Remember, you're reading "advertising copy" not an engineering manual. Certainly, more accurate piston ring location is good. The skirt coatings are what many OEMs are using now, on non-forged pistons. As time has progressed, evolutionary changes in alloy, machining, etc. should always be going on. When they make a verified improvement in the product, the catalog dialogue reflects it.

Ask your engine builder how much skirt clearance those pistons specify. Only THEM can the "tighter tolerances" issue be determined. There's a late 1967 issue of "Hot Rod" magazine where they dyno a '67 383/325 motor. See how much power those stock cast pistons would make.

It used to be that the only upgrade from a cast piston was a forged piston. This was changed when the hypereutetic pistons were introduced. Same skirt clearance as cast pistons, strength of forged pistons.

A non-judgmental issue of many engine builders. By observation, they have a supply network they work with. Possibly even more than one. Each network has their particular brands of products. All good stuff, just different brands. If there might be something "out of network", it might need more effort to find some things, but if a similar product is available in network, they'll use and promote it if it worked well for them. Just how things are. So they use what they can get rather than look for something else. In this case, if your builder has a good source for the forged pistons, but not quality cast or hypereutetic pistons, he'll lean toward the forged pistons as a result. Nothing wrong with that at all, other than customer cost issues.

In building engines, we all want "the best" and "better than stock" with regard to many internal components. This is natural, but it also presumes that the stock items are not good, although they have lasted well past 100K miles with no problems. We all want to brag about the things in our engines, typically, so some normal upgrades (roller timing chains, windage trays, ignition systems) are easy to talk about. Add "forged pistons" and you've suddenly upgraded to "race engine items", in a basically stock engine.

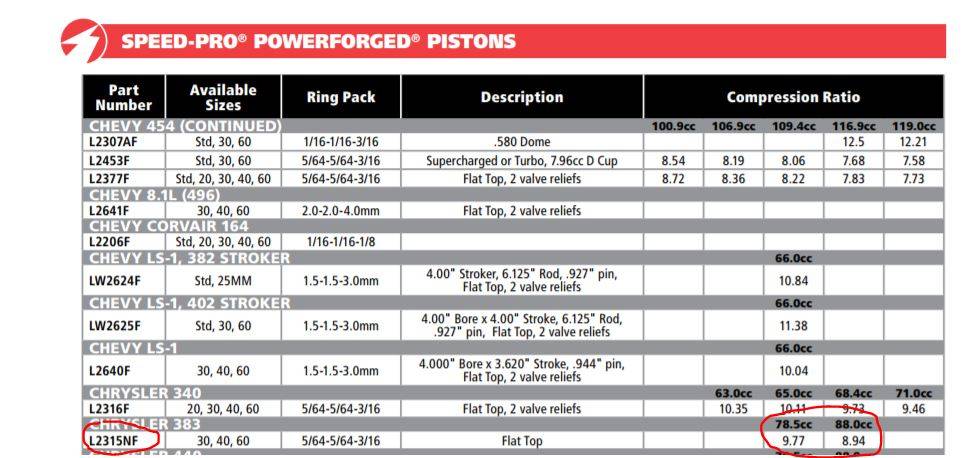

There is ONE compelling reason to use those particular pistons. Keeping the CR in the higher 9s, rather than higher 8s. Just be prepared to use 93 posted octane fuels if needed.

As an side note, as the pistons will usually have a different weight than the stock pistons the crank is balanced for, you'll need to get the rotating assy balanced. No matter whose pistons are used (other than Chrysler stock OEM-production pistons).

You're the one who has to be pleased in this deal. It's YOUR money, not ours.

Enjoy!

CBODY67