Took a break yesterday to adjust the newly welded kickstand mount on my ‘74 Suzuki TC125. Now I can disassemble again and blast and paint the frame. Also contemplated on popping the dent out of my gas tank.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hobby Upholstery shop setup and projects

- Thread starter HWYCRZR

- Start date

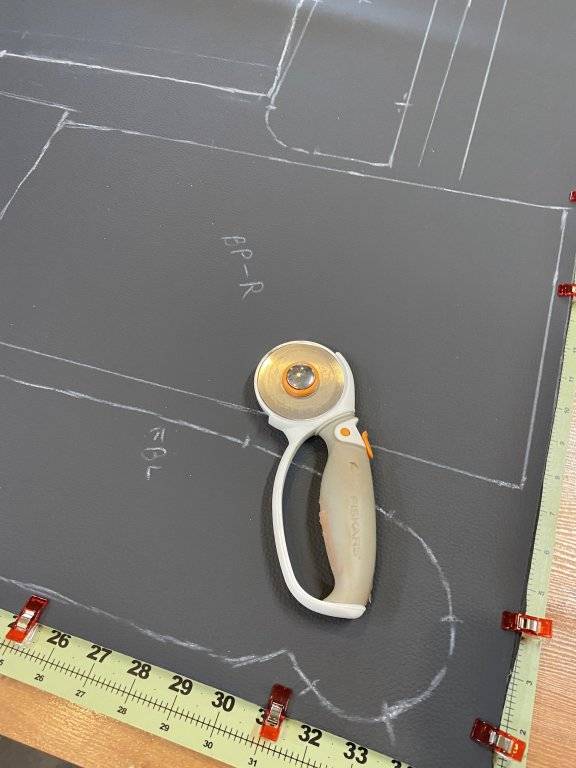

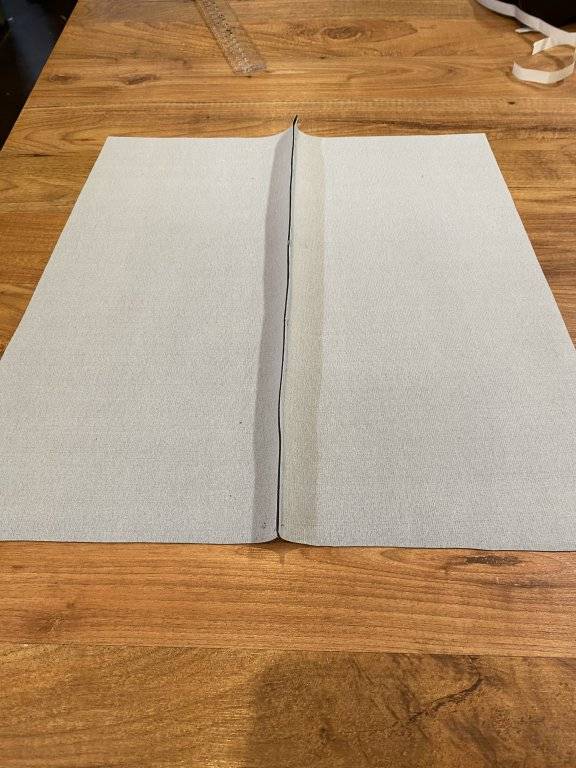

Made good progress this afternoon cutting out the new fabric for my barstools. After I traced the old covers and checked the mirror image (folded in half and flipped over), I did a little bit of re drawing. With stretched fabric as a pattern it is not always symmetrical from side to side. But if you trace one half and then flip it over and trace the other half it will at least be even on both sides.

