monaco75

Senior Member

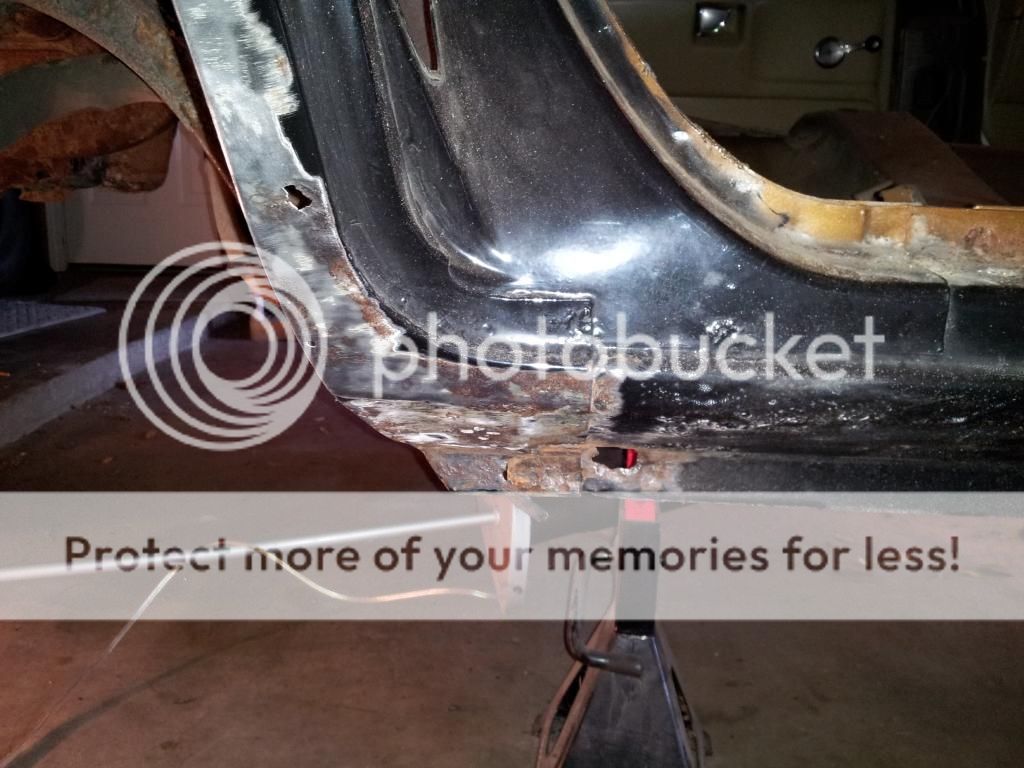

Welp, this is the best I'm going to get it I believe. The seam is not as bad as it looks. Its flush with the surrounding metal, and solid. I still have a pin hole to fill, and a couple small spots to grind down. Also wanna run a couple tacks along the backside, to be double sure its solid, and not gonna crack/fall apart from road vibration when shes back on the road. Then a bit of filler, and good to go.

Took the wire wheel to the surface rust, then a little primer.

Need to start on another panel to keep my interest up lol. Not sure what to do next.. Either the wheel well, or the few holes along the wheel arch in the quarter.

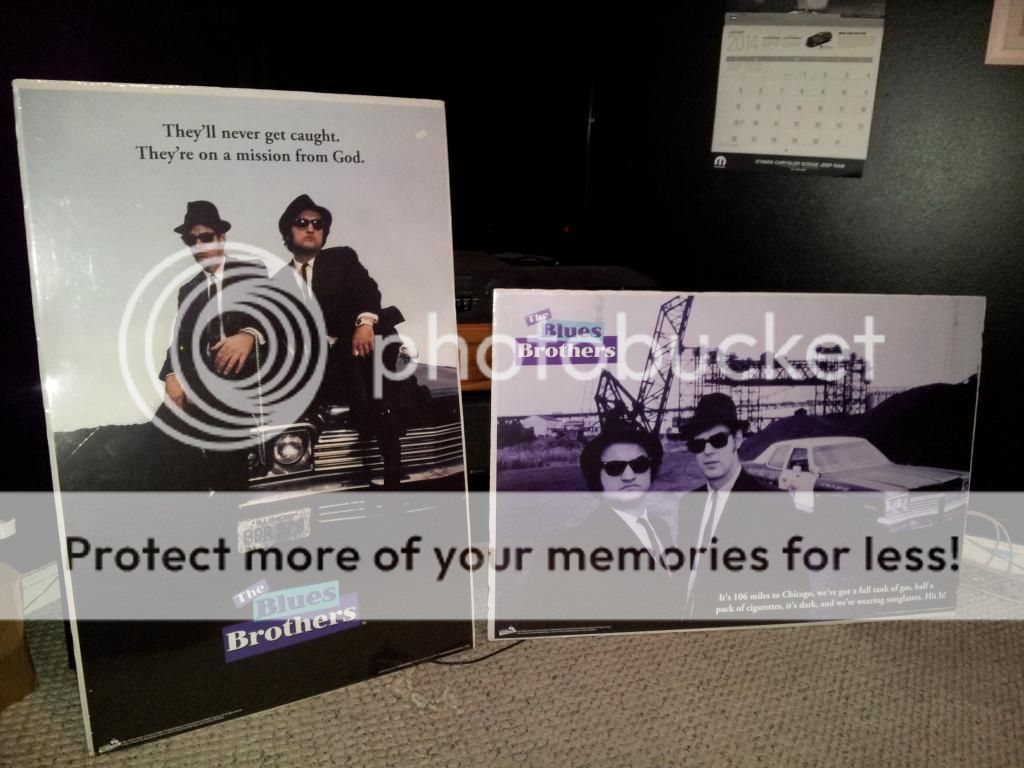

Found these bad boys in the smoke shop today, had to grab em!! Got one up on the wall. Need to find a spot for the other.

Edit- might help if I included the picture ehh??

Took the wire wheel to the surface rust, then a little primer.

Need to start on another panel to keep my interest up lol. Not sure what to do next.. Either the wheel well, or the few holes along the wheel arch in the quarter.

Found these bad boys in the smoke shop today, had to grab em!! Got one up on the wall. Need to find a spot for the other.

Edit- might help if I included the picture ehh??

Last edited: