4 Seasons. I also ordered a gauge set, vacuum pump and a bunch of DuPont R134A from Amazon which should arrive next week. My O'Reilly's down the street netted the new charge fittings, O-rings, a probe thermometer and a can tap. I already own a digital scale. I'm still working on flush and leak check equipment and will need refrigerant oil. I see that PAG oil is sold in 3 different viscosities, would I be correct in assuming the heavier weight is better for my old compressor?

I don't know about the PAG oil viscosity...

bigmoparjeff

Senior Member

OK, I've heard of that on GM cars, nothing like that is mentioned in the shop manual for the 66.

The RV-2 compressor doesn't need a low pressure cut off switch because it's splash lubricated from the oil reservoir at the bottom of the unit, just like an air compressor or lawn mower engine. All other A/C compressors rely on oil mist carried by the refrigerant for lubrication, and will burn up if run too low on charge.

Jeff

bigmoparjeff

Senior Member

I see that PAG oil is sold in 3 different viscosities, would I be correct in assuming the heavier weight is better for my old compressor?

I think that's a safe assumption.

Jeff

TxDon

Well-Known Member

Well my A/C adventure has taken a whole new turn. I had been operating on the assumption that the system was empty or nearly so due to the car sitting nearly unused for about 4 years. When I got my gauge set I hooked it up to the R12 fittings just to see and was surprised at about 40 psi cold and about 125 high side running! After talking to some car buddies and doing a little more research I decided to try a simple top-off before jumping into a partial rebuild.

I followed the shop manual, hooked everything up and warmed up the car, both A/c units on max with all windows down. I started charging and everything reacted normally, wound up taking 2 1/2 cans of R134 plus a 2 ounce oil charge. I filled it by pressure, about 48 low and 260 high on a 95 degree day, the low end of the recommended scale. Cool air came back slowly then got really cold out of both units, 45 degrees at the vent. I took it out for a ride and had to turn it down because I was getting cold!

So for now I'm going to put the rest of the parts and tools away and see if the charge holds and everything keeps working, I'll keep you posted.

I followed the shop manual, hooked everything up and warmed up the car, both A/c units on max with all windows down. I started charging and everything reacted normally, wound up taking 2 1/2 cans of R134 plus a 2 ounce oil charge. I filled it by pressure, about 48 low and 260 high on a 95 degree day, the low end of the recommended scale. Cool air came back slowly then got really cold out of both units, 45 degrees at the vent. I took it out for a ride and had to turn it down because I was getting cold!

So for now I'm going to put the rest of the parts and tools away and see if the charge holds and everything keeps working, I'll keep you posted.

TxDon

Well-Known Member

Well, I'm pissed. After exactly one month of cold air conditioned comfort my compressor crapped out yesterday so I am back to where I started. I can't really say I'm surprised but I was really hoping to get at least the rest of the summer out of the system. So now I'm back to my original plan with the addition of a new compressor. I'm going to concentrate on the carb rebuild and engine tuneup first then worry about the A/c later.

That's too bad... do you know which component failed? Dye test will determine a leak if you added it during the recharge...

Did the compressor fail? Ultimately, now that you're familiar with AC systems and their basic components, then you have a much better chance at fixing it properly. Once it's good, it's usually rock solid for years. My 66 T&C wagon is a great example that - little top ups every 2 years or so, and otherwise reliable.

Did the compressor fail? Ultimately, now that you're familiar with AC systems and their basic components, then you have a much better chance at fixing it properly. Once it's good, it's usually rock solid for years. My 66 T&C wagon is a great example that - little top ups every 2 years or so, and otherwise reliable.

TxDon

Well-Known Member

The compressor is clattering like an SOB. It worked perfectly right up to the end so everything was working fine. Unfortunately due to a well insulated cabin and my lousy hearing I did not hear it until it was too late.

Likely just need to rebuild or replace the compressor and dryer - keep in mind that you'll need to completely flush the system as thoroughly as possible to get all the metal filings that may be present from the failed compressor.