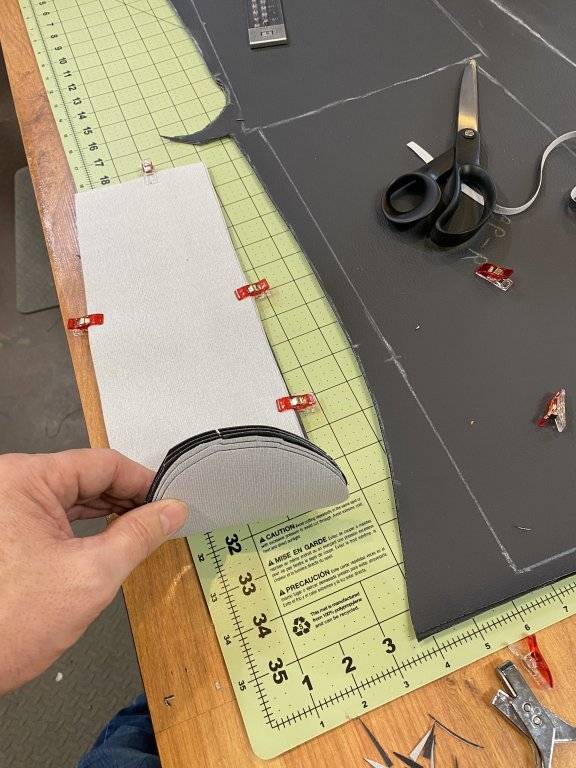

Checking the mirror image of left and right sides. Also above putting in alignment notches. Helps keep the edges aligned when sewing together.

Glad I had the new work surface. So nice to lay everything out flat.

Checking the mirror image of left and right sides. Also above putting in alignment notches. Helps keep the edges aligned when sewing together.

Glad I had the new work surface. So nice to lay everything out flat.

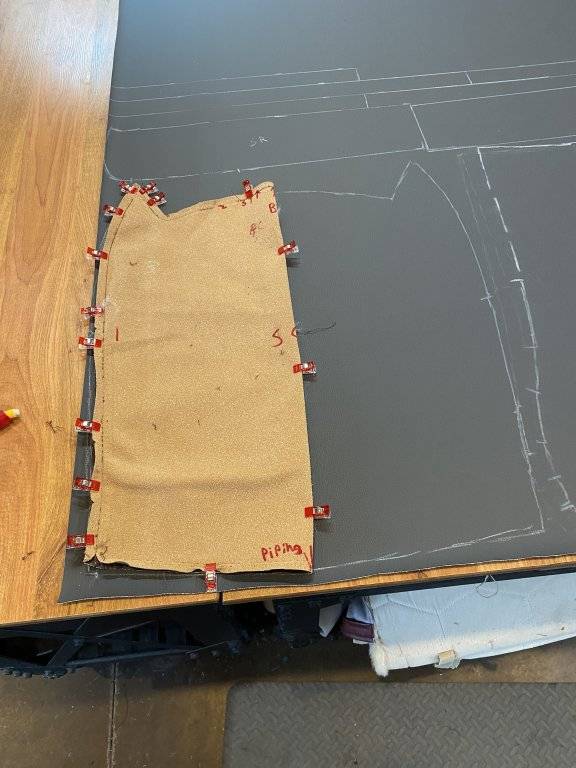

I got pieces for all 6 stools cut out and ready to start sewing together. But before I started sewing together, I decided to take one more apart to verify what pieces needed to be sewn first.

Man there are a lot staples. It took a little over an hour to remove all the staples and disassemble. Only four left to take apart.

Man there are a lot staples. It took a little over an hour to remove all the staples and disassemble. Only four left to take apart.

