I now have row after row of metric sockets and wrenches I used to us for those occurrences. Now occasionally used.I need the teenie-weenie hands adapter, it would be very helpful when working on my Toyota.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Meet Buttercup, a 1972 New Yorker Brougham 2-door Hardtop

- Thread starter ayilar

- Start date

marty koirtyohann

Well-Known Member

thre is something u can put in the cooling system after u get it flushed out (if u plan to do thar )its call water glass its what chrysler use to use on the green 318 locks@ the dealer ship if they got a rusty block i think thy used a acid to eat the rust out then to seal it so it does not rust any more they put in the water glass i dont remember what the active ingredient was but it would stiop the "freeze/casting "plugs from rusting out just though u msay lik to knowHow is it that some of the freeze plugs can look so bad and yet you indicate the coolant passages were in "excellent condition". Whenever I have removed such freeze plugs the passages are filled with plenty of sediment? This is an interesting finding.....................

marty koirtyohann

Well-Known Member

u r welcomedthre is something u can put in the cooling system after u get it flushed out (if u plan to do thar )its call water glass its what chrysler use to use on the green 318 locks@ the dealer ship if they got a rusty block i think thy used a acid to eat the rust out then to seal it so it does not rust any more they put in the water glass i dont remember what the active ingredient was but it would stiop the "freeze/casting "plugs from rusting out just though u msay lik to know

73Coupe

Senior Member

thre is something u can put in the cooling system after u get it flushed out (if u plan to do thar )its call water glass its what chrysler use to use on the green 318 locks@ the dealer ship if they got a rusty block i think thy used a acid to eat the rust out then to seal it so it does not rust any more they put in the water glass i dont remember what the active ingredient was but it would stiop the "freeze/casting "plugs from rusting out just though u msay lik to know

How to Use a Liquid Glass Cooling System Sealer

fury fan

Old Man with a Hat

I am not a chemist but I sometimes know something about something.

Sodium silicate is what was used to seize the engines in the cash-for-clunkers program.

From that article:

Cooling system sealers such as liquid glass can often temporarily stop a leak until repaired properly. Liquid glass refers to sodium silicate, which creates a glass-like coating internal to the cooling system to repair leaks.

Note the words glass-like and temporary.

Requirements of such a sealer:

If it is to provide a coating on the metallic surfaces, it must adhere to 'dirty' surfaces of cast iron, aluminum, steel/brass (core plugs), and copper/brass (radiators and heater cores).

If a coating, it must adhere under all the varying coefficients of expansion of all the metals (and coatings) in the system.

It cannot dislodge anywhere, lest it risk causing a clog, nor even simply permit coolant to wick between it and the metal surface (which defeats the whole purpose).

It must not be affected by, or have an adverse reaction with, any of the various materials used for sealing (head gaskets, paper T-stat gasket, water pump seal hoses, solders, etc) nor the coolant chemistry.

It cannot adversely modify the heat-transfer characteristics of the crucial areas (tops of cylinders, cylinder heads, radiator and heater core.

It apparently professes to be effective in spite of the wide range of materials in modern cars vs classic cars.

And probably some other stuff, too.

I am therefore a bit skeptical for how well such a product would work across-the-board.

Ignoring teh potential for new freeze plugs to be made out of crap metal that corrodes easily, I would say for most of us that R&R of plugs and coolant will be a sufficiently long-lasting repair.

Sodium silicate is what was used to seize the engines in the cash-for-clunkers program.

From that article:

Cooling system sealers such as liquid glass can often temporarily stop a leak until repaired properly. Liquid glass refers to sodium silicate, which creates a glass-like coating internal to the cooling system to repair leaks.

Note the words glass-like and temporary.

Requirements of such a sealer:

If it is to provide a coating on the metallic surfaces, it must adhere to 'dirty' surfaces of cast iron, aluminum, steel/brass (core plugs), and copper/brass (radiators and heater cores).

If a coating, it must adhere under all the varying coefficients of expansion of all the metals (and coatings) in the system.

It cannot dislodge anywhere, lest it risk causing a clog, nor even simply permit coolant to wick between it and the metal surface (which defeats the whole purpose).

It must not be affected by, or have an adverse reaction with, any of the various materials used for sealing (head gaskets, paper T-stat gasket, water pump seal hoses, solders, etc) nor the coolant chemistry.

It cannot adversely modify the heat-transfer characteristics of the crucial areas (tops of cylinders, cylinder heads, radiator and heater core.

