I'm admiring how faithfully you are reproducing the hidden stuff. I feel certain it will pay off when your finished with the seats. I have a notion to attempt something like this one day myself... I am getting an old machine Mom thinks will work for this in July.Thanks. The scary part is going to be when I have to start assembling my seat covers. The stuff I am working on now will be the foundation, but hidden.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Epic 68 Polara bench seat rebuild for originality

- Thread starter HWYCRZR

- Start date

A machine capable of stitching a hi loft material with out compressing it cut the time of this part by 75%. I wish I knew someone that owns a mattress factory. Any way done with that part and moving back to the burlap with wires stitched through them to keep the load even on the springs.

The burlap woven wire part has been a challenge. So far I have been too stubborn to use a different method. The easy way would be to tie the springs with listing wire to make them function as a system. The OEM was was to have a burlap piece stitched with spring wire. I am sure their suppliers had machines that would produce these in minutes.

I envision their machines to have 18-20 wire spools that would straighten the wire thread it through the burlap and tie the end in one or two simple steps.

In post #29. I talked about the issue of finding straight spring wire around 50-60” long.

I ordered wire and made a straightener. It works ok. Instead of tight coils I can at least get it straight enough that it only has a slight cast. I am hoping when I hog ring it to the seat it will be fine. I would have to add another plane of rollers to straighten it more.

Yeah I know it is probably time to clean off the bench.

I envision their machines to have 18-20 wire spools that would straighten the wire thread it through the burlap and tie the end in one or two simple steps.

In post #29. I talked about the issue of finding straight spring wire around 50-60” long.

I ordered wire and made a straightener. It works ok. Instead of tight coils I can at least get it straight enough that it only has a slight cast. I am hoping when I hog ring it to the seat it will be fine. I would have to add another plane of rollers to straighten it more.

Yeah I know it is probably time to clean off the bench.

Trying to tie the cord to the spring wire is kicking my but. It is very difficult to wrap spring wire around something. Needle nose pliers gets the loop started, but am struggling to continue the loop tight around the cord. I think I have about all the pliers And crimp tools I own out, but am struggling. What I need is a mini hog ring pliers or heavy duty jewelry crimper. I need something that will continue to wrap the wire as it is tightening. Regular hog ring pliers are too big.

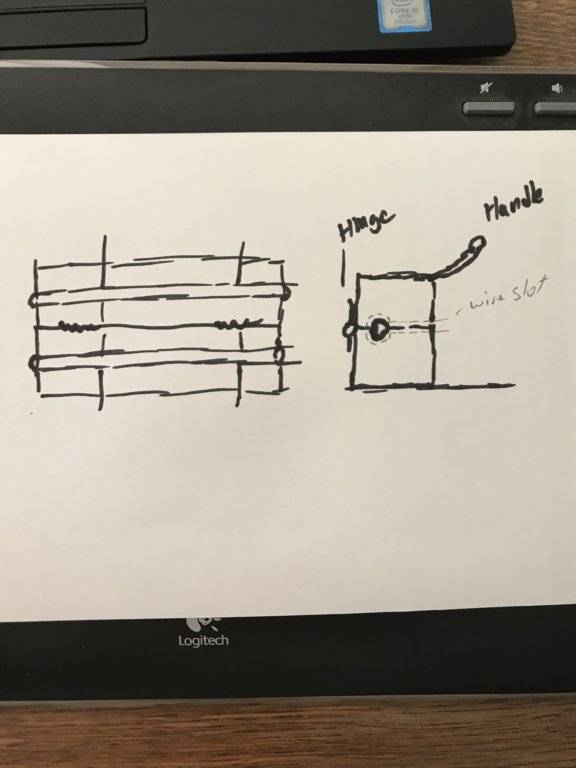

I think it is about time to face this again. I put it aside when I got my car home, but I was struggling with bending the spring wire around the cord. I woke up this morning with an idea for a bending jig. I think if I take two wood blocks, center drill, cut wire guides and hinge it I can get the bend around the cord and tighten. The block should be able to bend the wire around and keep it straight.

Ask @TerryM how he did his springs. If you haven't seen his restoration it is epic.

1965 pace car restoration

1965 pace car restoration

I saw his spring bending pretty impressive. My problem is the wrapping around the cord. I can’t do a simple pin jig as I have to work with the burlap and cord as a system. My problem is getting the spring wire started in a small bend.

1st step jig. Thread cord in groove, put wire in slots, bend it over. Success (I hope) this should help force the bend and keep it contained.

2nd. Maybe heat on the ends and wrap around a small hydraulic tube to get the eye started?