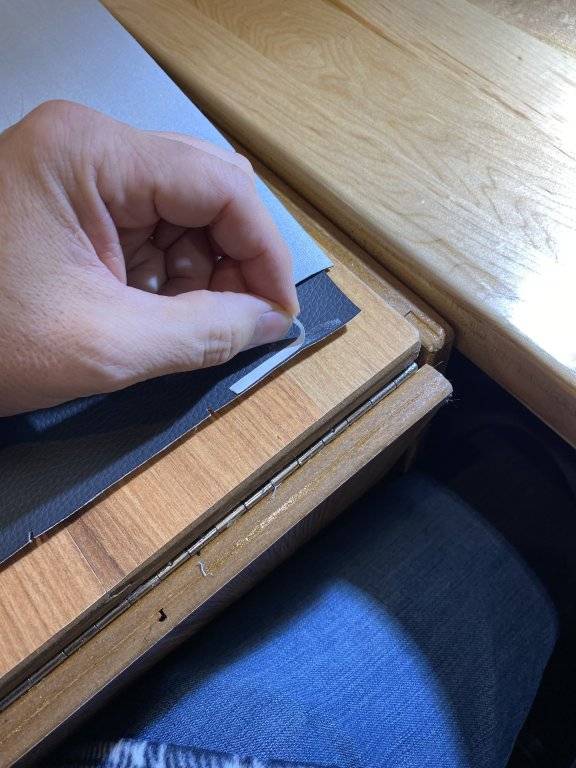

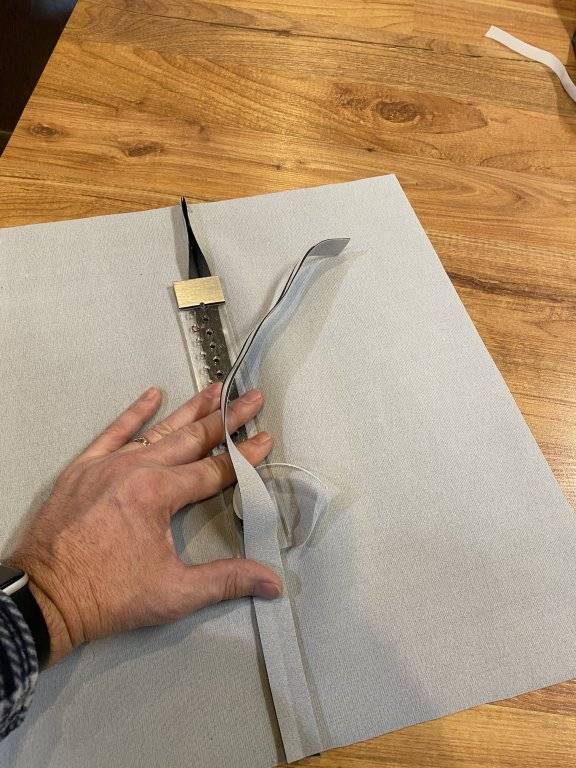

Here’s where the indexing notches come into play. If you think about your sewing machine and adding small panels going around corners to larger panels it is directional. Meaning you on one side of the panel you start at the bottom of the panel and see to the top, but on the opposite side you will need to turn it around and see from the top of the panel to the bottom. The indexing notches help make sure that you are aligned regardless of the direction you start. Also for slick surfaces I use a couple of pieces of 1/4” basting tape (double sided tape usually from 1/4” to 3/4”wide) to hold. The tape holds it in place and provides an extra hand.

Making progress. I hope to finish sewing up all 6 covers today.

I have 6 bottoms sewed, 6 back cover panels sewed and have 3 seat backs sewed up. Today plan is to finish the other 3 seat backs, add the decorative white stitching, sew the seat and backs together, add edge piping and stapling edges.

I have 6 bottoms sewed, 6 back cover panels sewed and have 3 seat backs sewed up. Today plan is to finish the other 3 seat backs, add the decorative white stitching, sew the seat and backs together, add edge piping and stapling edges.

Six covers ready to sew together. Completed the decorative French seam on the back cover a the edge seams on the seat and seat back. The contrasting color really makes them pop, but really have to pay attention to detail as screw ups are hard to hide. Two things you need that will save you a lot of time. An edging foot which has a little guide that will help you follow the seam and a cording foot which straddles the piping for a guide and a nice tight seam. I need to make the cording next and then see everything together. Will see if I get at least one recovered today.

