Can you say glutton for punishment??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Epic 68 Polara bench seat rebuild for originality

- Thread starter HWYCRZR

- Start date

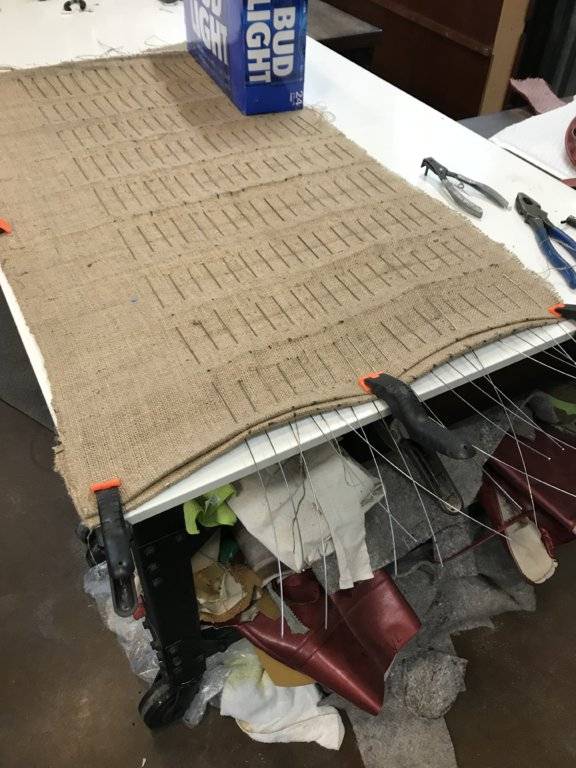

Front seat wires complete and installed.

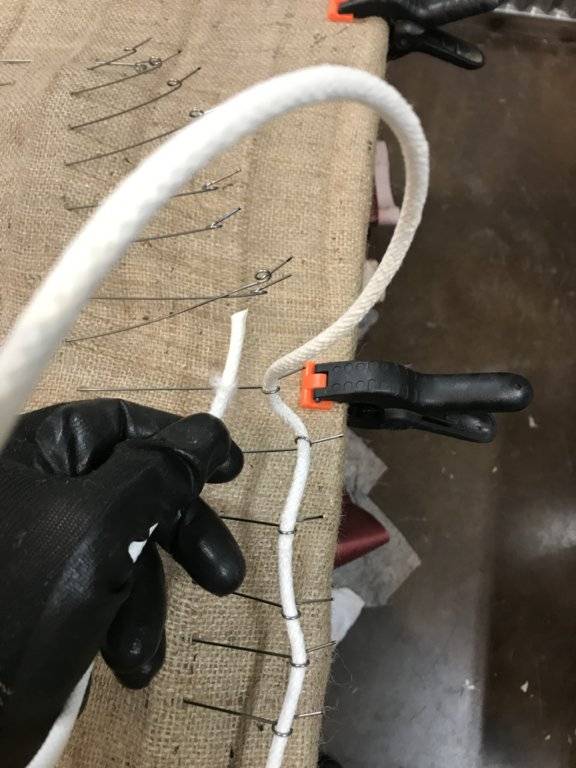

Another thing I learned is to mark where you want the wire to enter and exit. Also along the pleats. With the wire still having a little circular cast it wants to pull it diagonal. The little circles are the perfect size to thread my cord through. Then I put vice grips on one side and pull on the tail with lineman’s pliers to cinch it tight.

Finally success. The other seats will go a lot faster.

Another thing I learned is to mark where you want the wire to enter and exit. Also along the pleats. With the wire still having a little circular cast it wants to pull it diagonal. The little circles are the perfect size to thread my cord through. Then I put vice grips on one side and pull on the tail with lineman’s pliers to cinch it tight.

Finally success. The other seats will go a lot faster.

Rear seat strung and attached. Enough for this weekend. I need to add some dampener insulation underneath the front indent of the rear bench. This one also gets some side insulation around the front and sides. I should order my foam tonight. Maybe I will have it by next weekend.