3rd. Find some small wire clips and clip it together. Of course the easy way would be to use covered listing wire and tie the springs. But I am still hung up on original intent. (But starting to get over it)

1st step jig. Thread cord in groove, put wire in slots, bend it over. Success (I hope) this should help force the bend and keep it contained.

2nd. Maybe heat on the ends and wrap around a small hydraulic tube to get the eye started?

3rd. Find some small wire clips and clip it together. Of course the easy way would be to use covered listing wire and tie the springs. But I am still hung up on original intent. (But starting to get over it)

65Fury440

Senior Member

Rate this thread and OP a 10.

Enjoying immensely.

Enjoying immensely.

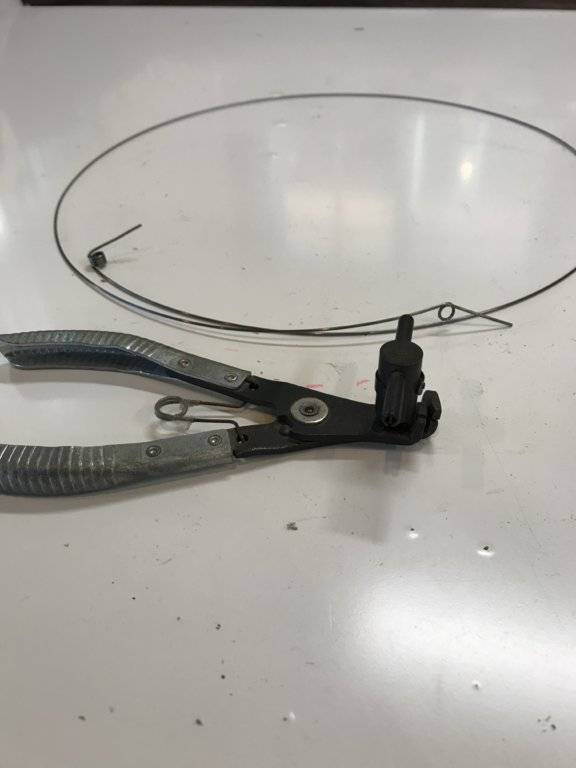

How about something like these? https://www.hemmings.com/blog/2016/05/25/from-the-toolbox-7/

I haven't seen any for a while and they're designed to put the curl on the end of a control cable but it will put a nice 3/16" loop on the end of a piece of spring wire........... I do have a pair if they'll help.

I haven't seen any for a while and they're designed to put the curl on the end of a control cable but it will put a nice 3/16" loop on the end of a piece of spring wire........... I do have a pair if they'll help.

How about something like these? https://www.hemmings.com/blog/2016/05/25/from-the-toolbox-7/

I haven't seen any for a while and they're designed to put the curl on the end of a control cable but it will put a nice 3/16" loop on the end of a piece of spring wire........... I do have a pair if they'll help.

Mike, I think I would like to give them a try. I think I could make the loop, thread the cord through and give it a cinch. My current loops with the hydraulic tube are a little big. I also have a few vent cables to re-coil. Are they for sale, or loan only?

Thank you

Marty

Loops, but pipe is about 3/8” diameter which means when the loop springs back it is about 1/2” dia. When I cinch down the cord it kinks a little. I have a little slot in the end of the tube. Stick the wire halfway through and start rolling.

65sporty

Old Man with a Hat

I have used these also, really pretty cool. The pair we had at the shop may have been lost when we had the fire in 2014Mike, I think I would like to give them a try. I think I could make the loop, thread the cord through and give it a cinch. My current loops with the hydraulic tube are a little big. I also have a few vent cables to re-coil. Are they for sale, or loan only?

Thank you

Marty

Loan only, may have to make more cables in the future. Not sure when I'll be down that way though, may have to shtick 'em in the mail.

Loan only, may have to make more cables in the future. Not sure when I'll be down that way though, may have to shtick 'em in the mail.[/QUOTE

I tried. I never pass up an opportunity to buy more tools. But then again I helped my dad clean out his storage unit a couple of years ago...... I think we could have re- stocked Harbor freight. I kept the more unique and interesting tools, but many were duplicates as to what I had already collected.

Thank you so much. My I owe you list is growing.

Thank you @Polara_500

I received the tool today. I think this will work great. Thanks again for the help you have offered.

A couple of test bends.

I received the tool today. I think this will work great. Thanks again for the help you have offered.

A couple of test bends.

It does make some purty little circles in wire.

Decided I didn’t like my first attempt without the eyelet pliers. Only 18 more wires @50” each to straighten.

I would run the wire back and forth through the straightener then put the eye on one end. About 3 hours time for 40 wires. Only 20 to go.

I would run the wire back and forth through the straightener then put the eye on one end. About 3 hours time for 40 wires. Only 20 to go.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 0

- Views

- 401

- Replies

- 14

- Views

- 10K