For those interested. 1970 Fury save. I hope.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mopar Connection bought a 70 Fury Rag.

- Thread starter Boydsdodge

- Start date

I skimmed through part 2 on this...

I see he's using the junk repop quarters and saying they're "good", so that makes me question a lot. Worthy of note, he has ACC carpet for the car. I seem to remember that they weren't offering the 'vert version of this carpet.

I see he's using the junk repop quarters and saying they're "good", so that makes me question a lot. Worthy of note, he has ACC carpet for the car. I seem to remember that they weren't offering the 'vert version of this carpet.

Rustymuscle

New Member

Hey Big_John! By "good" I mean "good condition" – are the great or high quality? Nope. But they'll work for the small patchwork I need to do.

And yes! ACC did provide us a carpet kit. No, they do not list one for a convertible and almost talked me out of it, but I assured them I was going to be using their kit either way, so they sent out some extra pieces and asked that I take some added measurements that they might be able to use for a convertible kit in the future.

Once I patch up the floors where I can and POR15 the whole dang thing, I'll begin laying out the carpet and providing them those measurements.

And yes! ACC did provide us a carpet kit. No, they do not list one for a convertible and almost talked me out of it, but I assured them I was going to be using their kit either way, so they sent out some extra pieces and asked that I take some added measurements that they might be able to use for a convertible kit in the future.

Once I patch up the floors where I can and POR15 the whole dang thing, I'll begin laying out the carpet and providing them those measurements.

Last edited:

Anytime someone saves a '70 Fury vert I'm all in! Good luck and I can't wait to see more videos of the process.

Hey Big_John! By "good" I mean "good condition" – are the great or high quality? Nope. But they'll work for the small patchwork I need to do.

And yes! ACC did provide us a carpet kit. No, they do not list one for a convertible and almost talked me out of it, but I assured them I was going to be using their kit either way, so they sent out some extra pieces and asked that I take some added measurements that they might be able to use for a convertible kit in the future.

Once I patch up the floors where I can and POR15 the whole dang thing, I'll begin laying out the carpet and providing them those measurements.

ACC bought Trim Parts a few years ago. Trim Parts was a pretty good supplier of molded carpet and they offered the convertible carpet and it fit well. I have one in my '70 300 convertible. There's been a few conversations on here about it. The big thing was they (ACC) doesn't make the rear section long enough to go under the convertible rear seat. There may be some differences on the seat belt locations too, but I'm not sure on that one. Point being, Trim Parts made the carpet and now ACC should have patterns and tooling from Trim Parts.

Regarding the aftermarket panels... Here's the big problem I have... The quality of that repop is mediocre at best. I've seen these pieces, held it in my hands and even tried to use some of it once. It's junk and the guys selling it are misrepresenting it as good replacements.

We have lots of guys sign on here with their c-body project cars and the first thing they find out is there is no good replacement sheet metal. AMD and Goodmark know that it's a small market and they aren't going to tool up for any C body stuff. So a google search comes up with these repops. They spend their hard earned money only to find out that they are too thin, don't have the proper contours and are going to be a lot more work to fit. So now you have $800+ on some junk that a good body shop won't touch and if they do get fitted to the car, it's usually easy to spot the wrong curves and how they are attached and finished.

Now you come along and say "these are good" and endorse this garbage. In this venue, you explain that they aren't "great or high quality", but chances are a lot more people are going to watch the video than read about it here. Maybe you can even make some patches work, but the guy that needs more is going to buy these patches based on your video and be extremely disappointed. The only winner is the guy that sold you the panels. Most times you can't give these away...

IMHO, the hobby is having some upheavals with a lot of the cars pricing themselves out of contention for the average guy looking for a car to have some fun with and go to Cars and Coffee at the local Dairy Queen every Saturday morning. We have the end of the baby boomers and the beginnings of Gen X getting involved (as they retire) and some are finding that the C bodies are an affordable alternative to the muscle cars that they can't really afford. They are also finding that it's easier to get parts for that expensive muscle car and there are no catalogs full of C body parts.

As you probably know, YouTube has become a great source of info for a lot of these guys, some of which that never really turned wrenches on these cars when they were new... and of course, the YouTube guys are making a little money from it all. Problem is that some don't know how to separate the truth from fiction, good advise from bad etc. People believe what they see and hear on the internet. We owe it to ourselves to try to keep the info out there honest and helpful and not lead anyone struggling with their project car down the wrong path. Of course, maybe telling the complete story doesn't lend itself to "views" and "likes".

So, what I'm asking is to tell the whole story... Tell them ACC doesn't really have the carpet... Tell them the panels are only good for small patches (I'll even disagree on that LOL). I think that would be more interesting to watch you go through the same issues we all face.

