OK lets start by saying I started this car over 34 years ago it was a long haul trying to figure it how to but it together so you can get a good laugh on some of the stuff I did to get it up and together . I ended up with three 72 Colts , one out a back yard for $75.00 next 2 from a friend up the street how tried to piece a stock one together to drive , both for $200.00 . One of them would start but would die when you turned the key loose . Two days later I drive by his house and had it running , put a toggle switch from the battery to coil with a resistor , was up and running . perfect body , wife ran it into neighbors ditch while talking to her new puppy in the back seat . pieced it back together with rusty parts for the other one and she drove it for 6 months before getting her a new car . I worked for a water well drilling co . Learned to stick weld while working there , the dana 60 rear came form one of the service trucks , out side bearing went out and they threw the housing away in the scrap pile , asked if I could have It , sure if you can load it ...they are heavy .. cut it down with a 4 inch tubing cutter we used at work to cut pipe with . shortened and welded n strange ends with my 225 stick welder . In fact the whole car was done with a stick welder . I do not have any pic's of the rear frame I built or of how the 36 inch ladder bar setup was stick welded in place.

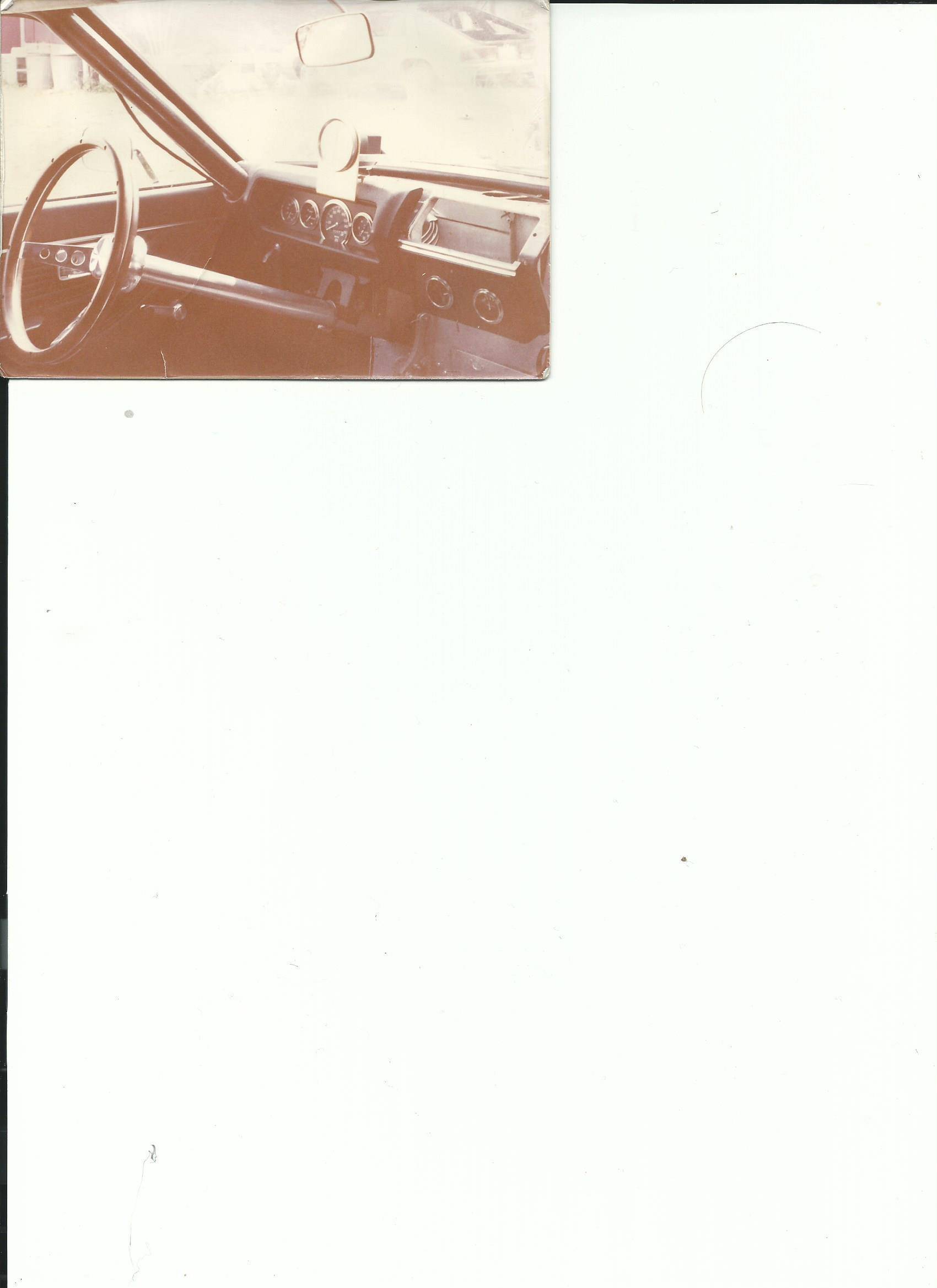

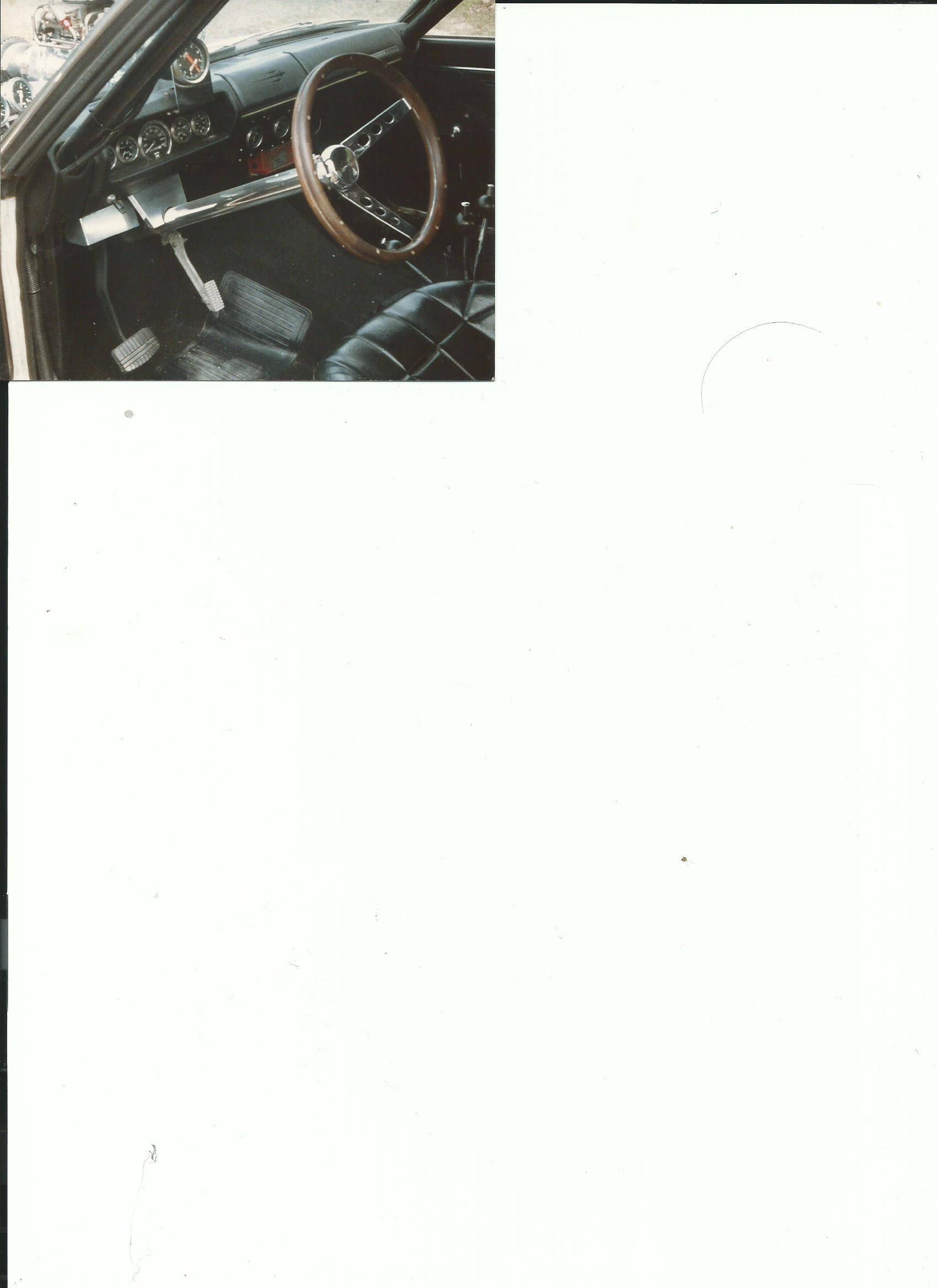

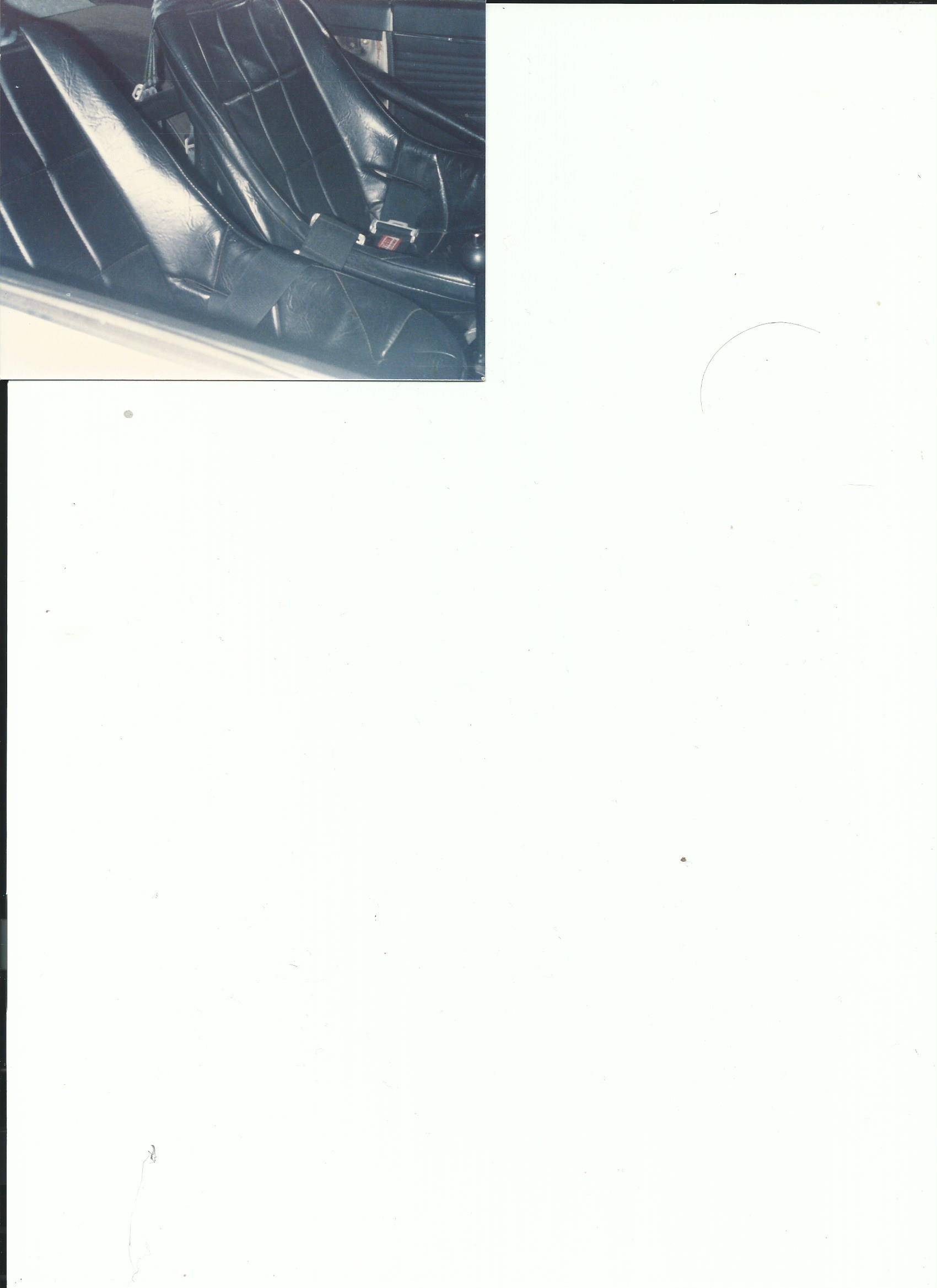

So the first pic shows that I took the firewall out and placed the motor in place where I wanted it and just built the rest of the car around it . Used Hedman headers had to cut and move 2 tubes to get every thing inside the sheetmetal firewall .pic 2 you can see a little more sheet metal work , had no metal brake so I used a 6 inch I beam and a big hammer , crude but effective ..3 pic you can see firewall , used a lot of pop rivets to hold it together . The motor in this thing was moved back 14 inches , cowl was notched almost to the windshield . Next pic shows finished product Msd6al was mounted on the trans tunnel . Take note in pic's I ran rollcage thru the fresh air vents . By the way the cage was made from 2 inch black steel pipe that I got from my work place .. used pvc pipe for a pattern for the bends and the muffler shop bent it for me for 50 cents a bend , see I told you I was cheap . next pic shows seats and if you look real close you can see the rear tire tubs , you could sit it the seat reach back put our hand on the rear tub and then put your foot on the front one . small inside . next I used an ARC control box with switches to start it up and run fans and fuel pumps ect. Next pic shows motor placement , used motor plates , take note U can see road sign I used for firewall .. redneck anyone ? Look at the strut tower , I moved the top of the strut rod over 3 inches and the lower control arm in 3 inches and used 1000 lbs helper springs to hold up the front end , had to do this so tire would not rub fenders . Flipped the struts from rear steer to ft. steer used a MGB rack set up .Redrilled the stock rotors for 4 1/5 bolt pattern . used stock brakes ,with std dodge rear drums in back . used a mopar master cyl. mounted under the dash with stock petal assem. I used what I had . Next pic looks a little better tin work in place . Will post this file getting to big to down load