Not slicks, just drag radials. The car runs 12.20@109.8, even running a tire that was over 2" shorter, the car went 12.20 from one year to the next. I have changed the govenor in the trans, and it now appear to shift at about 6200 vs the 5800-5900 it used to shift at (i leave it in drive when i race) the new lifters let it pull hard the extra 300 to 400 rpm. Also, remember these times are after a 80-ish mile drive to the track.You think MEV is trying to pull something on everyone here? It's not an exotic combo, and the numbers add up. 4800 lbs car, and lets be conservative and call it 550 hp. He is running Cal-Tracs and slicks on a prepped surface. Mid 12's all day. With some more aggressive gearing he could probably get into the 12-teens or better...but at the cost of highway driveability.

You want a 15 second recipe, stick with stock displacement, stock cast iron intake, shitty vac secondary carb, log manifolds, highway gears and a stock convertor. Presto, slow car, no magic.

Feel free to play with the 1/4 mile calc yourself. It does assume ideal traction, gearing etc, but after that the numbers are pretty close to reality if the car is well set up.

1/4 Mile ET Calculator

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

509 vs custom

- Thread starter Anthony 71 Paisley

- Start date

What gears, cu in, and converter MEV?

I saw a vid that said 505 and 3.23. Very impressive!

Anthony 71 Paisley

Member

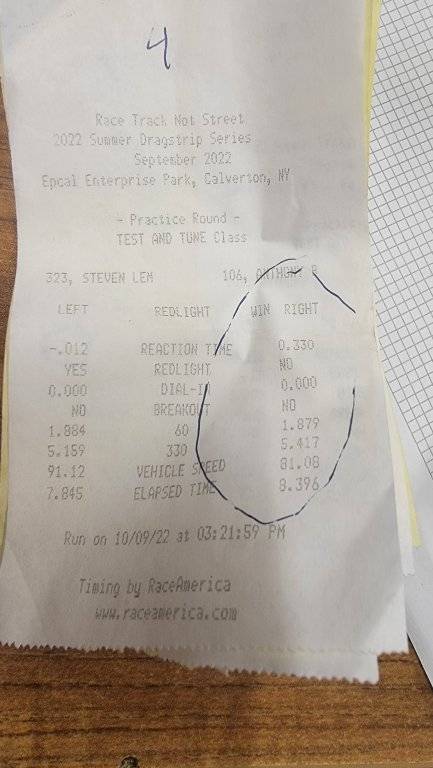

Figured id post an update. Got the motor swung in place in Sept of 21, Long Island Needs a Drag Strip & Pete Scalzo as well as many others were able to convince the town of Riverhead to allow us to run 1/8mile unprepped track for 8 weekends of 21 . I didn't have the time to get the bugs worked out before the last weekend of 21 but I was able to make a few trips in 22. Best pass of 8.39 at 81mph . I had some transmission issues I plan to work out through this winter. I'm confident I'll reach my goals of sub 13 sec if I can get the gremlins worked out. I did put a 9" rear and 4:10s in Feb of 22 it suits my needs pretty well I'll keep on tinkering until it's where I want It.

Blusmbl

Active Member

Converter can really make or break the combo, especially on a heavier car like a C body with a decent cam. I assume you’ll pick up some with the 4.10 swap. You’re in 12 second territory with that 60’ already!

For heavier street cars I’m not a fan of wide LSA cams. The narrow LSA that a lot of the older MP grinds had really helps midrange torque, as long as you can live with the degraded idle quality.

For heavier street cars I’m not a fan of wide LSA cams. The narrow LSA that a lot of the older MP grinds had really helps midrange torque, as long as you can live with the degraded idle quality.

Anthony 71 Paisley

Member

Yes, I'm it the limit of this convertor. I looked around a little bit for a slightly looser one I can't stomach the 1000$ price tag for a few extra rpm stall. I had Viper Transmission Parts loosen it up as much as it would go.Converter can really make or break the combo, especially on a heavier car like a C body with a decent cam. I assume you’ll pick up some with the 4.10 swap. You’re in 12 second territory with that 60’ already!

For heavier street cars I’m not a fan of wide LSA cams. The narrow LSA that a lot of the older MP grinds had really helps midrange torque, as long as you can live with the degraded idle quality.

I never ran it with the 3.91 gears only the 4.10 I was pretty happy with the 60ft times on my best pass.

I/we went with the 112lsa as to not give me tuning issues with the Fitech. I think about it every now and then swapping it for a 110 to see if i can live with it. But cam swap for me is closer to the bottom of my list.

Blusmbl

Active Member

Oh yeah- the wide LSA stuff is not self-learn EFI friendly at all. From what I recall with a Holley, a narrow LSA cam like that requires being in open loop below 2500 rpm.

Super cool Fury!!

Super cool Fury!!

Anthony 71 Paisley

Member

ThanksOh yeah- the wide LSA stuff is not self-learn EFI friendly at all. From what I recall with a Holley, a narrow LSA cam like that requires being in open loop below 2500 rpm.

Super cool Fury!!

Considering that a lot of OEM camshafts, even the HP versions, were about 114 degree LSA cams, does that mean that a Holley Sniper EFI system will not work with those stock cams? Or not work well?

Please help me understand that as an EFI system sprays the incoming air with fuel whether directly into the intake manifold ports a throttle body. Then the amount of spray is modulated by the oxygen sensor near an/the exhaust manifold down pipe, within set parameters. How does the cam LSA come into play?