I think I am in about 77 hours not counting R&D

I think I am in about 77 hours not counting R&D

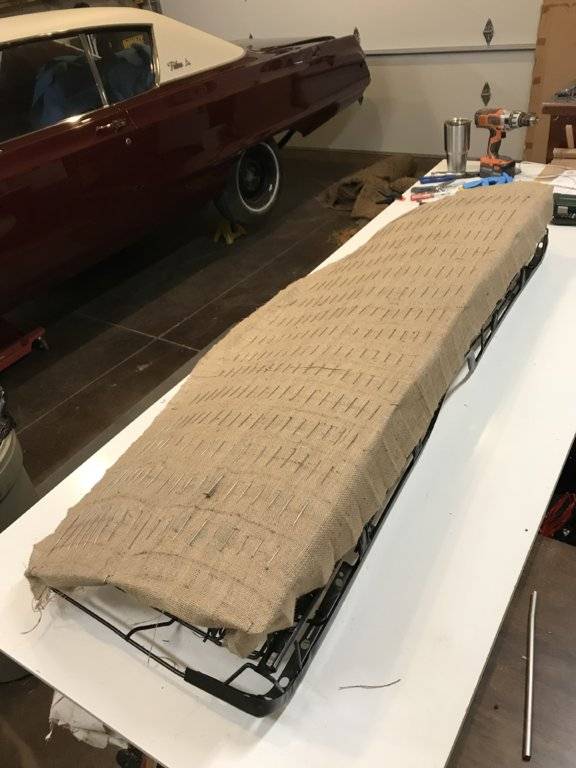

Threaded and done stringing wire. Wow if I would have walked into this knowing that it would have been this difficult, I probably would have taken a short cut and done it differently.

But I got it figured out and at least have the satisfaction of knowing that it is like the factory intended.

About 88 hours into this.

The most time consuming part is threading and crimping the wires. The rear back seat has 23 wires, so 46 eyelets to create, thread cord and pull wire tight around the cord.

Goal is to get my seatbacks ready for covers today. Foam for the benches should arrive tomorrow.

But I got it figured out and at least have the satisfaction of knowing that it is like the factory intended.

About 88 hours into this.

The most time consuming part is threading and crimping the wires. The rear back seat has 23 wires, so 46 eyelets to create, thread cord and pull wire tight around the cord.

Goal is to get my seatbacks ready for covers today. Foam for the benches should arrive tomorrow.

Life saver.

Thanks @Polara_500

I should have my vent cables back in during the next couple of weeks and can send back.

Unless you are coming town for Thanksgiving or Christmas and want to check out the car.

Thanks @Polara_500

I should have my vent cables back in during the next couple of weeks and can send back.

Unless you are coming town for Thanksgiving or Christmas and want to check out the car.

Looking good, man....... Not in a big rush to get it back, haven't used it for about 20 years, (actually surprised I could find it), as long as you're offering an inspection I may have to take you up on that.

Back seat back rest ready for covers. Almost..

Need some offset hog ring pliers to grab a little more of the padding.

Had to put it in and try it. It is soft, but cannot feel the springs behind it. I am sure it will stiffen up when whet the vinyl with the 1/2” foam stitched up.

Need some offset hog ring pliers to grab a little more of the padding.

Had to put it in and try it. It is soft, but cannot feel the springs behind it. I am sure it will stiffen up when whet the vinyl with the 1/2” foam stitched up.

90 hours into it.

If the spring wire burlap was pre- made, I would probably have 45 hours or so into it. I will have to go back and look at my time notes.

Working on the finer details of the rear bench prepping it for covers. I will bore you with detail pictures.

Every thing is the way the originals were.

Added “silencing”inserts to the front of the rear frame. It is to help keep the kids from bottoming out on the big bumps. Jute insulation/ padding.

This is for the person riding the hump. The foam is your only suspension.

Edge protection for the foam. The rear bench only has foam there is no cotton batting on the rear bench. Jute insulation/ padding.

Adding light canvas hog ring support strips to rear of foam. Like the original this helps keep the hog rings from pulling through the foam. Used spray adhesive no. 77 to adhere.

If the spring wire burlap was pre- made, I would probably have 45 hours or so into it. I will have to go back and look at my time notes.

Working on the finer details of the rear bench prepping it for covers. I will bore you with detail pictures.