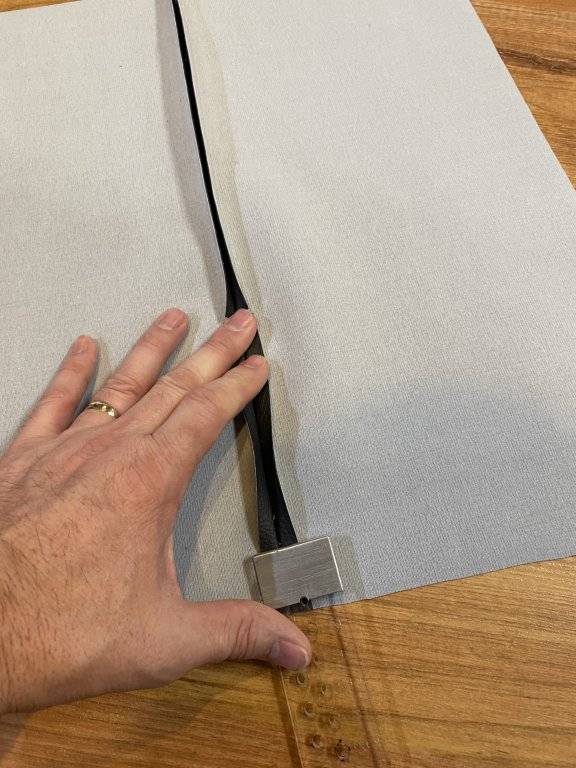

First three pictures , flattening the seam for the French seam (dual seam). Used the basting tape and an extra strip to hold the seam flat and also add strength to the seam.

French seam. Old vs new.

making sure it matches my chair and couch style. Not quite as shiny but tone and style close enough.

Test fit.

All 6 panels

Edging foot

First three pictures , flattening the seam for the French seam (dual seam). Used the basting tape and an extra strip to hold the seam flat and also add strength to the seam.

French seam. Old vs new.

making sure it matches my chair and couch style. Not quite as shiny but tone and style close enough.

Test fit.

All 6 panels

Edging foot

3175375

Old Man with a Hat

Very nice! Great job and a useful hobby!Sewed one completely together and tried it out. I think it went pretty good.

Five more to assemble and staple together.

View attachment 634093View attachment 634094View attachment 634095View attachment 634096View attachment 634097

I was wondering if you were restoring that old Suzuki . You could supplement your hobbey with bike seats . Here is a Maico 490 I restored

Took a break yesterday to adjust the newly welded kickstand mount on my ‘74 Suzuki TC125. Now I can disassemble again and blast and paint the frame. Also contemplated on popping the dent out of my gas tank.

View attachment 633728View attachment 633729

Looks great.I was wondering if you were restoring that old Suzuki . You could supplement your hobbey with bike seats . Here is a Maico 490 I restored

View attachment 634318View attachment 634319View attachment 634320

Yes I am restoring it. I bought it off a buddy when I was in high school in ‘84. I rode it to hell and back across the fields and hilly Montana pastures. Then it sat in the shop at the farm from ‘88 until 2019. Ironically I found seat covers online for cheap, with the silk screen logo. I suppose for non mainstream bikes I could do some covers, just wouldn’t be able to silkscreen.

I now have the final five covers completed and ready for installation. I still have to remove the old covers from four stools. So about another 4 hours worth.

Some key things I learned in sewing the covers together.

The first cover was a good idea to fully complete and install. That way if I found any anomalies I could correct for the others.

The first cover also took the longest to clip together as you are not quite sure of how it will feed through the sewing machine evenly. Second cover was a little quicker, and by the third I learned to use some basting tape on the trouble spots (corner turns) which made clamping and alignment easier. The fourth through sixth went pretty quickly.

Some key things I learned in sewing the covers together.

The first cover was a good idea to fully complete and install. That way if I found any anomalies I could correct for the others.