Just curious,

CBODY67

Please help me understand that as an EFI system sprays the incoming air with fuel whether directly into the intake manifold ports a throttle body. Then the amount of spray is modulated by the oxygen sensor near an/the exhaust manifold down pipe, within set parameters. How does the cam LSA come into play?

Just curious,

CBODY67

Anthony 71 Paisley

Member

I'm sure others can explain better but pretty much with a choppy idle the Fitech has a hard time getting a steady signal to deliver fuel properly. It tries to regulate to to whatever Afr parameters the user plugs in instead of a carb pulling fuel without regard.Considering that a lot of OEM camshafts, even the HP versions, were about 114 degree LSA cams, does that mean that a Holley Sniper EFI system will not work with those stock cams? Or not work well?

Please help me understand that as an EFI system sprays the incoming air with fuel whether directly into the intake manifold ports a throttle body. Then the amount of spray is modulated by the oxygen sensor near an/the exhaust manifold down pipe, within set parameters. How does the cam LSA come into play?

Just curious,

CBODY67

A stock cam would work excellent, when you get into narrow lsa is where it becomes an issue. Although there are plenty of guys running WAY more radical cams then I am.

65sporty

Old Man with a Hat

EFI looks at more than the O2 sensor, is it open or closed loop? Coolant temp, throttle position, MAP sensor, O2, it also may have control of the timing curve depending on what distributor is being used.Considering that a lot of OEM camshafts, even the HP versions, were about 114 degree LSA cams, does that mean that a Holley Sniper EFI system will not work with those stock cams? Or not work well?

Please help me understand that as an EFI system sprays the incoming air with fuel whether directly into the intake manifold ports a throttle body. Then the amount of spray is modulated by the oxygen sensor near an/the exhaust manifold down pipe, within set parameters. How does the cam LSA come into play?

Just curious,

CBODY67

Certainly, there ARE more items the computer looks at other than oxygen content of the exhaust gases. That's a given, but those items tend to be more fine-tuning aspects of things, I suspect, of what the oxygen sensor sees.

Blusmbl

Active Member

Yeah, I mistyped. I meant narrow LSA. 114 is great for EFI. Something like a 105 is not.

65sporty

Old Man with a Hat

Certainly, there ARE more items the computer looks at other than oxygen content of the exhaust gases. That's a given, but those items tend to be more fine-tuning aspects of things, I suspect, of what the oxygen sensor sees.

In open loop it will run a fixed map that is usually based on throttle position, coolant temp, MAP sensor for load and yes, O2 sensor. The LSA will effect vacuum which in turn effects the MAP. All this can be tuned of course. The big issue was when in the late 80's and early 90's when guy's tried to run a 110 LSA on stock tuned EFI and the computer didn't like the low vacuum signal. This is all speed density a MAF system is less dependent on vacuum signal

Blusmbl

Active Member

It’s also not just the low vacuum signal- at low engine speeds and throttle positions, you can’t always trust the oxygen sensor reading as the exhaust valve overlap with the intake will draw unburnt fuel + air through the exhaust and make the oxygen sensor read incorrectly, it's not accurately reflecting the combustion event anymore. You can get around it by forcing it to open loop in those scenarios.

One issue might be whether the OEM cast iron exhaust manfiods are on the engine or "collectored" headers? In an OEM-style cast iron exhaust manifold, usually tending toward a log-style manifold, there are a LOT of pressure variations in that exhaust manifold at low rpms, although what comes out of the tail pipe is smooth.

This reversion can result in charge dilution of the fresh intake air/fuel mixture from the intake manifold. Charge dilution which can be the same as a "designed-in EGR" of sorts. One reason that some newer cam specs for emissions-controlled engines had more duration and overlap than the prior cams in the same motor did. As the additional duration and lift made more power to hopefully compensate for the lower compression ratios of that time.

One way of addressing the reversion was the development and sale of "anti-reversion headers" of the earlier 1980s or so. Each port at the header flange had an additional anti-reversion cone to minimize charge dilution. But it also might have hampered ultimate exhaust flow as it ws a trend that died a somewhat quick death. At that time, people bought headers for their horsepower building capabilities, not part-throttle efficiency.

The other issue with the AR headers was that each pipe at the flange was straight for about three inches of distance away from the flange, then it curved to head to the collectors. Unlike normal headers which would make that same curve within one inch of the flange. Packaging issues in some cases, especially on some model years with factory a/c.

Happy Holidays!

CBODY67

This reversion can result in charge dilution of the fresh intake air/fuel mixture from the intake manifold. Charge dilution which can be the same as a "designed-in EGR" of sorts. One reason that some newer cam specs for emissions-controlled engines had more duration and overlap than the prior cams in the same motor did. As the additional duration and lift made more power to hopefully compensate for the lower compression ratios of that time.

One way of addressing the reversion was the development and sale of "anti-reversion headers" of the earlier 1980s or so. Each port at the header flange had an additional anti-reversion cone to minimize charge dilution. But it also might have hampered ultimate exhaust flow as it ws a trend that died a somewhat quick death. At that time, people bought headers for their horsepower building capabilities, not part-throttle efficiency.

The other issue with the AR headers was that each pipe at the flange was straight for about three inches of distance away from the flange, then it curved to head to the collectors. Unlike normal headers which would make that same curve within one inch of the flange. Packaging issues in some cases, especially on some model years with factory a/c.

Happy Holidays!

CBODY67

Similar threads

- Replies

- 2

- Views

- 2K

- Replies

- 49

- Views

- 19K

- Replies

- 34

- Views

- 7K

- Replies

- 5

- Views

- 2K