Every thing is the way the originals were.

Added “silencing”inserts to the front of the rear frame. It is to help keep the kids from bottoming out on the big bumps. Jute insulation/ padding.

This is for the person riding the hump. The foam is your only suspension.

Edge protection for the foam. The rear bench only has foam there is no cotton batting on the rear bench. Jute insulation/ padding.

Adding light canvas hog ring support strips to rear of foam. Like the original this helps keep the hog rings from pulling through the foam. Used spray adhesive no. 77 to adhere.

GJS

Senior Member

I am usually suspect when the word "epic" is thrown around. .. but it's rather spot on for this thread. Good work, man.90 hours into it.

If the spring wire burlap was pre- made, I would probably have 45 hours or so into it. I will have to go back and look at my time notes.

Working on the finer details of the rear bench prepping it for covers. I will bore you with detail pictures.

Every thing is the way the originals were.

Added “silencing”inserts to the front of the rear frame. It is to help keep the kids from bottoming out on the big bumps. Jute insulation/ padding.

View attachment 229164 View attachment 229165

This is for the person riding the hump. The foam is your only suspension.

View attachment 229166

Edge protection for the foam. The rear bench only has foam there is no cotton batting on the rear bench. Jute insulation/ padding.

View attachment 229167

Adding light canvas hog ring support strips to rear of foam. Like the original this helps keep the hog rings from pulling through the foam. Used spray adhesive no. 77 to adhere.

View attachment 229168

Its a good thing your not on the clock, they'd be working out how to replace you with a machine by now...90 hours into it.

If the spring wire burlap was pre- made, I would probably have 45 hours or so into it. I will have to go back and look at my time notes.

Outstanding work, thank you for sharing this with us. Someday I'm going to try my hand at this... your experience has been very helpful.

90 hours into it.

If the spring wire burlap was pre- made, I would probably have 45 hours or so into it. I will have to go back and look at my time notes.

Working on the finer details of the rear bench prepping it for covers. I will bore you with detail pictures.

Every thing is the way the originals were.

Added “silencing”inserts to the front of the rear frame. It is to help keep the kids from bottoming out on the big bumps. Jute insulation/ padding.

View attachment 229164 View attachment 229165

This is for the person riding the hump. The foam is your only suspension.

View attachment 229166

Edge protection for the foam. The rear bench only has foam there is no cotton batting on the rear bench. Jute insulation/ padding.

View attachment 229167

Adding light canvas hog ring support strips to rear of foam. Like the original this helps keep the hog rings from pulling through the foam. Used spray adhesive no. 77 to adhere.

View attachment 229168

WOW! Ninety hours so far. . . At $50 per hour, yer already at $4500, and the covers ain't even on yet. But what you have learned and the fact that some "pro" doing the job would not do it correctly the way you did, its still worth doing the job yourself.

WOW! Ninety hours so far. . . At $50 per hour, yer already at $4500, and the covers ain't even on yet. But what you have learned and the fact that some "pro" doing the job would not do it correctly the way you did, its still worth doing the job yourself.

The fun part for me is the problem solving and figuring out how it was done or how it could have been done.

For $4500 I could have bought a sewing machine that would stitch up the cotton batting cushions and bought a real wire wire straightener and saved loads of time.

I over ordered the vinyl

For the smooth grain for the sides, front backs and middle section will take just over 4 yards with 48” wide material. I was pretty frugal laying it out, but don’t think I could get it under 4. If no mistakes 5 yards would do it. I have 8 to work with. For the course grain material which are the quilted inserts look to be just under 4 yards. If no mistakes I could almost make another set of covers as I ordered 8 yards of both. The course grain is 53” wide.

We will see what happens.

For the smooth grain for the sides, front backs and middle section will take just over 4 yards with 48” wide material. I was pretty frugal laying it out, but don’t think I could get it under 4. If no mistakes 5 yards would do it. I have 8 to work with. For the course grain material which are the quilted inserts look to be just under 4 yards. If no mistakes I could almost make another set of covers as I ordered 8 yards of both. The course grain is 53” wide.

We will see what happens.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 0

- Views

- 401

- Replies

- 14

- Views

- 10K