The first cover also took the longest to clip together as you are not quite sure of how it will feed through the sewing machine evenly. Second cover was a little quicker, and by the third I learned to use some basting tape on the trouble spots (corner turns) which made clamping and alignment easier. The fourth through sixth went pretty quickly.

I have a total of three complete. Last one took 2-1/2 hours to pull off the old cover and re-install the new. It is getting quicker on the installation, but removing the old staples is about the same time. Even if I can cut the change time down to two hours, I still have six hours remaining to finish.

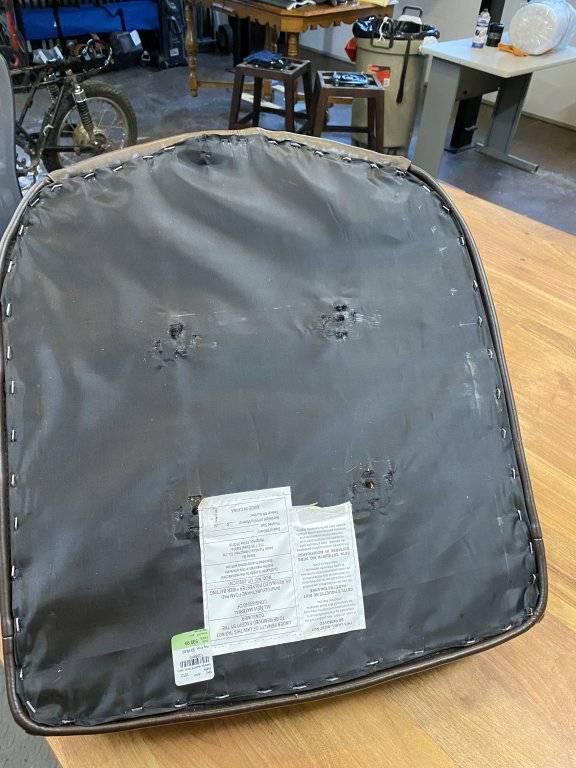

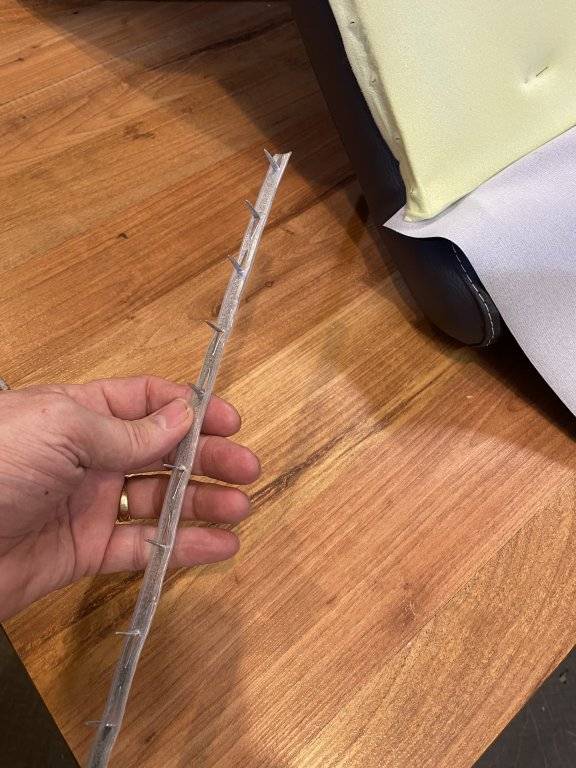

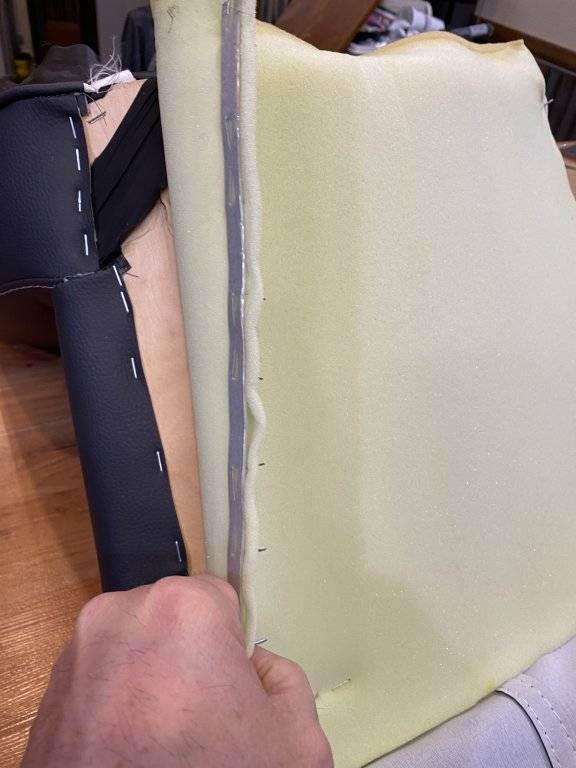

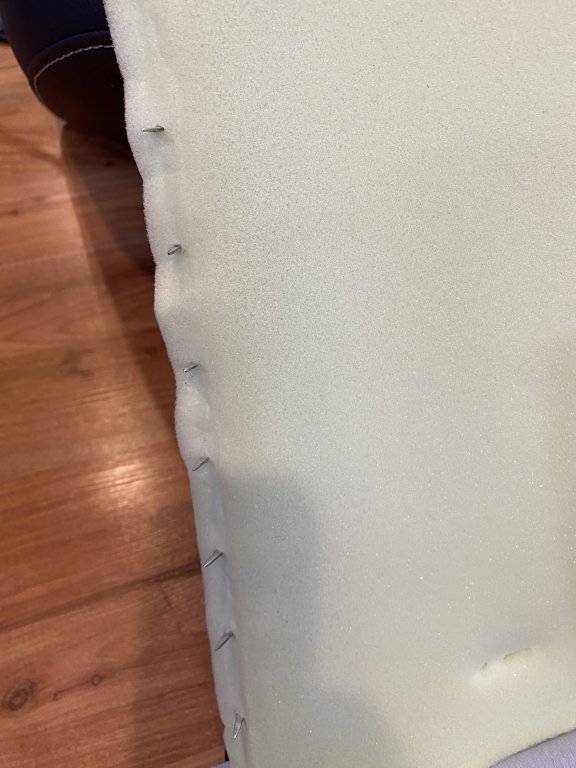

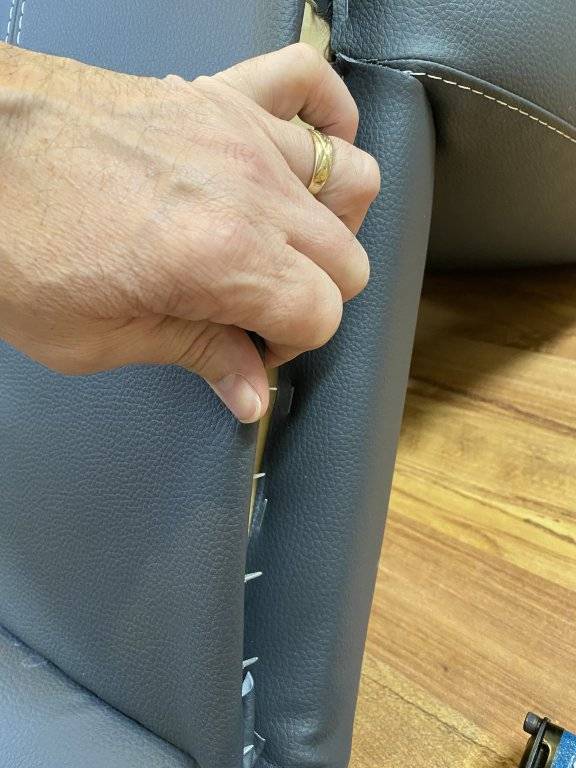

Another thing of note that works pretty slick are the tack strips to finish the back panel. They go through a foam piece and then the back panel piece. Then you flip it upside down stretching the fabric and use a small tack hammer to hammer in place. I used a piece of old fabric to keep the hammer from marring the new fabric. Keeps the edge nice and straight.

