I think this spring difference is a "thing" - that there is something to it.

Doing some searching I came across this thread from 2018:

I have searched the internet for several days looking for information on the orientation of the two drum brake return springs on Bendix style brakes and have not found a definitive answer. My service manuals mention that it makes a difference but don't identify them and online tutorials just say...

www.binderplanet.com

From the above:

------------

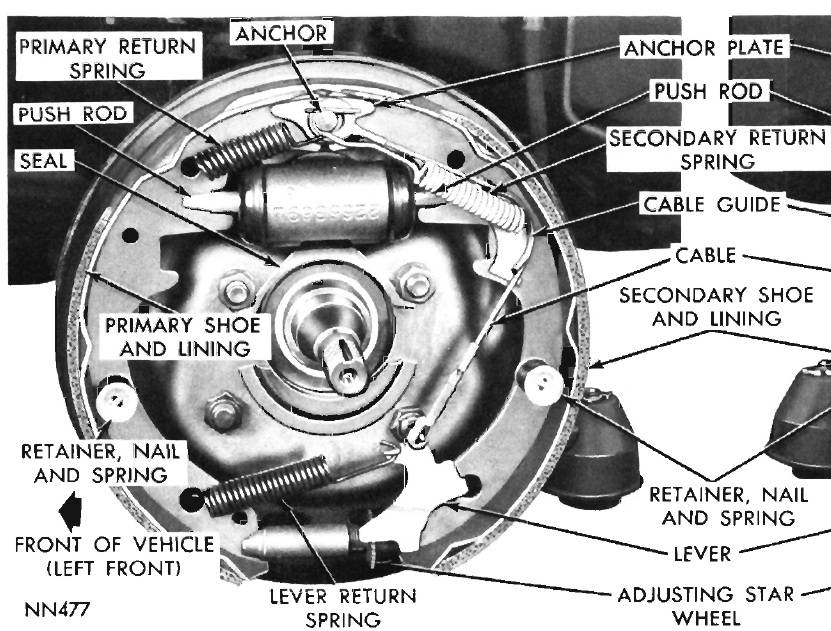

When braking, the primary (front) shoe moves away from the anchor pin, while the secondary shoe does so only momentarily or not at all. Because of the 'servo' action, the lower section of the secondary shoe moves outward against the drum and its upper end may also slide on the pin as that part also moves outward. The primary shoe's spring is pulling the shoe directly towards the pin, the secondary spring is working at a greater angle, pulling the rear of the shoe towards the axle center and perhaps also sliding the top of the shoe (which is against the pin) towards the axle center.

As I see it, this requires the stronger spring to be in the rear, on the secondary shoe. The primary spring stretches more but has an easier job pulling inline.

-----------

Dana, your description agrees with the only online reference I have been able to find. I quoted it below. Got this from a website named what-when-how.

==============

Duo-servo Brake

This brake arrangement is also known as the self-energizing brake. Although this is a very powerful brake, its effectiveness reduces severely with the decrease in the friction value. A hydraulically operated duo-servo brake is shown in Fig. 28.18. The principle of operation is based on the utilization of drum energy to considerably boost the force applied on the brakes by the driver.

When the leading shoe is pushed to contact the forward-moving drum, it rotates partially with the drum due to the frictional force. This shoe movement, produced by this self-wrapping action, is conveyed through a floating adjuster to the trailing shoe so that the shoe is brought into contact with the drum. The force applied by the expander is supplemented by the self-energizing action of both shoes.

To minimize the delay in application of the self-energization action, the trailing shoe is held on the anchor pin by a stronger return spring so that the expander only moves the leadingshoe. In this arrangement, the leading shoe is called the primary shoe, because this shoe is made to contact the drum before the secondary shoe.

================

There are several comments on forums and discussion groups that say just the opposite though. Their reasoning is along the lines of the stronger spring should be toward the front since it has to pull the shoe further once the brakes are being released.

--------------

I was thinking that they did away with the dual-springs (especially in the aftermarket spring kits) to avoid installation confusion and possibly botched DIY brake jobs. Someone in the above thread also mentions this.

I think what you want in these servo drum brakes is that one shoe moves first and contacts the drum while the other shoe is still firmly locked against the anchor pin. In this way both shoes act as a single solid shoe that arcs against the drum, and then the back shoe can be forced out by the piston if there's enough pressure applied.

In this scheme, it must be the forward or leading shoe that moves first, meaning that it should have a weaker return spring.