knight_hwk

New Member

Hi all, I'm new to the forum but have been reading threads over the past few months pertaining to minor things I've had to fix on my 66 Polara. sorry for the wall of text, but there is one issue that I have not been able to find any info on, at least anything that I could connect to my specific problem. Here's my problem:

The power windows don't work properly. Simple, right? I couldn't tell you because I have no idea what's wrong... I'm not a mechanic, engineer, or electrician.

All of the windows will move down about 5 inches before they slow down and eventually stop. Going back up is different, sometimes they just don't move at all. This summer, I rolled the passenger window all the way down and it wouldn't come back up no matter what I did. However, the next time I started it (only a few days later) it was able to push itself all the way back up. The thing is, this problem affects all 4 windows.

This leads me to a few questions. Can a bad motor or window regulator have an effect on the other windows in the car? Is it reasonable to assume that they all went bad at the same time? Could it be something wrong with a circuit breaker?

My FSM doesn't have any valuable information about the power windows, nor do the wiring diagrams show the window circuit breaker. I read a post a while back about the breaker being the same for the top, windows, and seat. I haven't noticed any problems with the top but the power seat won't move forward; only back, up, and down. It seems like it wouldn't be connected to the same breaker if they aren't all having similar issues.

One last bit of info is that the ammeter needle will go up when I hit the window switches rather than down like every other accessory. I don't think that they could be wired incorrectly as the wiring hasn't been touched since I got the car in 2015 and the windows only stopped working this year.

There was a problem with the voltage regulator. The battery was showing higher voltage output than it should have and the ammeter was hanging more towards the C than the middle, there was also some flickering of the interior lights and dash. So I replaced that and now it sits right in the middle and no longer has those problems. But, it didn't fix the windows. That's pretty much everything pertaining to the situation.

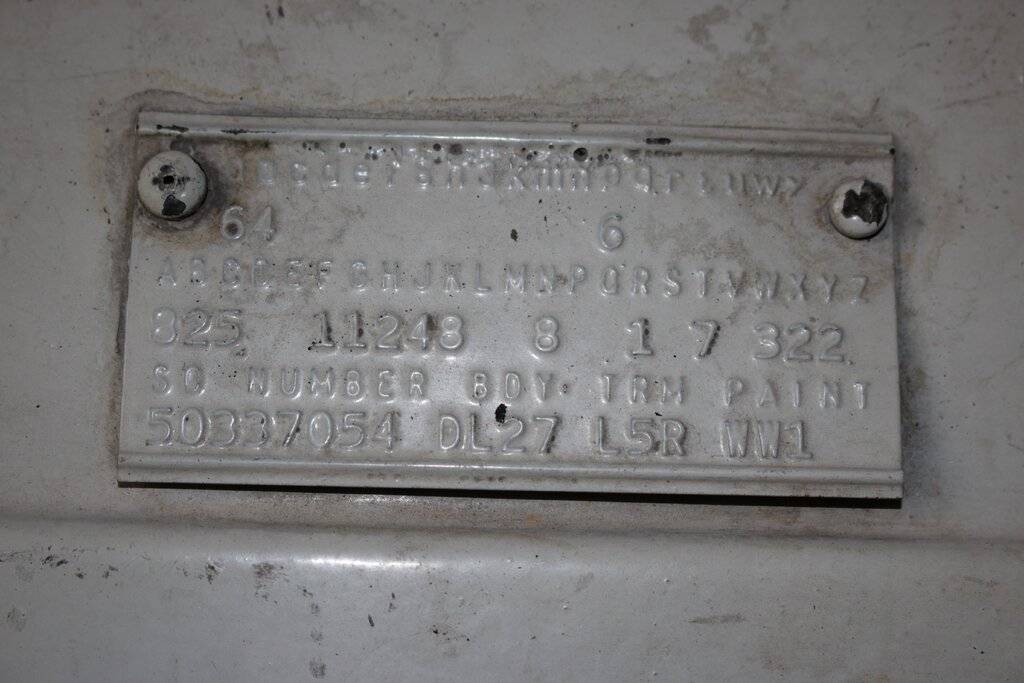

This post ended up much longer than I expected so I'll add some pictures to make up for the great wall of text.

She's a Convertible 500 with a 440 and she's never left Big Sky Country. I inherited it from my uncle after he passed away. He loved this car and I want to take proper care of it in his stead.

The power windows don't work properly. Simple, right? I couldn't tell you because I have no idea what's wrong... I'm not a mechanic, engineer, or electrician.

All of the windows will move down about 5 inches before they slow down and eventually stop. Going back up is different, sometimes they just don't move at all. This summer, I rolled the passenger window all the way down and it wouldn't come back up no matter what I did. However, the next time I started it (only a few days later) it was able to push itself all the way back up. The thing is, this problem affects all 4 windows.

This leads me to a few questions. Can a bad motor or window regulator have an effect on the other windows in the car? Is it reasonable to assume that they all went bad at the same time? Could it be something wrong with a circuit breaker?

My FSM doesn't have any valuable information about the power windows, nor do the wiring diagrams show the window circuit breaker. I read a post a while back about the breaker being the same for the top, windows, and seat. I haven't noticed any problems with the top but the power seat won't move forward; only back, up, and down. It seems like it wouldn't be connected to the same breaker if they aren't all having similar issues.

One last bit of info is that the ammeter needle will go up when I hit the window switches rather than down like every other accessory. I don't think that they could be wired incorrectly as the wiring hasn't been touched since I got the car in 2015 and the windows only stopped working this year.

There was a problem with the voltage regulator. The battery was showing higher voltage output than it should have and the ammeter was hanging more towards the C than the middle, there was also some flickering of the interior lights and dash. So I replaced that and now it sits right in the middle and no longer has those problems. But, it didn't fix the windows. That's pretty much everything pertaining to the situation.

This post ended up much longer than I expected so I'll add some pictures to make up for the great wall of text.

She's a Convertible 500 with a 440 and she's never left Big Sky Country. I inherited it from my uncle after he passed away. He loved this car and I want to take proper care of it in his stead.