And just to show I'm not all criticism... Use an old soldering iron to make any holes in the new carpet. About a million times easier with a nice clean hole that doesn't try to unravel the carpet threads.I'll begin laying out the carpet

Rustymuscle

New Member

The soldering iron trick is an oldie-but-a-goodie, and what I used in our carpet kit installation video for my Charger.

I'll keep your suggestions in mind, as they're fair and honest, and particularly helpful to the uninitiated.

OK, I've got a question that doesn't belong here, but you've got a convertible and I'm stumped:

The bench seat I pulled out of the Fury had been reupholstered but the brackets had been super booger-welded with new "feet" and they had drilled new holes into the floor for them.

These were rotted to death, so I fished out a pair of '67 GTX bench seat brackets, cleaned 'em up and bolted them to the bench. Alas, the studs don't line up. Center-to-center, the new B-body brackets are 45-inches apart. The factory holes in the floor are 48-inches apart.

A quick glance at the rotted brackets show the track favoring the outside (B-body's have the track on the inside) and the studs placed further out than the B-body's. It's pretty obvious to me that I need C-body bench seat brackets.

So 1. am I right? And 2. anybody got a clean set they'd like to sell me?

I'll keep your suggestions in mind, as they're fair and honest, and particularly helpful to the uninitiated.

OK, I've got a question that doesn't belong here, but you've got a convertible and I'm stumped:

The bench seat I pulled out of the Fury had been reupholstered but the brackets had been super booger-welded with new "feet" and they had drilled new holes into the floor for them.

These were rotted to death, so I fished out a pair of '67 GTX bench seat brackets, cleaned 'em up and bolted them to the bench. Alas, the studs don't line up. Center-to-center, the new B-body brackets are 45-inches apart. The factory holes in the floor are 48-inches apart.

A quick glance at the rotted brackets show the track favoring the outside (B-body's have the track on the inside) and the studs placed further out than the B-body's. It's pretty obvious to me that I need C-body bench seat brackets.

So 1. am I right? And 2. anybody got a clean set they'd like to sell me?

Rustymuscle

New Member

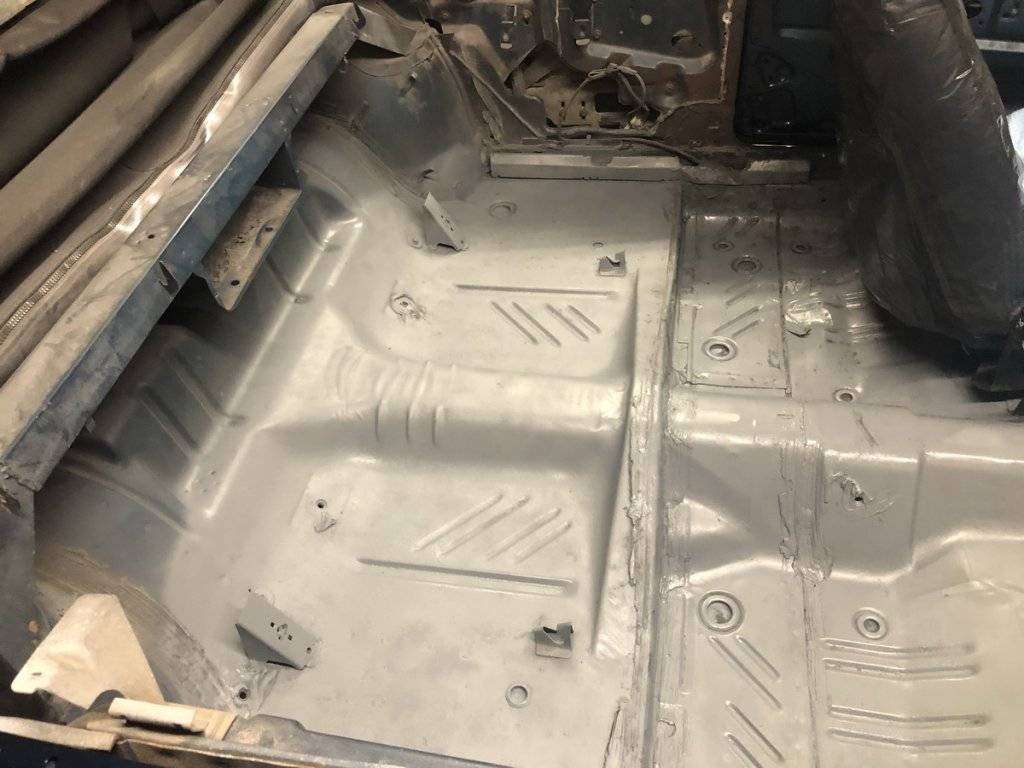

Oh yeah, and here's the latest update:

I'm not sure if this helps or not but here's a couple of pics of rear floors. The first one is mine and the second is from @bluefury361 's 69 300 vert.The soldering iron trick is an oldie-but-a-goodie, and what I used in our carpet kit installation video for my Charger.