It apparently professes to be effective in spite of the wide range of materials in modern cars vs classic cars.

And probably some other stuff, too.

I am therefore a bit skeptical for how well such a product would work across-the-board.

Ignoring teh potential for new freeze plugs to be made out of crap metal that corrodes easily, I would say for most of us that R&R of plugs and coolant will be a sufficiently long-lasting repair.

At Rip’s proposed price, no worries

Last edited:

marty koirtyohann

Well-Known Member

yes if u fill the cooling system completely with it . but its a small additive u mix e\with the antifreeze i hve used i alont on 138 ,400&440 that had a rust problem it stoped the rusting issue i have degrees in chemistry many yrs agoI am not a chemist but I sometimes know something about something.

Sodium silicate is what was used to seize the engines in the cash-for-clunkers program.

From that article:

Cooling system sealers such as liquid glass can often temporarily stop a leak until repaired properly. Liquid glass refers to sodium silicate, which creates a glass-like coating internal to the cooling system to repair leaks.

Note the words glass-like and temporary.

Requirements of such a sealer:

If it is to provide a coating on the metallic surfaces, it must adhere to 'dirty' surfaces of cast iron, aluminum, steel/brass (core plugs), and copper/brass (radiators and heater cores).

If a coating, it must adhere under all the varying coefficients of expansion of all the metals (and coatings) in the system.

It cannot dislodge anywhere, lest it risk causing a clog, nor even simply permit coolant to wick between it and the metal surface (which defeats the whole purpose).

It must not be affected by, or have an adverse reaction with, any of the various materials used for sealing (head gaskets, paper T-stat gasket, water pump seal hoses, solders, etc) nor the coolant chemistry.

It cannot adversely modify the heat-transfer characteristics of the crucial areas (tops of cylinders, cylinder heads, radiator and heater core.

It apparently professes to be effective in spite of the wide range of materials in modern cars vs classic cars.

And probably some other stuff, too.

I am therefore a bit skeptical for how well such a product would work across-the-board.

Ignoring teh potential for new freeze plugs to be made out of crap metal that corrodes easily, I would say for most of us that R&R of plugs and coolant will be a sufficiently long-lasting repair.

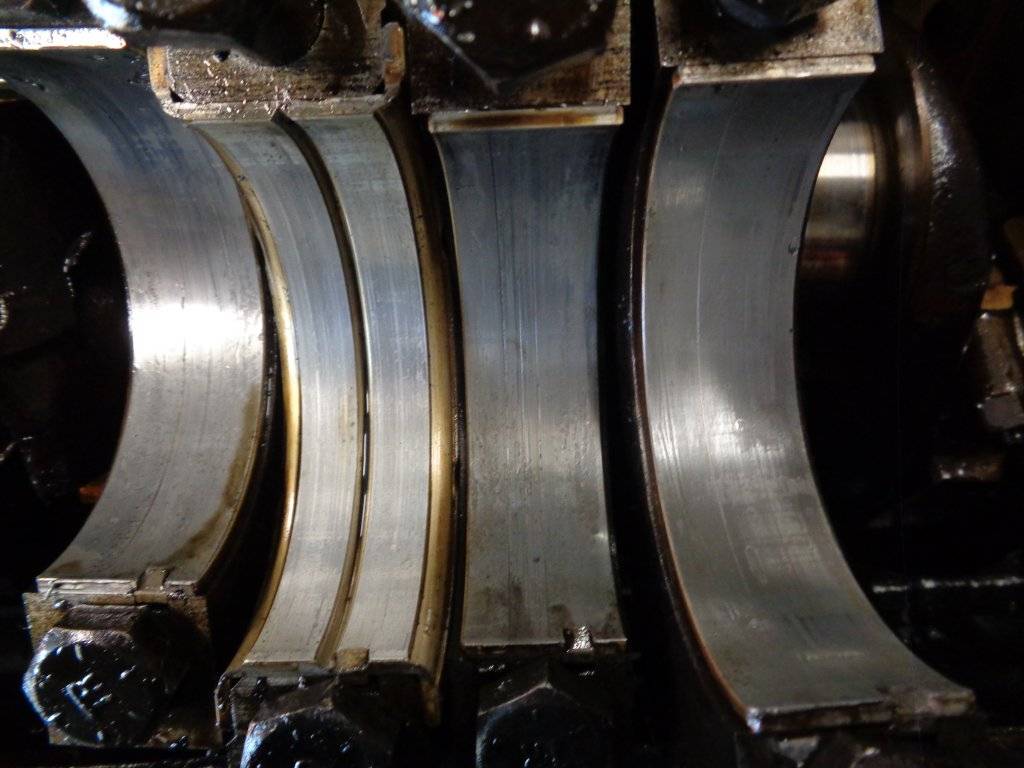

As previously posted in post #350 I had replaced two block freeze plugs. Michel and I had discussed in June before @sixpkrt 7th Annual C Body Show the necessity to replace the remaining freeze plugs at a later date. Other repairs would include a wheel alignment and correct the growing power steering leak. The power steering pump reservoir seal was the main culprit, the pump shaft seal was also changed as they were OEM original to the car and rock hard upon inspection. I had noticed an occasional oil light flicker on left hand turns. An oil pressure test was performed, and the results were not good. On cold start the press. was 45 psi at idle. fully warmed up after 20 minutes of highway driving revealed a idle pressure of 10-15 psi. Since I would have the engine out for freeze plug replacement, now would be a good time to pull the oil pan and check for a partially plugged oil pickup screen, debris in the oil pan. removal of the oil pan gave me quite a surprise, a heavy buildup of bearing material was found.

With that find I removed the main bearing caps to check bearing wear. To my surprise the main bearings although scratched and contaminated were in better shape than expected. The main bearing journals were in much better condition than expected. Crankshaft removal and measuring set for tomorrow.

Pull all connecting rod caps and the rod bearings were very worn. several fell out of the rod caps. Since I could see the timing chains condition, I removed the water pump housing and the timing cover. The chain and gears were definitely OEM. Check the chain wear. Stay tuned more tomorrow.

A perfect opportunity to build a (mild) stroker!

I can picture @ayilar grinning whilst driving that thing, just DARING a Fairlane or a Caprice to give him a try!

I can picture @ayilar grinning whilst driving that thing, just DARING a Fairlane or a Caprice to give him a try!

The problem when adding power, is that one then has to get the brakes to match. Pretty soon, one might as well have bought a C8 or a Demon. Oh, wait, is that where you are leading me?A perfect opportunity to build a (mild) stroker!

I can picture @ayilar grinning whilst driving that thing, just DARING a Fairlane or a Caprice to give him a try!

As previously posted in post #350 I had replaced two block freeze plugs. Michel and I had discussed in June before @sixpkrt 7th Annual C Body Show the necessity to replace the remaining freeze plugs at a later date. Other repairs would include a wheel alignment and correct the growing power steering leak. The power steering pump reservoir seal was the main culprit, the pump shaft seal was also changed as they were OEM original to the car and rock hard upon inspection. I had noticed an occasional oil light flicker on left hand turns. An oil pressure test was performed, and the results were not good. On cold start the press. was 45 psi at idle. fully warmed up after 20 minutes of highway driving revealed a idle pressure of 10-15 psi. Since I would have the engine out for freeze plug replacement, now would be a good time to pull the oil pan and check for a partially plugged oil pickup screen, debris in the oil pan. removal of the oil pan gave me quite a surprise, a heavy buildup of bearing material was found.

View attachment 626916

View attachment 626917

View attachment 626918

Aaarrrggghhh!

71Polara383

Kid with ballcap

The disc's in our cars do just fine. If we were talking 700+ wheel horsepower that'd be a whole different situation.The problem when adding power, is that one then has to get the brakes to match. Pretty soon, one might as well have bought a C8 or a Demon. Oh, wait, is that where you are leading me?

71Polara383

Kid with ballcap

I never anticipated this from my experience with Buttercup. Dang!!!

Yes, the discs in our cars do just fine at ordinary speeds. But when Buttercup is barreling along I-65 or I-70 at a buck-40, coming down a ramp for a gas stop could be an issue!The disc's in our cars do just fine. If we were talking 700+ wheel horsepower that'd be a whole different situation.

71Polara383

Kid with ballcap

The Police cars didn't seem to have much of an issue.Yes, the discs in our cars do just fine at ordinary speeds. But when Buttercup is barreling along I-65 or I-70 at a buck-40, coming down a ramp for a gas stop could be an issue!

Now if it had to be done over and over and over. I could see fade becoming a concern.

Samplingman

Old Man with a Hat

Hmmm, here’s an idea….keep it stock!

73Coupe

Senior Member

Y'all are in too deep with that engine to pull out now....

Let the fun begin!

Let the fun begin!

fury fan

Old Man with a Hat

That's the nicest nylon timing gear I've ever seen.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 33

- Views

- 4K

- Replies

- 12

- Views

- 1K