Another thing - if your compressor can't be rebuilt, while replacement units are plentiful and reasonably affordable, there are two castings that are unfortunately listed under the same part number - you want the one with 3 mounting bracket holes - there's a plentiful casting with out there with 2 holes which whole it will technically bolt in, with one support bracket not there IMO it isn't good enough. Be persistent and insistent. I ran into this problem with Rock Auto and finally had to climb up their corporate ladder and get 4 Seasons involved to find the right ones. They're out there.

If you need help let me know and I'll put you in touch with the very helpful chap at 4 Seasons.

Another thing - if your compressor can't be rebuilt, while replacement units are plentiful and reasonably affordable, there are two castings that are unfortunately listed under the same part number - you want the one with 3 mounting bracket holes - there's a plentiful casting with out there with 2 holes which whole it will technically bolt in, with one support bracket not there IMO it isn't good enough. Be persistent and insistent. I ran into this problem with Rock Auto and finally had to climb up their corporate ladder and get 4 Seasons involved to find the right ones. They're out there.

If you need help let me know and I'll put you in touch with the very helpful chap at 4 Seasons.

TxDon

Well-Known Member

Thanks Ross, that's good to know. There is now a Summit Racing store near me in DFW and I may deal with them, they list 4 seasons items. Does 4 Seasons rebuilt stuff have a good reputation?

Some say yes some say no. My experience has been good.