On stool number four I decided to time myself from start to finish including taking the legs off and putting them back on.

Disassembly took 1:13.

Putting the cushion wrap another :18 minutes.

Installing the seat cover. 1:14

I did start putting the back panel on upside down so had to remove a few staples and re due.

Total time right about 2:45.

Disassembly took 1:13.

Putting the cushion wrap another :18 minutes.

Installing the seat cover. 1:14

I did start putting the back panel on upside down so had to remove a few staples and re due.

Total time right about 2:45.

twostick

Senior Member

No tuck and roll??? LolOn stool number four I decided to time myself from start to finish including taking the legs off and putting them back on.

View attachment 634839View attachment 634840View attachment 634841

Disassembly took 1:13.

View attachment 634842

Putting the cushion wrap another :18 minutes.

View attachment 634843

Installing the seat cover. 1:14

View attachment 634844

I did start putting the back panel on upside down so had to remove a few staples and re due.

Total time right about 2:45.

Looks good. Just like you know what you are doing.

Kevin

My fingers feel like they have been tucking and rolling. You don’t realize how much you use your fingers to remove the staples and to hold the fabric to staple it. I am learning with every project. And on every stool. Stool 5 took 2:28. So cut about 15 minutes off. Eventually I guy should learn what direction to move the fabric to keep the bunching down and keep it smooth and straight.No tuck and roll??? Lol

Looks good. Just like you know what you are doing.

Kevin

Finally finished the last one. 2:14 for the full turn around from stripping off the old and putting on the new covers. Overall I am very happy with the results.

For the six stools I have about 30 hours from tracing the patterns, to stitching up the covers and installing them.

Next time maybe I could cut 5 or so hours off due to experience. Maybe a little more?

Now the economic part.

If my time was only worth $30 per hour I would have to charge $750 for the labor to do six stools. The synthetic leather was awesome material to work with but about $48 per yard. I used a little over 6 yds so rounding it to 7 yds would be $336. Then you have the little supplies of cording, staples and thread. I didn’t use $30 of thread, but had to buy it for the project. About $6 for the cording and call it $5 for the staples.

Total time and materials $1,122 for 6 stools =$187 each to recover.

Originally I only paid $100 each, but they didn’t quite last 10 years. But to replace them with this quality of material (if I could find the color and style) I would probably be at $200 each to replace anyway.

Since I was on vacation getting paid, my time was free. So with some sweat equity. I am in about $387 total. So am into my new stools for about $65 each.

I think I did okay.

For the six stools I have about 30 hours from tracing the patterns, to stitching up the covers and installing them.

Next time maybe I could cut 5 or so hours off due to experience. Maybe a little more?

Now the economic part.

If my time was only worth $30 per hour I would have to charge $750 for the labor to do six stools. The synthetic leather was awesome material to work with but about $48 per yard. I used a little over 6 yds so rounding it to 7 yds would be $336. Then you have the little supplies of cording, staples and thread. I didn’t use $30 of thread, but had to buy it for the project. About $6 for the cording and call it $5 for the staples.

Total time and materials $1,122 for 6 stools =$187 each to recover.

Originally I only paid $100 each, but they didn’t quite last 10 years. But to replace them with this quality of material (if I could find the color and style) I would probably be at $200 each to replace anyway.

Since I was on vacation getting paid, my time was free. So with some sweat equity. I am in about $387 total. So am into my new stools for about $65 each.

I think I did okay.

Last edited:

Similar threads

- Replies

- 20

- Views

- 1K

- Replies

- 9

- Views

- 960