blackblazer717

New Member

this may be a difficult request but could use some help.

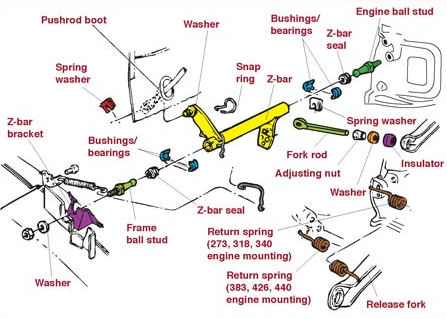

im not sure if anyone else has tried this creation yet or not but im in the process of installing a A833 in a 68 Fury III SMALL BLOCK car. I used a bell from a 69 a body the trans is from a 66 b -body. all if fine an well except I cant get the clutch linkage sorted out. I have / had a z bar from a big block 4 speed c body. but the pivot arm on the bell housing side was was to short to meet up with the clutch fork so I cut that end off and extended it with a piece of a truck z bar to make the the length (added 3") for a total of 4 1/2' from z bar tube to pivot point. needless to say with my creation installed and the opposite end being only 1 1/2" long the pedal pressure was so high I couldn't push it down (mostly due to the extreme difference in both ends of the bar). so im at a loss for an answer.

anyone ever build a small block 4 speed car? and have a solution BECIDES hydro??? I really don't want to but up the firewall to do hydro.

thanks, and sorry for long post

LUKE

im not sure if anyone else has tried this creation yet or not but im in the process of installing a A833 in a 68 Fury III SMALL BLOCK car. I used a bell from a 69 a body the trans is from a 66 b -body. all if fine an well except I cant get the clutch linkage sorted out. I have / had a z bar from a big block 4 speed c body. but the pivot arm on the bell housing side was was to short to meet up with the clutch fork so I cut that end off and extended it with a piece of a truck z bar to make the the length (added 3") for a total of 4 1/2' from z bar tube to pivot point. needless to say with my creation installed and the opposite end being only 1 1/2" long the pedal pressure was so high I couldn't push it down (mostly due to the extreme difference in both ends of the bar). so im at a loss for an answer.

anyone ever build a small block 4 speed car? and have a solution BECIDES hydro??? I really don't want to but up the firewall to do hydro.

thanks, and sorry for long post

LUKE