TxDon

Well-Known Member

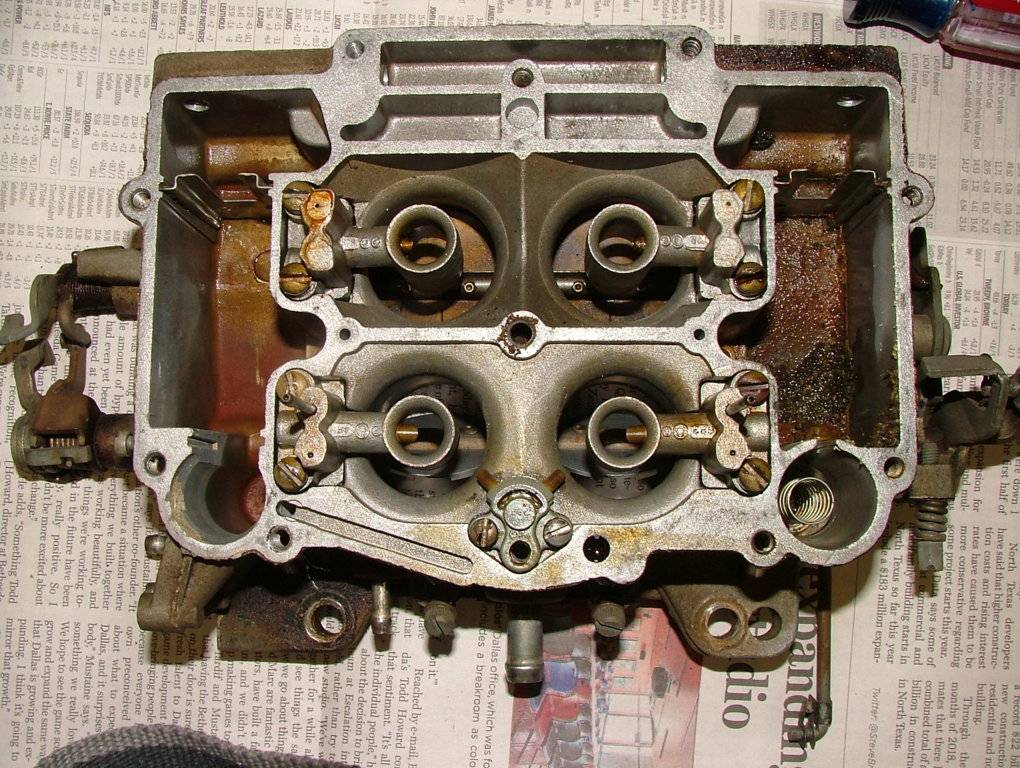

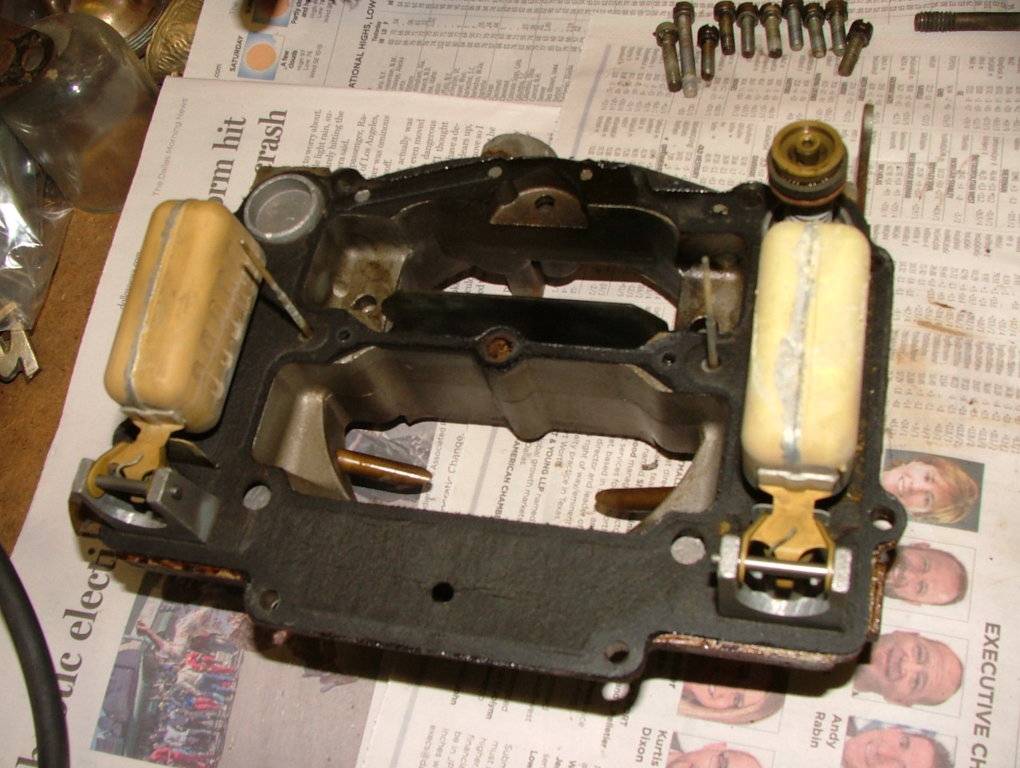

Setting the A/C issues aside for now, I've started my carb rebuild. I took it off the car and disassembled it, found some interesting issues. The accelerator pump and the choke unloader were both shot so someone had bent the sh-t out of the linkage so the choke plate stayed half closed all the time. This richened the mixture and crutched the missing pump shot. This wise move locked out the secondaries so they had not opened in a looong time and were gummed shut. The inside of the carb was actually pretty clean except there was a pile of what looked like coffee grounds in the bottom of one float chamber. When I see stuff like this I'm always amazed the car ran as well as it did - also a testament to the AFB design. Next, cleanup and reassembly.

Yikes! Yup, first things first.

TxDon

Well-Known Member

I took the carb apart and cleaned it up using aerosol carb cleaner and an air hose, it actually was fairly clean other than that gunk pile shown above. I started with an old can of STP carb cleaner but quickly switched to my old favorite Gumout. It worked much faster and dried quickly. I put it together using a kit from Daytona Parts plus two new floats, a rebuilt choke unloader, and a NORS well choke unit. The kit included new Daytona inlet valves using a flat shutoff instead of the stock cone shape, have not used this design before. What took me the most time was trying to get the choke linkage reset as the PO had really screwed it up, glad the FSM had plenty of pics. I put it on the car and started it but it did not work well at all, the choke is binding somewhere and it is not running smooth at all - unfortunately I ran out of time. Still on the drawing board...

TxDon

Well-Known Member

A few more carb pictures.

Choke plate may need new bushings if it's binding up...

TxDon

Well-Known Member

No, the bind was in the well choke connection, all moves free when that is disconnected. I started it again with the choke open, it ran a little better when it warmed up but still has an unstable idle and runs too rich. Carb is back off for another look inside.Choke plate may need new bushings if it's binding up...

Similar threads

- Replies

- 0

- Views

- 207

- Replies

- 6

- Views

- 1K

- Replies

- 5

- Views

- 739