I'll keep your suggestions in mind, as they're fair and honest, and particularly helpful to the uninitiated.

OK, I've got a question that doesn't belong here, but you've got a convertible and I'm stumped:

The bench seat I pulled out of the Fury had been reupholstered but the brackets had been super booger-welded with new "feet" and they had drilled new holes into the floor for them.

These were rotted to death, so I fished out a pair of '67 GTX bench seat brackets, cleaned 'em up and bolted them to the bench. Alas, the studs don't line up. Center-to-center, the new B-body brackets are 45-inches apart. The factory holes in the floor are 48-inches apart.

A quick glance at the rotted brackets show the track favoring the outside (B-body's have the track on the inside) and the studs placed further out than the B-body's. It's pretty obvious to me that I need C-body bench seat brackets.

So 1. am I right? And 2. anybody got a clean set they'd like to sell me?

There are 4 mounting brackets welded to the floor plus the brackets for the seat back. The outer 2 aren't quite as visible (I wasn't taking pics of them) in mine, and only marginally better in Will's car.

I don't know if the convertible seat mounts are different. The seats are.

My car isn't home right now... Stored up in my son's garage until they are done putting the new roof on my house. If need be I can easily pull the rear seat and snap some pics when they are done and my cars are back home.

I'm wondering if @MrMoparCHP might have some rear seat pics he could share.

Oh yeah, and here's the latest update:

Watched most of it. Real men don't use a mini starter.

How about this hint! Get a pool noodle at your local Walmart. Cut about 6" off it and slice it lengthwise. Put that over your hood latch to save your scalp. When not using it, I toss mine down in the well in front of the radiator. I've used tennis balls too, but the pool noodle is better.

@Rustymuscle -- thank you for posting about PM27G0D159805

I have taken the liberty to take a screenshot of the fender tag at 4:15-4:17 in your first video and will post it to the "Last Convertibles" thread.

I have taken the liberty to take a screenshot of the fender tag at 4:15-4:17 in your first video and will post it to the "Last Convertibles" thread.

Last edited:

Rustymuscle

New Member

LOL smart men don't stick with stock starters, Big_John.  Those things are trash.

Those things are trash.

I'm so used to my fiberglass hood on the Charger that I forgot about the skull cracker. It won't happen again (famous last words).

And no, I'm talking about the FRONT bench brackets, not the rear. The rear brackets are in good shape.

I'm so used to my fiberglass hood on the Charger that I forgot about the skull cracker. It won't happen again (famous last words).

And no, I'm talking about the FRONT bench brackets, not the rear. The rear brackets are in good shape.

cbarge

World Famous Barge in a Budget

B body seat brackets will not work in a C.

The time spent making the repop panels fit is the same amount if you fabricated your own from scratch.

Those panels look better patching up walls of an old barn.

The time spent making the repop panels fit is the same amount if you fabricated your own from scratch.

Those panels look better patching up walls of an old barn.

Rustymuscle

New Member

Yes, I've learned that about the brackets. Got a pair of C-body brackets you'd like to sell?

I have some from a right bucket seat, but not sure they are the same.

Rustymuscle

New Member

That's very much appreciated, but I think I'll play it safe and keep looking around. Thank you, sir!

MrMoparCHP

Old Man with a Hat

Here are some pictures of the back seat floor area, not sure what you are trying to see.

Alan

Alan

Rustymuscle

New Member

Thank you Alan, but I'm looking for FRONT BENCH SEAT BRACKETS. That's it. Sorry for the misunderstanding.

MrMoparCHP

Old Man with a Hat

The floor itself just had holes, the reinforcement was under the pan, they are there even on bucket seat cars.

Here are some pictures of the brackets. I had a some spares from a parts car but were cleared out long ago.

Alan

Here are some pictures of the brackets. I had a some spares from a parts car but were cleared out long ago.

Alan

live4theking

Old Man with a Hat

- Joined

- Nov 24, 2014

- Messages

- 12,884

- Reaction score

- 9,078

I cannot believe that no one has said Murray Park in Tiffin OH. Murray B. Park - Used and NOS Parts for Chrysler, Imperial, Dodge, Desoto, and Plymouth

Similar threads

- Replies

- 7

- Views

- 566

- Replies

- 4

- Views

- 514