3175375

Old Man with a Hat

Yesterday, I took a stab at recharging the air conditioning on my 69 Fury III vert - Shamu.

It had about 25 psi of pressure at rest. I hooked up the line gauges (per the markings on the compressor- doofus #2 - I’ll describe #1 later) and proceeded to add some Freon (R-12).

I noticed that the pressures appeared to be backwards - that I was seeing higher pressures on the low side vs. the high side.

I swapped the blue and red hoses and the pressures looked more reasonable - figuring that I had incorrectly attached them - in haste.

Pressures started rising and the compressor started kicking in. I added more and the compressor finally got to where it was running continuously, but the high side pressure was really high, nearly 350 psi. I proceeded to add more as I thought that the system would settle down - boom! The suction (low) side hose blew, spewing oil all over the inner fender well on the passenger side.

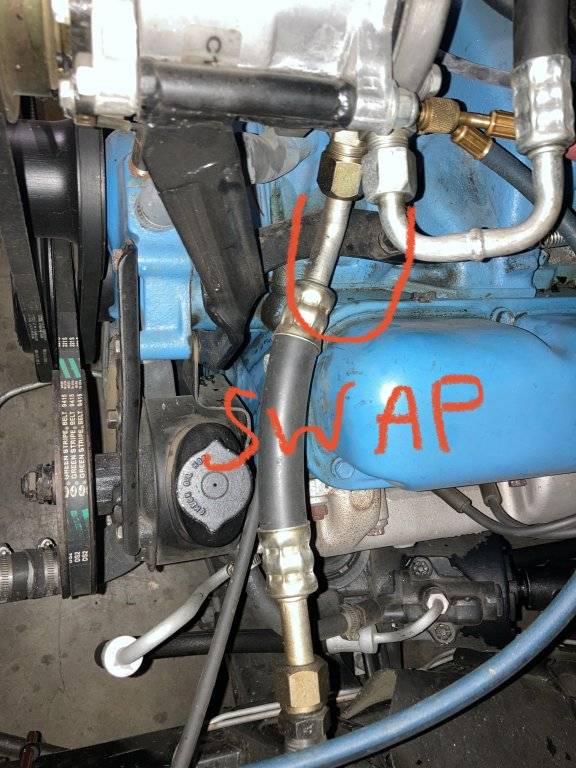

I regrouped and inspected the hoses. I learned that the system was connected to the compressor backwards! This floored me as the previous owner purposely attached them (beautifully) bass-ackwards! (I suspect ignorantly - doofus #1).

So after chatting with my cousin, who runs a heating and cooling company, I indeed determined that the lines were attached backwards. The scroll compressor worked, but I learned that it would not have cooled itself properly as the compressor sloshes the oil inside it when rotating correctly and wouldn’t when running backwards.

My cousin told me about a shop in Sioux Falls that will make up custom hoses (I can’t just swap the compressor ends as they are different sizes).

I will remove both side (high and low) and take them to the shop to be remade correctly.

I think that they can reterminate the low side hose on the compressor side of the drier, but I will discuss with the technician that will do the work.

More to come…

It had about 25 psi of pressure at rest. I hooked up the line gauges (per the markings on the compressor- doofus #2 - I’ll describe #1 later) and proceeded to add some Freon (R-12).

I noticed that the pressures appeared to be backwards - that I was seeing higher pressures on the low side vs. the high side.

I swapped the blue and red hoses and the pressures looked more reasonable - figuring that I had incorrectly attached them - in haste.

Pressures started rising and the compressor started kicking in. I added more and the compressor finally got to where it was running continuously, but the high side pressure was really high, nearly 350 psi. I proceeded to add more as I thought that the system would settle down - boom! The suction (low) side hose blew, spewing oil all over the inner fender well on the passenger side.

I regrouped and inspected the hoses. I learned that the system was connected to the compressor backwards! This floored me as the previous owner purposely attached them (beautifully) bass-ackwards! (I suspect ignorantly - doofus #1).

So after chatting with my cousin, who runs a heating and cooling company, I indeed determined that the lines were attached backwards. The scroll compressor worked, but I learned that it would not have cooled itself properly as the compressor sloshes the oil inside it when rotating correctly and wouldn’t when running backwards.

My cousin told me about a shop in Sioux Falls that will make up custom hoses (I can’t just swap the compressor ends as they are different sizes).

I will remove both side (high and low) and take them to the shop to be remade correctly.

I think that they can reterminate the low side hose on the compressor side of the drier, but I will discuss with the technician that will do the work.

More to come…