mr. fix it

Old Man with a Hat

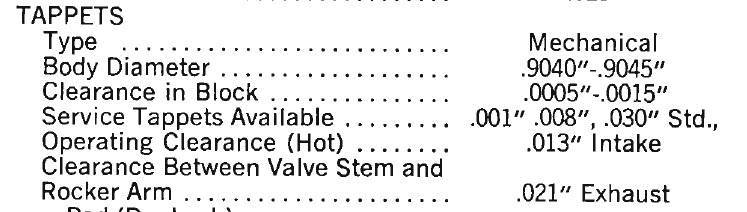

Ok so I'm smoothing out things here and see that the FSM states I should adjust the Rockers once the engine is up to operating temps.

I wanted to know if anyone has adjusted the tappetts doing this then after a good cool down checked the valve clearances...

If yes then,

1) What was you measurements taken?

2) were they varying greating from the hot adjustment?

3) Were they varying cylinder to cylinder greatly?

4) Or were they stable across all cylinders?

Let me know what you know!

Thanks!!

I wanted to know if anyone has adjusted the tappetts doing this then after a good cool down checked the valve clearances...

If yes then,

1) What was you measurements taken?

2) were they varying greating from the hot adjustment?

3) Were they varying cylinder to cylinder greatly?

4) Or were they stable across all cylinders?

Let me know what you know!

Thanks!!